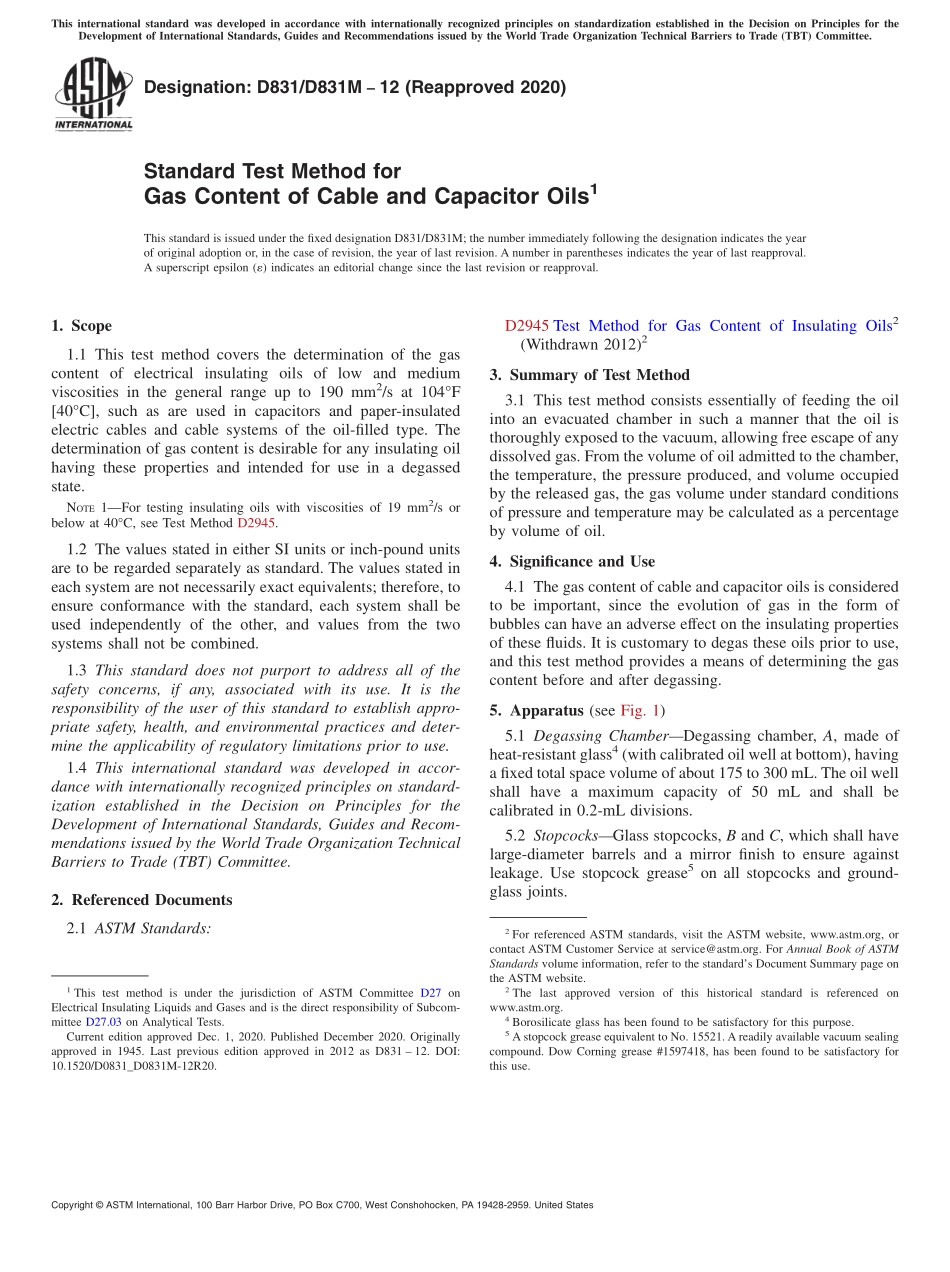

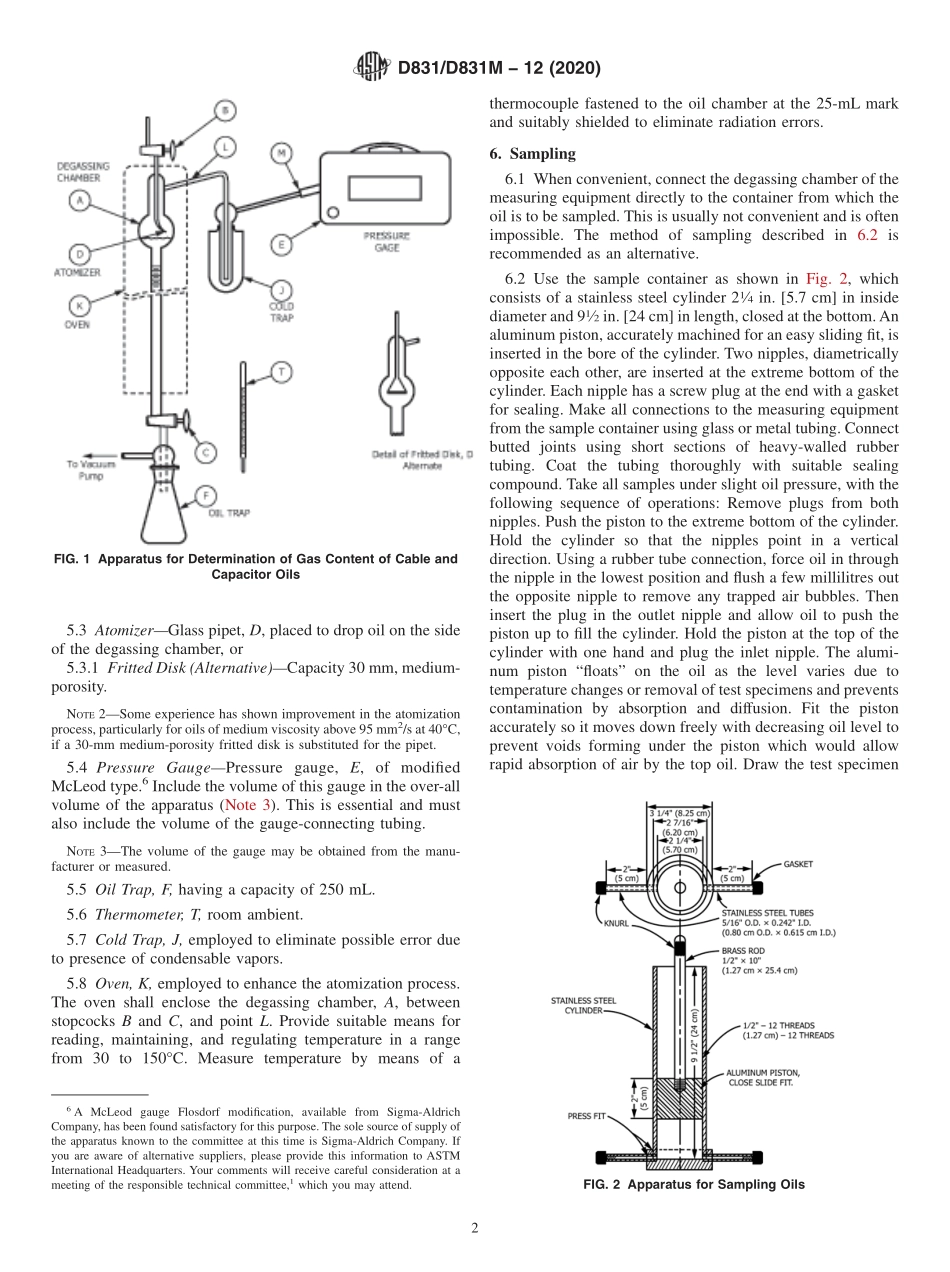

Designation:D831/D831M−12(Reapproved2020)StandardTestMethodforGasContentofCableandCapacitorOils1ThisstandardisissuedunderthefixeddesignationD831/D831M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthegascontentofelectricalinsulatingoilsoflowandmediumviscositiesinthegeneralrangeupto190mm2/sat104°F[40°C],suchasareusedincapacitorsandpaper-insulatedelectriccablesandcablesystemsoftheoil-filledtype.Thedeterminationofgascontentisdesirableforanyinsulatingoilhavingthesepropertiesandintendedforuseinadegassedstate.NOTE1—Fortestinginsulatingoilswithviscositiesof19mm2/sorbelowat40°C,seeTestMethodD2945.1.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemarenotnecessarilyexactequivalents;therefore,toensureconformancewiththestandard,eachsystemshallbeusedindependentlyoftheother,andvaluesfromthetwosystemsshallnotbecombined.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:D2945TestMethodforGasContentofInsulatingOils2(Withdrawn2012)23.SummaryofTestMethod3.1Thistestmethodconsistsessentiallyoffeedingtheoilintoanevacuatedchamberinsuchamannerthattheoilisthoroughlyexposedtothevacuum,allowingfreeescapeofanydissolvedgas.Fromthevolumeofoiladmittedtoth...