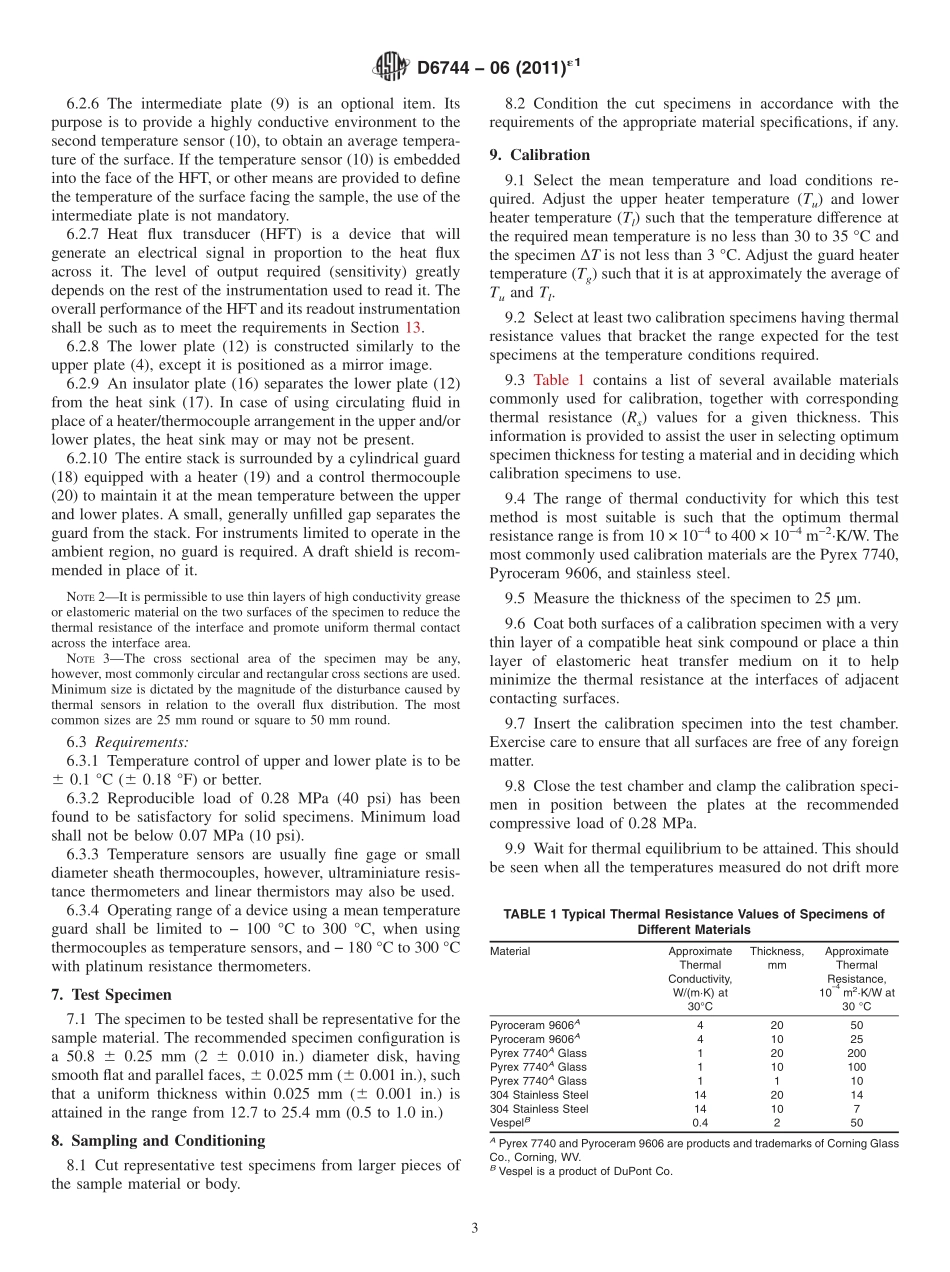

Designation:D6744−06(Reapproved2011)´1StandardTestMethodforDeterminationoftheThermalConductivityofAnodeCarbonsbytheGuardedHeatFlowMeterTechnique1ThisstandardisissuedunderthefixeddesignationD6744;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ε1NOTE—UpdatewordinginNotes1–4,6.3.2,12.1.8,andupdatednotationinSection13editoriallyinAugust2011.1.Scope1.1Thistestmethodcoversasteady-statetechniqueforthedeterminationofthethermalconductivityofcarbonmaterialsinthicknessesoflessthan25mm.Thetestmethodisusefulforhomogeneousmaterialshavingathermalconductivityintheapproximaterange1<λ<30W/(m·K),(thermalresistanceintherangefrom10to400×10−4m2·K/W)overtheapproxi-matetemperaturerangefrom150to600K.Itcanbeusedoutsidetheserangeswithreducedaccuracyforthickerspeci-mensandforthermalconductivityvaluesupto60W/(m·K).NOTE1—Itisnotrecommendedtotestgraphitecathodematerialsusingthistestmethod.Graphitesusuallyhaveaverylowthermalresistance,andtheinterfacesbetweenthespecimentobetestedandtheinstrumentbecomemoresignificantthanthespecimenitself.1.2ThistestmethodissimilarinconcepttoTestMethodsE1530andC518.Significantattentionhasbeenpaidtoensurethatthethermalresistanceofcontactingsurfacesisminimizedandreproducible.1.3ThevaluesstatedinSIunitsareregardedasstandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C518TestMethodforSteady-StateThermalTransmissionPropertiesbyMeansoftheHeatFlowMeterApparatusE1530TestMethodforEvaluatingtheResistancetoTher-malTransmissionofMaterialsbytheGuardedHeatFlowMeterTechnique3.Ter...