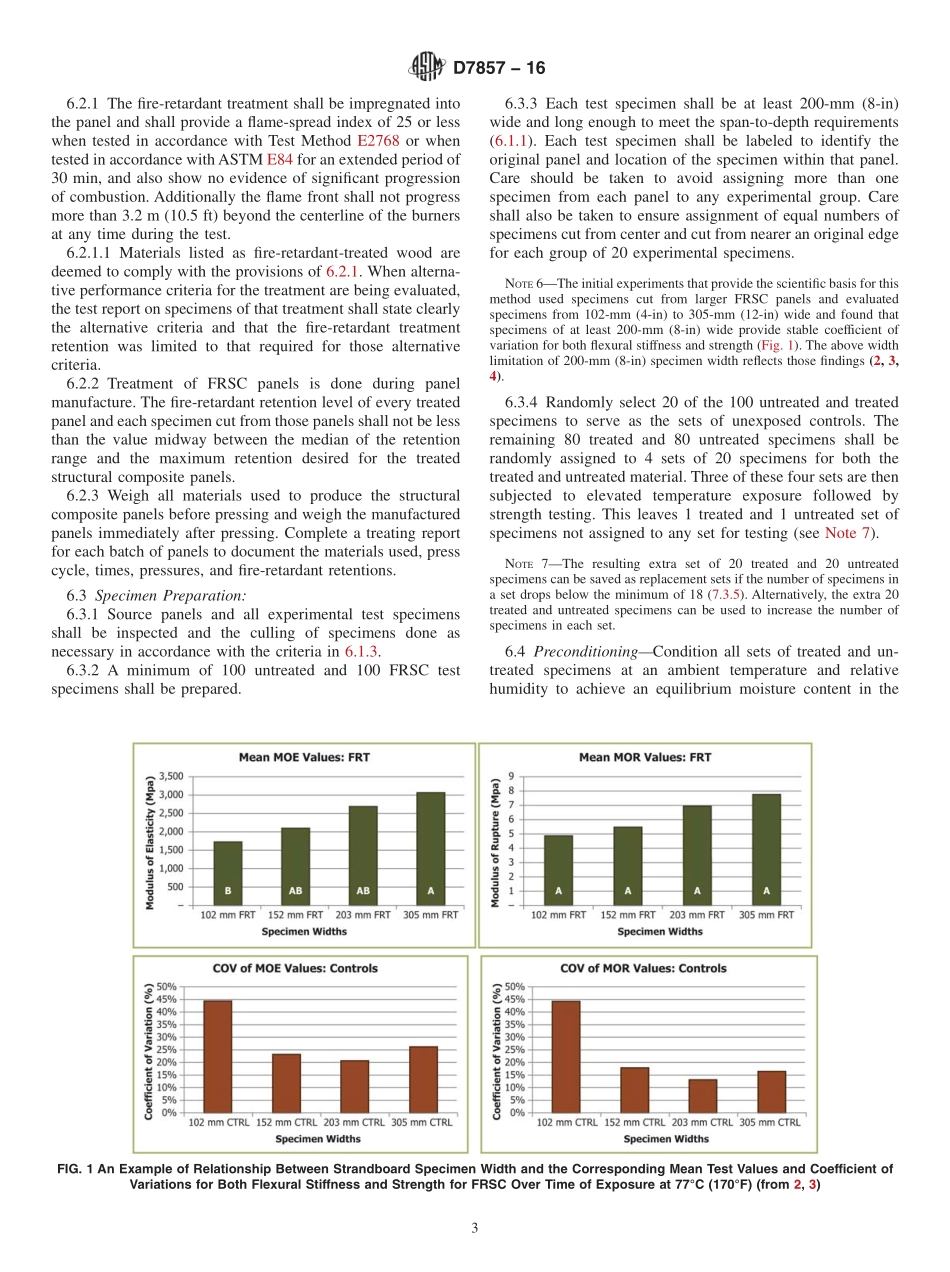

Designation:D7857−16StandardTestMethodforEvaluatingtheFlexuralPropertiesandInternalBondStrengthofFire-RetardedMat-FormedWoodStructuralCompositePanelsExposedtoElevatedTemperatures1ThisstandardisissuedunderthefixeddesignationD7857;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodisdesignedasalaboratoryscreeningtest.Itisintendedtoestablishanunderstandingoftherespectivecontributionsofthemanywoodmaterial,fire-retardant,resinandprocessingvariables,andtheirinteractions,uponthemechanicalpropertiesoffire-retardedmat-formedwoodstructuralcomposite(FRSC)panelsastheyaffectflexuralandinternalbond(IB)performanceandastheyareoftenaffectedlaterduringexposuretohightemperatureandhumidity.Oncethecriticalmaterialandprocessingvariableshavebeenidentifiedthroughthesesmall-specimenlaboratoryscreeningtests,additionaltestingandevaluationshallberequiredtodeterminetheeffectofthetreatmentonthepanelstructuralpropertiesandtheeffectofexposuretohightem-peratureonthepropertiesofcommerciallyproducedFRSCpanels.Inthistestmethod,treatedstructuralcompositepanelsareexposedtoatemperatureof77°C(170°F)andatleast50%relativehumidity.1.2Thepurposeofthepreliminarylaboratory-basedtestmethodistocomparetheflexuralpropertiesandIBstrengthofFRSCpanelsrelativetountreatedstructuralcompositepanelswithotherwiseidenticalmanufacturingparameters.Theresultsoftestsconductedinaccordancewiththistestmethodprovideareferencepointforestimatingstrengthtemperaturerelation-shipsforpreliminarypurposes.Theyestablishastartingpointforsubsequentfull-scaletestingofcommerciallyproducedFRSCpanels.1.3Thistestmethoddoesnotcovertestingandevaluationrequirementsnecessaryforproductcertificationandqualifica-tionortheestablishmentofdesignvalueadjustmentfactorsforFRSCpanels.NOTE1—Onepotentiallyconfoundinglimitationofthi...