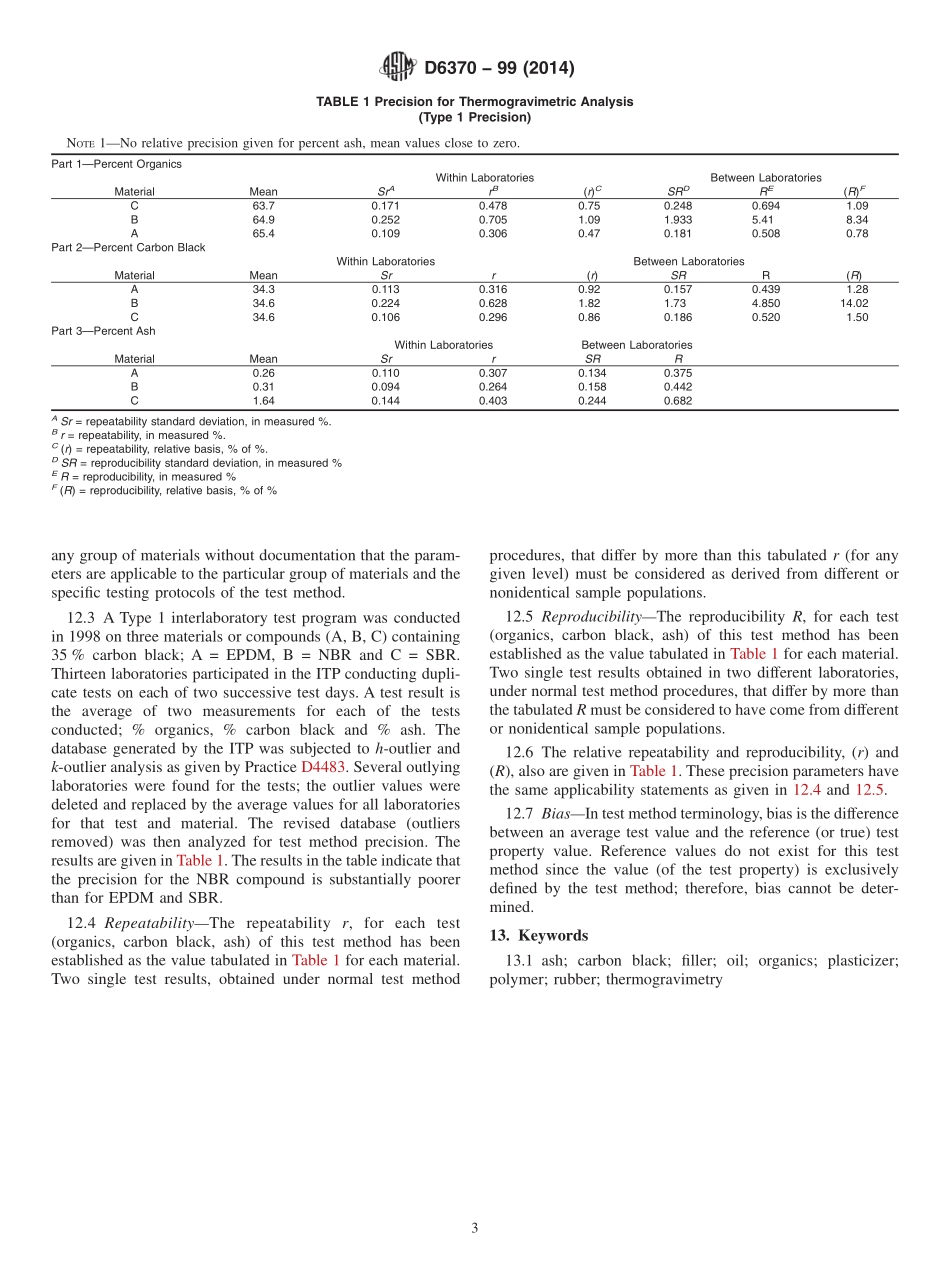

Designation:D6370−99(Reapproved2014)StandardTestMethodforRubber—CompositionalAnalysisbyThermogravimetry(TGA)1ThisstandardisissuedunderthefixeddesignationD6370;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodprovidesathermogravimetric(TGA)techniquetodeterminetheamountsoforganics(oil,polymer),carbonblackandash(filler)inarubbercompound.1.2Theamountofplasticizer/oilmaybedeterminedsepa-ratelyusingTestMethodD297.1.3Thistestmethodutilizespreviouslycalibrated,manualorcomputerassistedTGAinstrumentation.1.4ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D297TestMethodsforRubberProducts—ChemicalAnaly-sisD1566TerminologyRelatingtoRubberD4483PracticeforEvaluatingPrecisionforTestMethodStandardsintheRubberandCarbonBlackManufacturingIndustriesD6085PracticeforSamplinginRubberTesting—TerminologyandBasicConceptsE473TerminologyRelatingtoThermalAnalysisandRhe-ologyE1953PracticeforDescriptionofThermalAnalysisandRheologyApparatus3.Terminology3.1Definitions:3.1.1ThedefinitionsrelatingtorubberappearinginTermi-nologyD1566shallbeconsideredapplicabletothistestmethod.3.1.2TheterminologyrelatingtosamplingappearinginPracticeD6085shallbeconsideredapplicabletothistestmethod.3.1.3ThedefinitionsforthermalanalysisappearinginTerminologyE473shallbeconsideredapplicabletothistestmethod.3.1.4Thedescriptionofthermalanalysisequipmentappear-inginPracticeE1953shallbeconsideredapplicabletothistestmethod.3.2DefinitionsofTermsSpecifictoThisStandard:3...