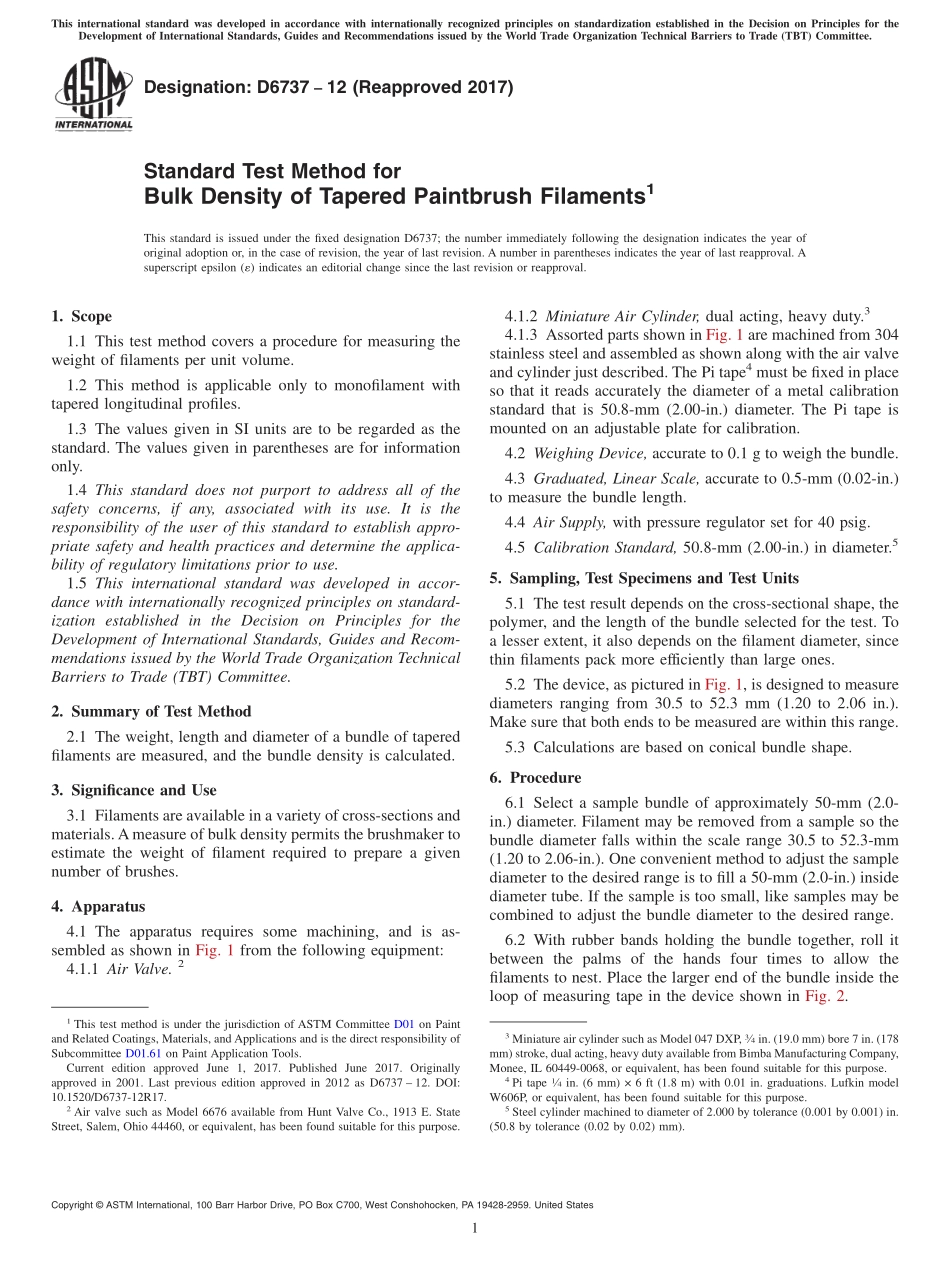

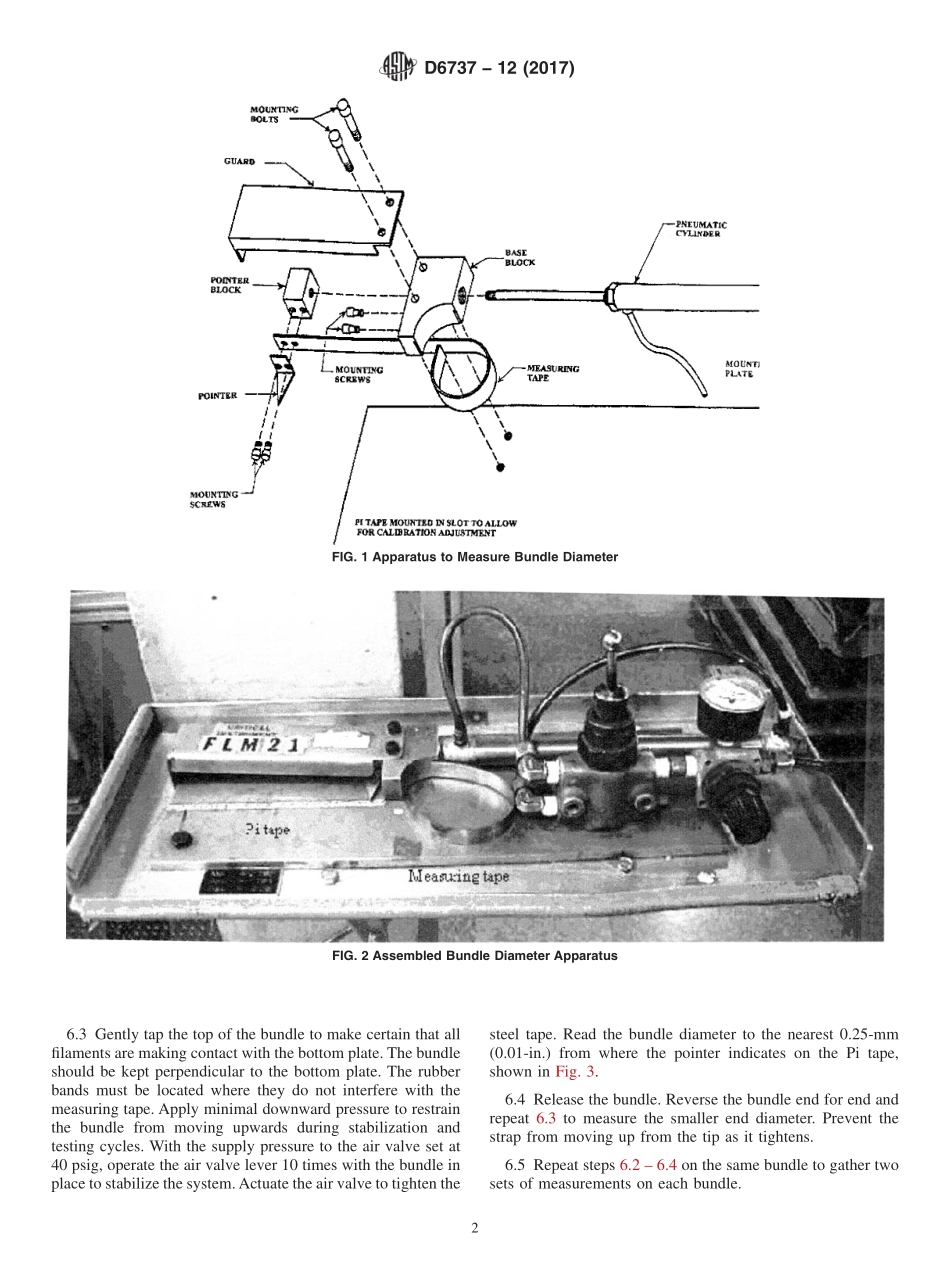

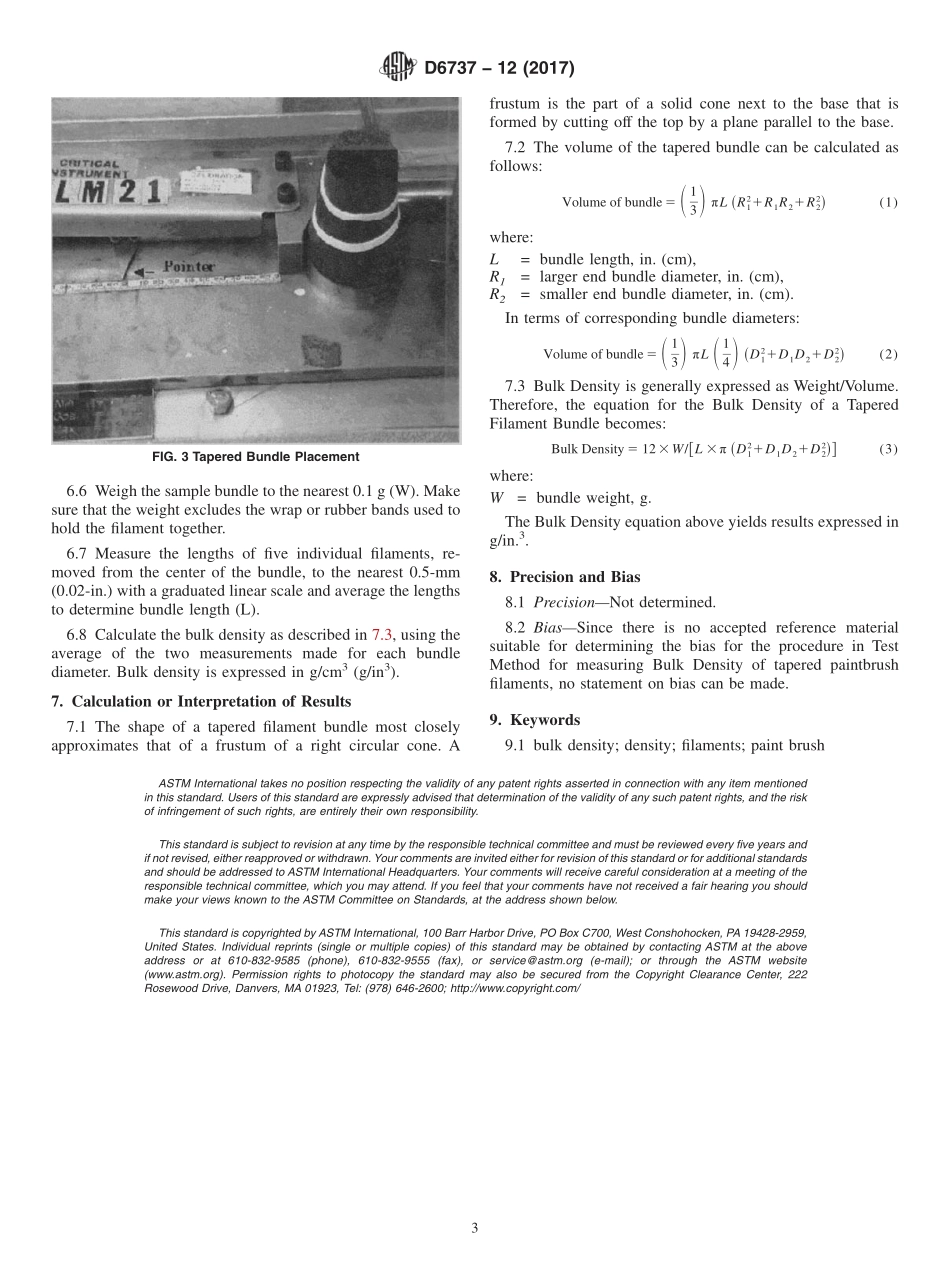

Designation:D6737−12(Reapproved2017)StandardTestMethodforBulkDensityofTaperedPaintbrushFilaments1ThisstandardisissuedunderthefixeddesignationD6737;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversaprocedureformeasuringtheweightoffilamentsperunitvolume.1.2Thismethodisapplicableonlytomonofilamentwithtaperedlongitudinalprofiles.1.3ThevaluesgiveninSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.SummaryofTestMethod2.1Theweight,lengthanddiameterofabundleoftaperedfilamentsaremeasured,andthebundledensityiscalculated.3.SignificanceandUse3.1Filamentsareavailableinavarietyofcross-sectionsandmaterials.Ameasureofbulkdensitypermitsthebrushmakertoestimatetheweightoffilamentrequiredtoprepareagivennumberofbrushes.4.Apparatus4.1Theapparatusrequiressomemachining,andisas-sembledasshowninFig.1fromthefollowingequipment:4.1.1AirValve.24.1.2MiniatureAirCylinder,dualacting,heavyduty.34.1.3AssortedpartsshowninFig.1aremachinedfrom304stainlesssteelandassembledasshownalongwiththeairvalveandcylinderjustdescribed.ThePitape4mustbefixedinplacesothatitreadsaccuratelythediameterofametalcalibrationstandardthatis50.8-mm(2.00-in.)diameter.ThePitapeismountedonanadjustableplateforcalibration.4.2WeighingDevice,acc...