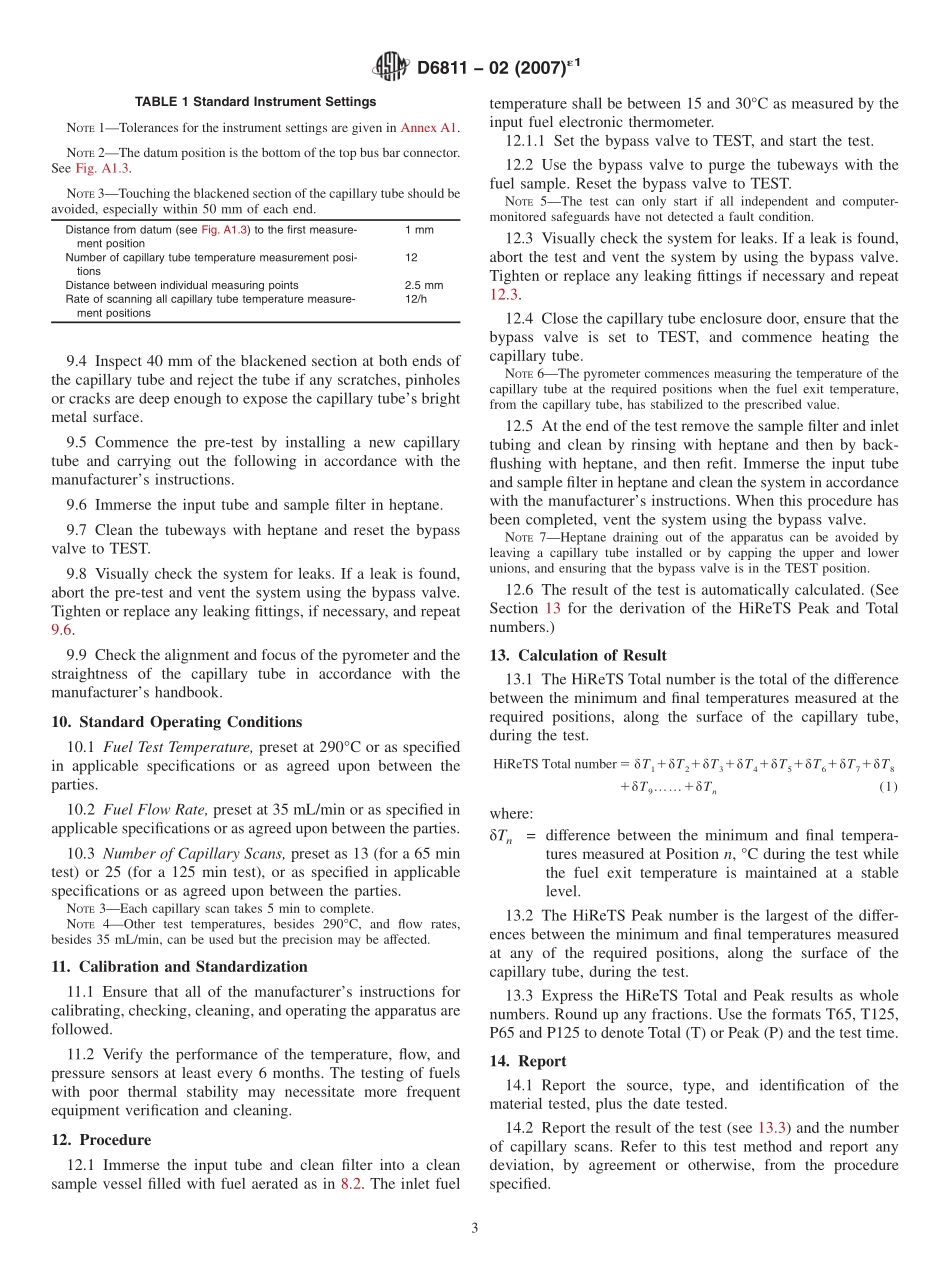

Designation:D6811−02(Reapproved2007)´1StandardTestMethodforMeasurementofThermalStabilityofAviationTurbineFuelsunderTurbulentFlowConditions(HiReTSMethod)1,2ThisstandardisissuedunderthefixeddesignationD6811;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ε1NOTE—RemovedallinstancesoftheacronymforJetFuelThermalOxidationTestereditoriallyinApril2010.1.Scope1.1Thistestmethodcoversalaboratorythermalprocess,3usingaspecifiedapparatusformeasuringthetendenciesofaviationturbinefuelstodepositinsolublematerialsandde-compositionproducts,suchaslacquers,withinafuelsystem.Thistestmethodprovidesaquantitativeresultforfuelunderturbulentflowconditionsin65or125min.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:4D3241TestMethodforThermalOxidationStabilityofAviationTurbineFuelsD4057PracticeforManualSamplingofPetroleumandPetroleumProductsD4177PracticeforAutomaticSamplingofPetroleumandPetroleumProductsD4306PracticeforAviationFuelSampleContainersforTestsAffectedbyTraceContaminationE128TestMethodforMaximumPoreDiameterandPerme-abilityofRigidPorousFiltersforLaboratoryUse3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1capillarytube,n—acoatedresistivelyheatedstainlesssteeltubethroughwhichfuelispumpedandcontrolledtogiveapredefinedconstantfuelexittemperature.3.1.2deposits,n—oxidativeproducts,suchaslacquers,laiddownpredominantlyatthefuelexitend(hottest),ontheinsideoftheheatedcapillarytube.3.1.3HiReTS,n—highReynoldsnumberthermalstability.3.1.4HiReTSPeak(P)numberandTotal(T)number,n—thequanti...