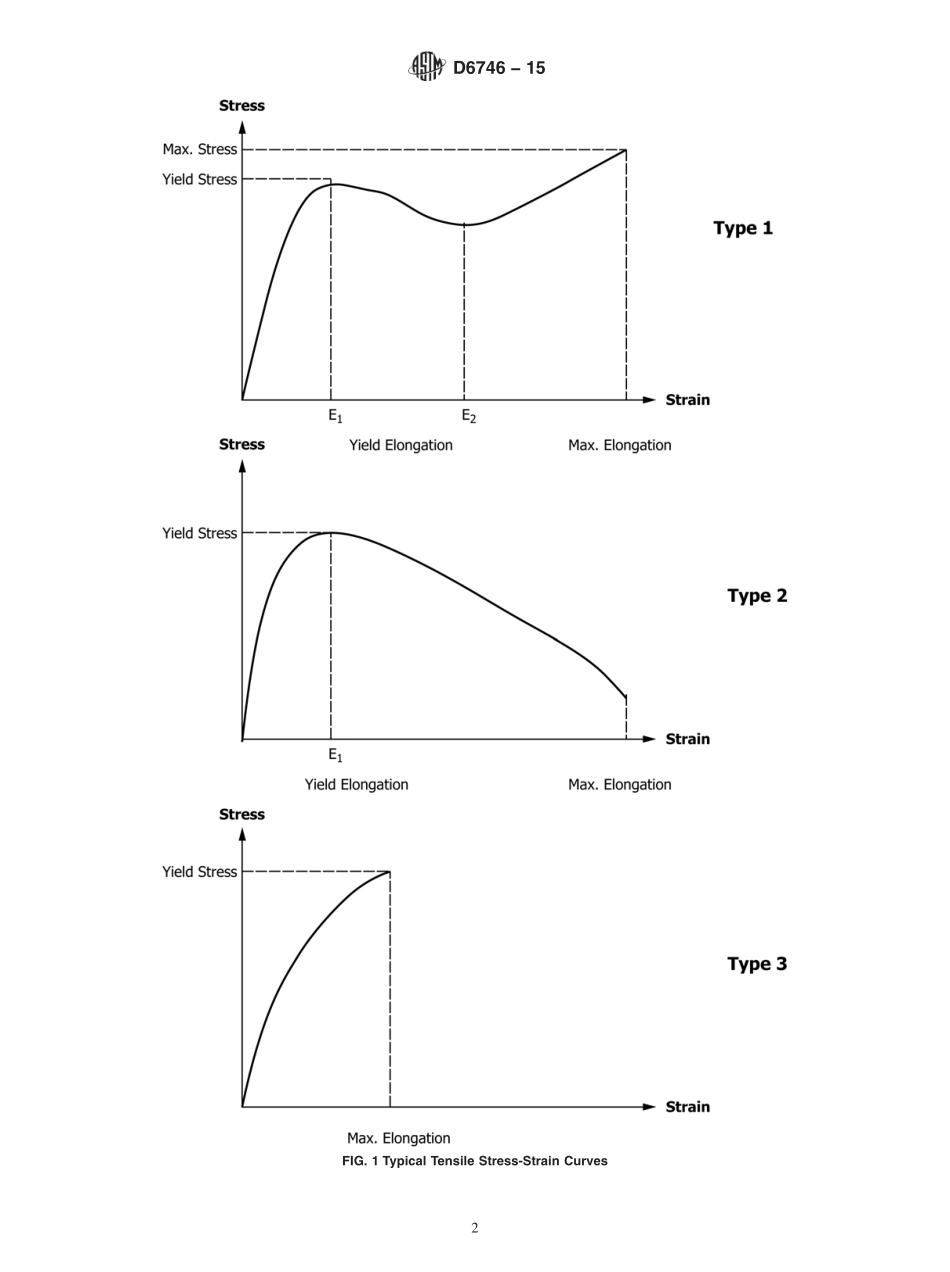

Designation:D6746−15StandardTestMethodforDeterminationofGreenStrengthandStressRelaxationofRawRubberorUnvulcanizedCompounds1ThisstandardisissuedunderthefixeddesignationD6746;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversmethodstoevaluateacharac-teristicofrawrubberorunvulcanizedrubbercompoundsthatisdesignatedasgreenstrength.Thisspecialstrengthpropertyforuncuredrubbersisanimportantprocessingperformanceattributeinrubberproductmanufacturing.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D412TestMethodsforVulcanizedRubberandThermoplas-ticElastomers—TensionD1349PracticeforRubber—StandardConditionsforTest-ingD3182PracticeforRubber—Materials,Equipment,andPro-ceduresforMixingStandardCompoundsandPreparingStandardVulcanizedSheetsD4483PracticeforEvaluatingPrecisionforTestMethodStandardsintheRubberandCarbonBlackManufacturingIndustries3.Terminology3.1Definitions:3.1.1greenstrength,n—acharacteristicpropertyofaraworunvulcanizedrubbercompoundthatindicatesresistancetodeformationwhenstressisapplied.3.1.1.1Discussion—Theword“green,”appliedtorubber,isasynonymforuncuredorunvulcanizedrubber.3.1.2tensilegreenmodulus,n—ratioofstresstostrainofaraworunvulcanizedrubbercompoundthatindicatesresistancetotensiledeformationorstrain.3.1.3tensilegreenstrength,n—yieldstressofaraworunvulcanizedrubbercompoundthatindicateslossofresistancetotensiledeformationorstress.4.SummaryofTestMethod4.1Thistestmethodisdividedintotwoparts...