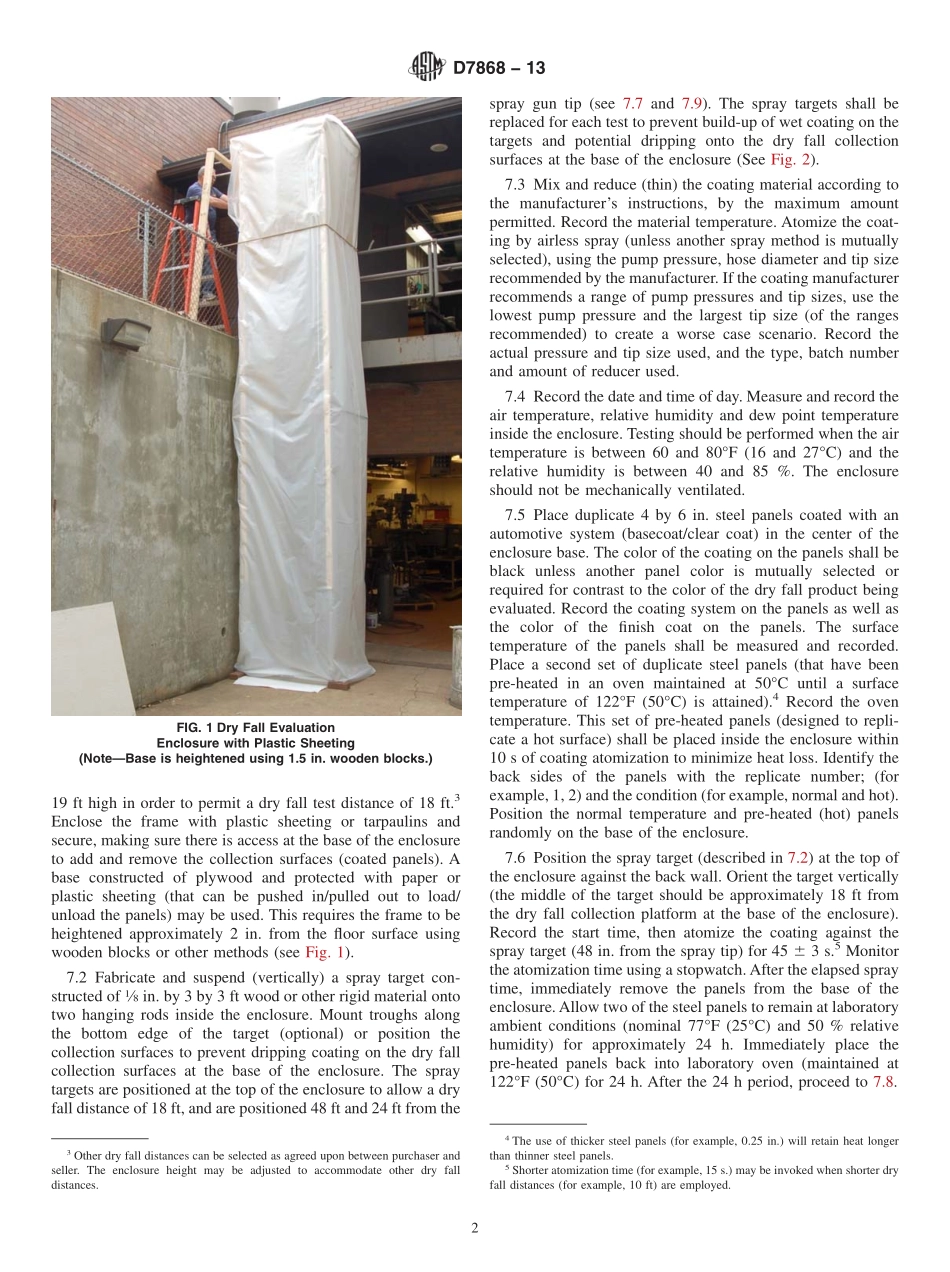

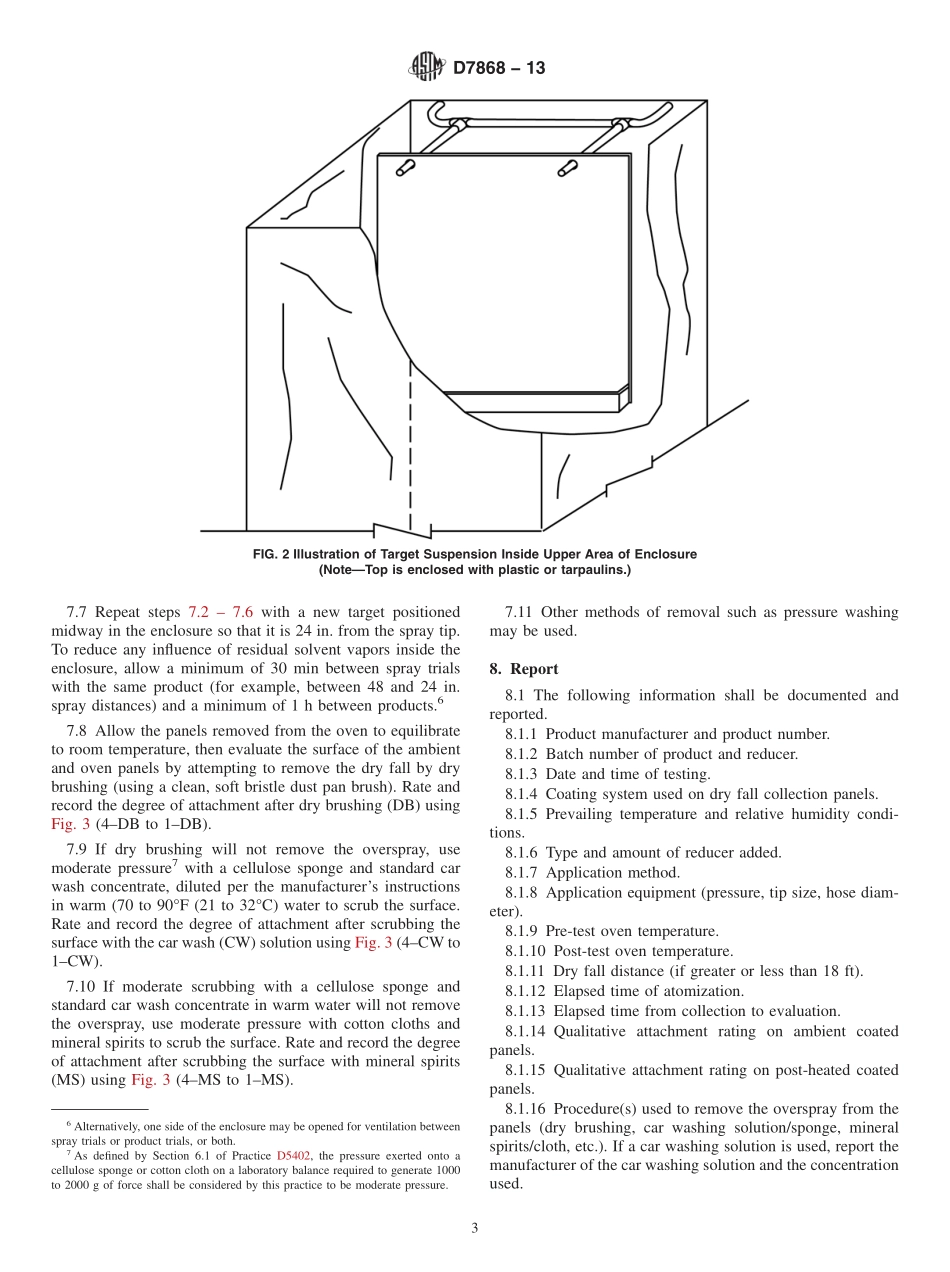

Designation:D7868−13StandardPracticeforDeterminingtheDryFall(Fog)PropertiesofProtectiveCoatings1ThisstandardisissuedunderthefixeddesignationD7868;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoversaprocedureforqualitativelyevalu-atingthedryfallpropertiesofcoatings.Theestablishmentofthetestenvironmentandtheevaluationproceduresarede-scribed.1.2Thispracticeusespanelscontaininganautomotivefinishsincethesetypesofsurfacesareoftentheprimaryconcernrelatingtooverspraydamage.Panelscoatedwithothersystemsmaybeusedascollectionsurfaceswhentheyaredeemedtobemorerepresentative.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D610PracticeforEvaluatingDegreeofRustingonPaintedSteelSurfacesD5402PracticeforAssessingtheSolventResistanceofOrganicCoatingsUsingSolventRubs3.Terminology3.1Definitions:3.1.1dry/fall/fogcoating,n—aninteriororexteriorcoatingspeciallyformulatedsothatthefineparticlesofoverspraydrytoadustorpowderduringafreefallofacertaindistanceatspecifictemperatureandhumidityranges,andwillnotadheretosurfacesonwhichtheoversprayissubsequentlydeposited.4.SummaryofPractice4.1Astructuralframeiserectedandenclosed.Spraytargetsareplacedinsidetheenclosure.Foursteelpanelscoatedwithanautomotivebasecoat/clearcoatsystemareplacedontheenclosurefloortocollectthedryfall.(Panelscoatedwithothersystemsoruncoatedpanels,orboth,canbeusedwhentheyaredeemedtobemorer...