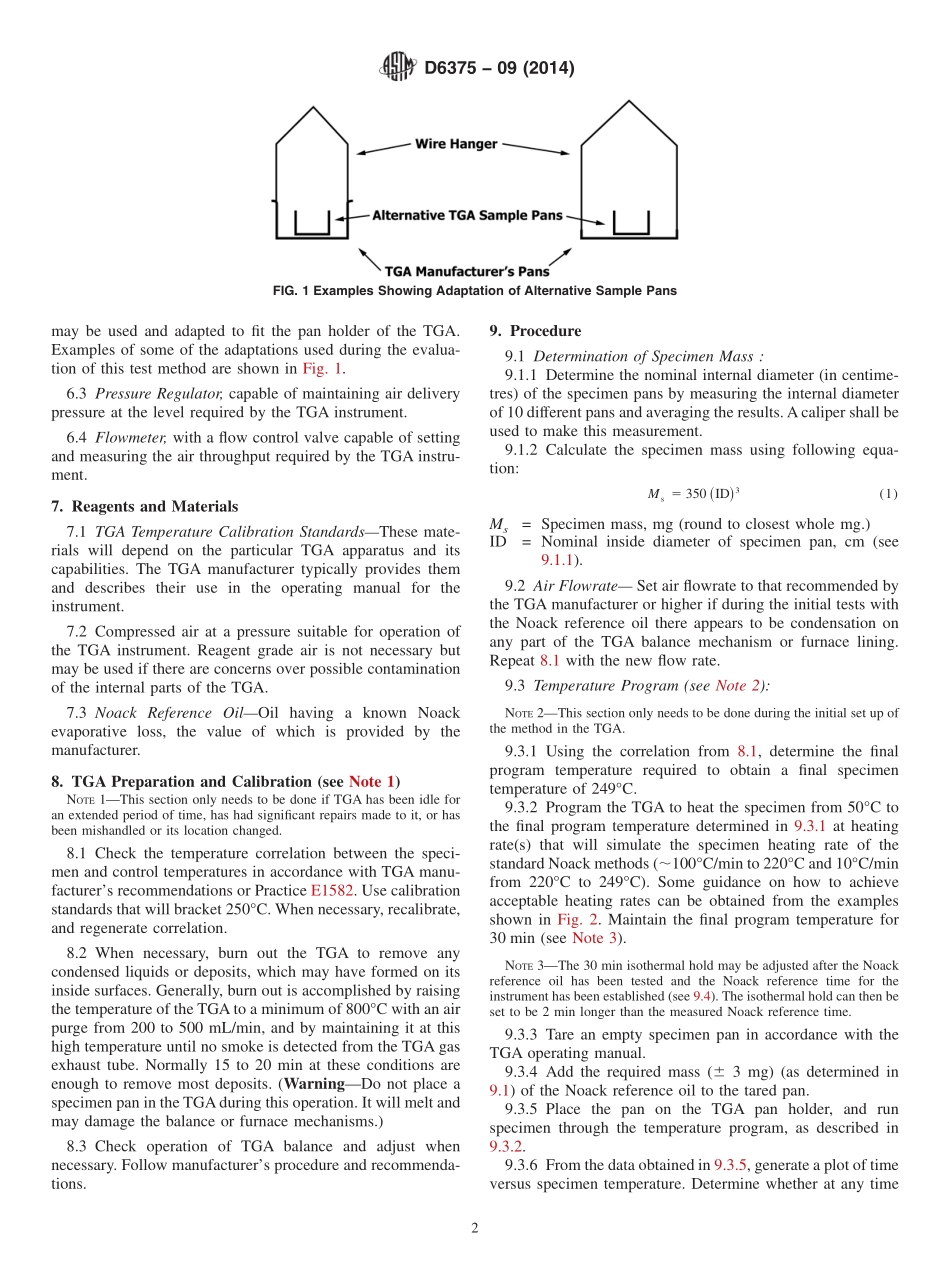

Designation:D6375−09(Reapproved2014)StandardTestMethodforEvaporationLossofLubricatingOilsbyThermogravimetricAnalyzer(TGA)NoackMethod1ThisstandardisissuedunderthefixeddesignationD6375;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThistestmethodcoverstheprocedurefordeterminingtheNoackevaporationlossoflubricatingoilsusingathermo-gravimetricanalyzertest(TGA).ThetestmethodisapplicabletobasestocksandfullyformulatedlubricantoilshavingaNoackevaporativelossrangingfrom0to30mass%.Thisprocedurerequiresmuchsmallerspecimens,andisfasterwhenmultiplesamplesaresequentiallyanalyzed,andsaferthanthestandardNoackmethodusingWood’smetal.1.2TheevaporativelossdeterminedbythistestmethodisthesameasthatdeterminedusingthestandardNoacktestmethods.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D5800TestMethodforEvaporationLossofLubricatingOilsbytheNoackMethodD6299PracticeforApplyingStatisticalQualityAssuranceandControlChartingTechniquestoEvaluateAnalyticalMeasurementSystemPerformanceD6792PracticeforQualitySysteminPetroleumProductsandLubricantsTestingLaboratoriesE1582PracticeforCalibrationofTemperatureScaleforThermogravimetry3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1Noackreferenceoil—theoilprovidedbyNoackequip-mentmanufacturerstocheckproperoperationoftheNoackevaporationtester.3.1.2Noackreferencetime—thetime(inminutes)requiredfortheNoackreferenceoiltoreachitsknownNoackevapo-rativelossundertheconditionsusedinthistestmethod.3....