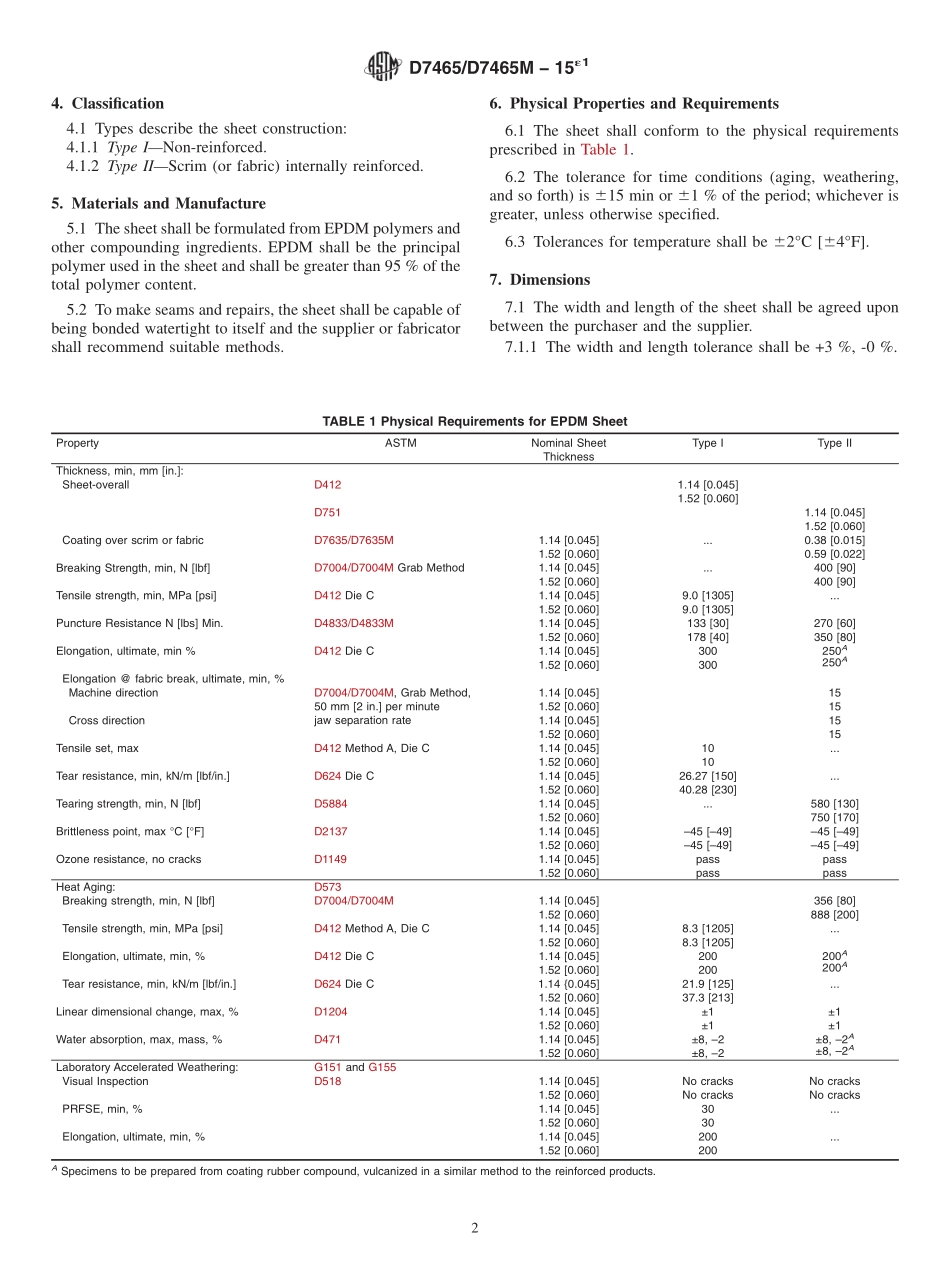

Designation:D7465/D7465M−15´1StandardSpecificationforEthylenePropyleneDieneTerpolymer(EPDM)SheetUsedInGeomembraneApplications1ThisstandardisissuedunderthefixeddesignationD7465/D7465M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ε1NOTE—Section9waseditoriallycorrectedinJuly2015.1.Scope1.1Thisspecificationcoversflexiblesheetmadefromethylenepropylenedieneterpolymer(EPDM)geomembraneintendedforuseingeotechnicalandgeoenvironmentalappli-cations.Thetestsandpropertylimitsusedtocharacterizethesheetarevaluestoensureminimumqualityfortheintendeduse.Thevulcanizedrubbersheetmaybenon-reinforced,fabricorscrimreinforced.1.2Inplacegeomembranedesigncriteria,suchasfieldseamingstrength,andmaterialcompatibility,amongothers,arefactorsthatmustbeconsideredbutarebeyondthescopeofthisspecification.1.3ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D412TestMethodsforVulcanizedRubberandThermoplas-ticElastomers—TensionD471TestMethodforRubberProperty—EffectofLiquidsD518TestMethodforRubberDeterioration—SurfaceCracking(Withdrawn2007)3D573TestMethodforRubber—DeteriorationinanAirOvenD624TestMethodforTearStrengthofConventionalVul-canizedRubberandThermoplasticElastomersD751TestMethodsforCoatedFabricsD1149TestMethodsforRubberDeterioration—CrackinginanOzoneControlledEnvironmentD1204TestMethodforLinea...