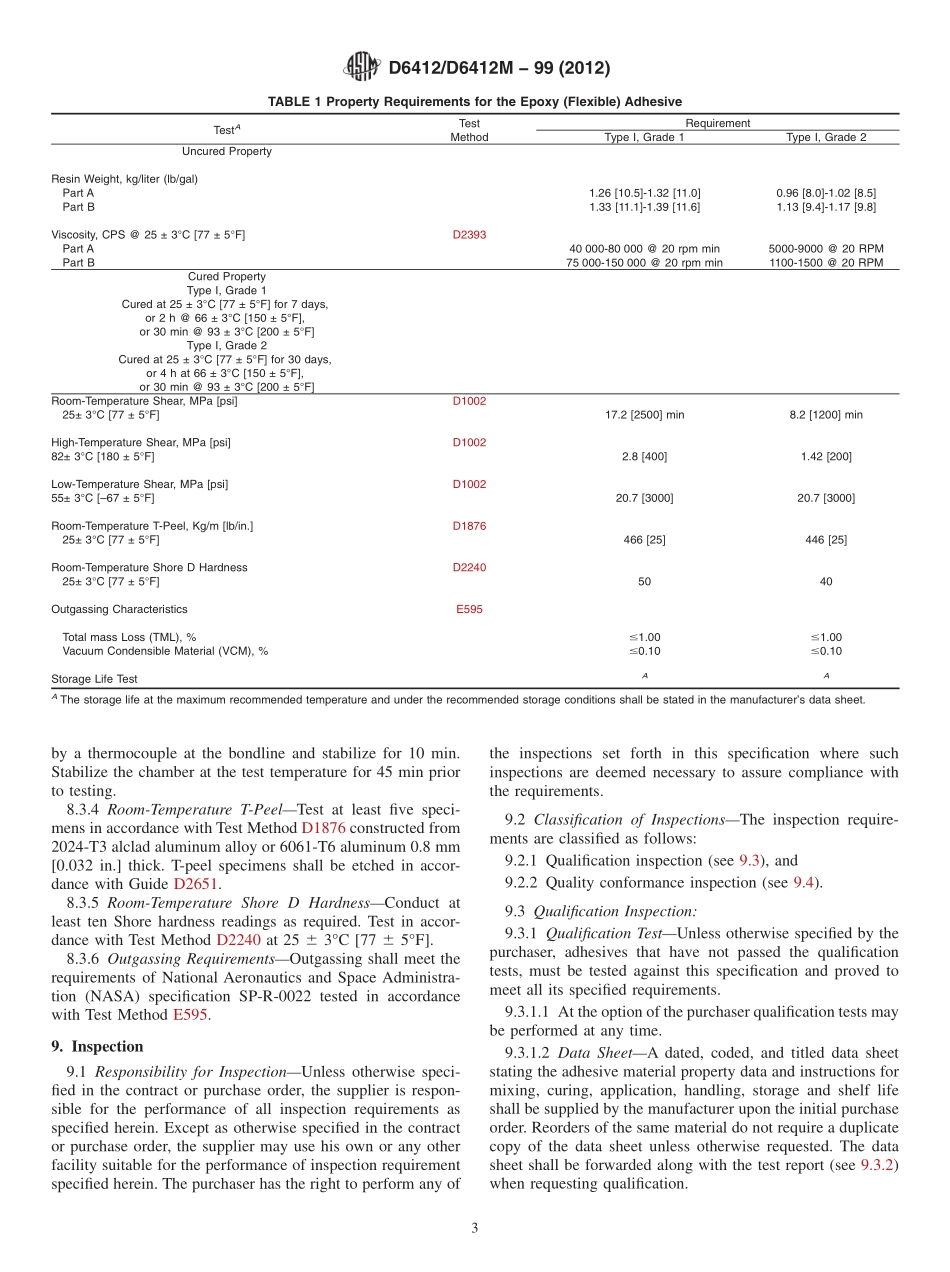

Designation:D6412/D6412M−99(Reapproved2012)StandardSpecificationForEpoxy(Flexible)AdhesiveForBondingMetallicAndNonmetallicMaterials1ThisstandardisissuedunderthefixeddesignationD6412/D6412M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thespecificationcoversatwo-partmodifiedepoxypasteadhesiveforbondingmetallicandnonmetallicmaterials.Theadhesiveshouldbesuitableforformingbondsthatcanwithstandenvironmentalexposuretotemperaturesfrom–184to82°C(–300to180°F)whenexposedtoanexpectedcombinationofstress,temperature,andrelativehumiditytobeencounteredinservice.NOTE1—WhencoordinatedthroughtheDepartmentofDefense(DoD)andtheNationalAeronauticsandSpaceAdministration(NASA),thispracticewillbeadirectreplacementofMIL-A-82720(OS),MIS-26872,andMSFC-SPEC-2037.1.2ThevaluesstatedinSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Withinthetext,theinch-poundunitsareshowninbrackets.Thevaluesstatedineachsystemarenotexactequivalents;therefore,eachsystemmustbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnonconformancewiththisspecification.1.3Thefollowingprecautionarystatementpertainstothetestmethodportiononly,Section8,ofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A109/A109MSpecificationforSteel,Strip,Carbon(0.25MaximumPercent),Cold-RolledA167SpecificationforStainlessandHeat-ResistingChromium-NickelSteelPlate,Sheet,andStripB209SpecificationforAluminumandAluminum-AlloySheetandPlateD907TerminologyofAdhesivesD1002TestMethodforApparentShearStrengthofSingle-Lap-JointAdhesivelyBondedMetalSpecimensb...