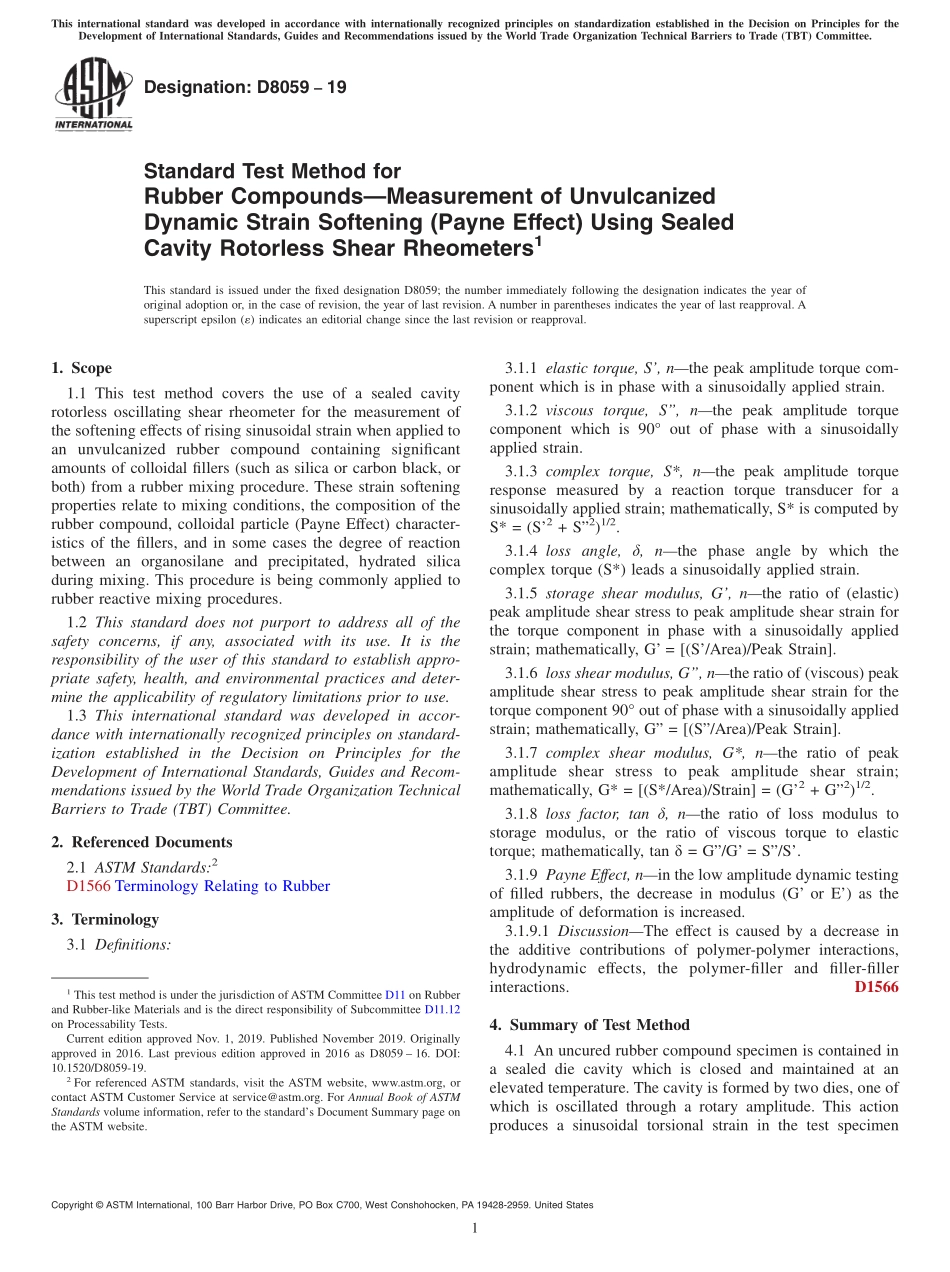

Designation:D8059−19StandardTestMethodforRubberCompounds—MeasurementofUnvulcanizedDynamicStrainSoftening(PayneEffect)UsingSealedCavityRotorlessShearRheometers1ThisstandardisissuedunderthefixeddesignationD8059;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoverstheuseofasealedcavityrotorlessoscillatingshearrheometerforthemeasurementofthesofteningeffectsofrisingsinusoidalstrainwhenappliedtoanunvulcanizedrubbercompoundcontainingsignificantamountsofcolloidalfillers(suchassilicaorcarbonblack,orboth)fromarubbermixingprocedure.Thesestrainsofteningpropertiesrelatetomixingconditions,thecompositionoftherubbercompound,colloidalparticle(PayneEffect)character-isticsofthefillers,andinsomecasesthedegreeofreactionbetweenanorganosilaneandprecipitated,hydratedsilicaduringmixing.Thisprocedureisbeingcommonlyappliedtorubberreactivemixingprocedures.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.3Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D1566TerminologyRelatingtoRubber3.Terminology3.1Definitions:3.1.1elastictorque,S’,n—thepeakamplitudetorquecom-ponentwhichisinphasewithasinusoidallyappliedstrain.3.1.2viscoustorque,S”,n—thepeakamplitudetorquecomponentwhichis90°outofphasewithasinusoidallyappliedstrain.3.1.3complextorque,S*,n—thepeakamplitudetorqueresponsemeasuredbyare...