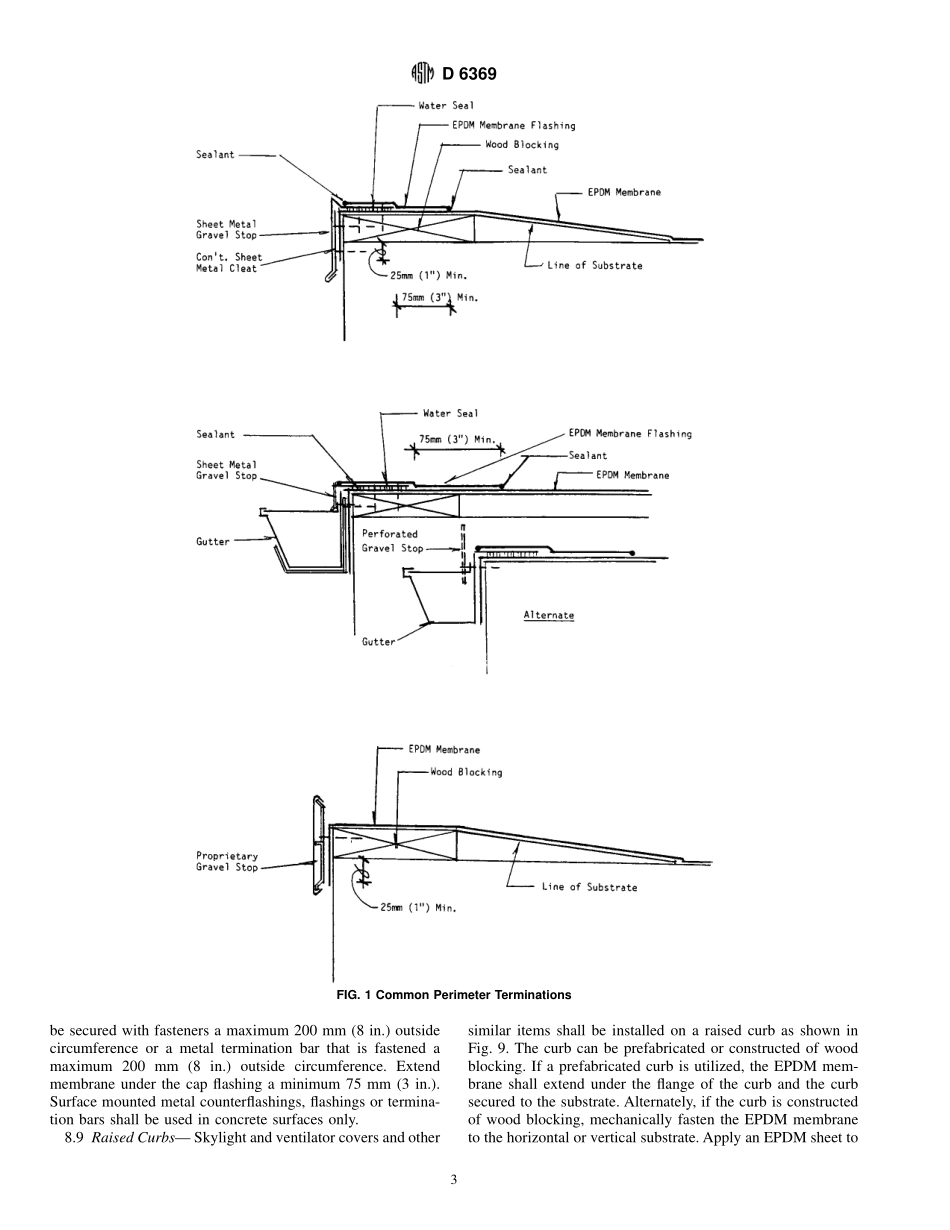

Designation:D6369–99StandardGuideforDesignofStandardFlashingDetailsforEPDMRoofMembranes1ThisstandardisissuedunderthefixeddesignationD6369;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisguidecoversthedesignofdetailsfortypicalconditionsencounteredinnewballasted,mechanicallyat-tachedorfullyadheredethylenepropylenedieneterpolymer(EPDM)sheetroofsystems.1.2Thisguideillustratesgeneraldetailsfortypicalcondi-tionsthatmaybeencounteredonanEPDMsheetroofingsystem.Theguidewillassistthedesignerinpreparingdetailsforeachspecificconditionthatmayoccuronaproject.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Theconventionalunitsgiveninparenthesesareprovidedforinformationpurposesonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:D1079TerminologyRelatingtoRoofing,WaterproofingandBituminousMaterials23.Terminology3.1Definitions—Fordefinitionsoftermsusedinthisguideandnotlistedbelow,seeTerminologyD1079.3.2ballastedsheetroofing,n—asystemwhichincorporatesalooselaidvulcanizedEPDMsheetoveranacceptedsubstrateandisheldinplacewitheitherstoneballast,pavers,oracombinationthereof.3.3fullyadheredsheetroofing,n—asystemwhichincor-poratesavulcanizedEPDMsheetfullyadheredoverasecuredandacceptedsubstrate.3.4mechanicallyattachedsheetroofing,n—asystemwhichincorporatesamechanicallyfastenedvulcanizedEPDMsheetoverasecuredandacceptedsubstrate.4.SignificanceandUse4.1Thisguideillustratesgeneraldetailsfortypicalcondi-tionsthatmaybeencounteredonanEPDMsheetroofingsystem.4.2ThisguidedoesnotaddressallrequirementsassociatedwiththeinstallationofEPDMmembraneflas...