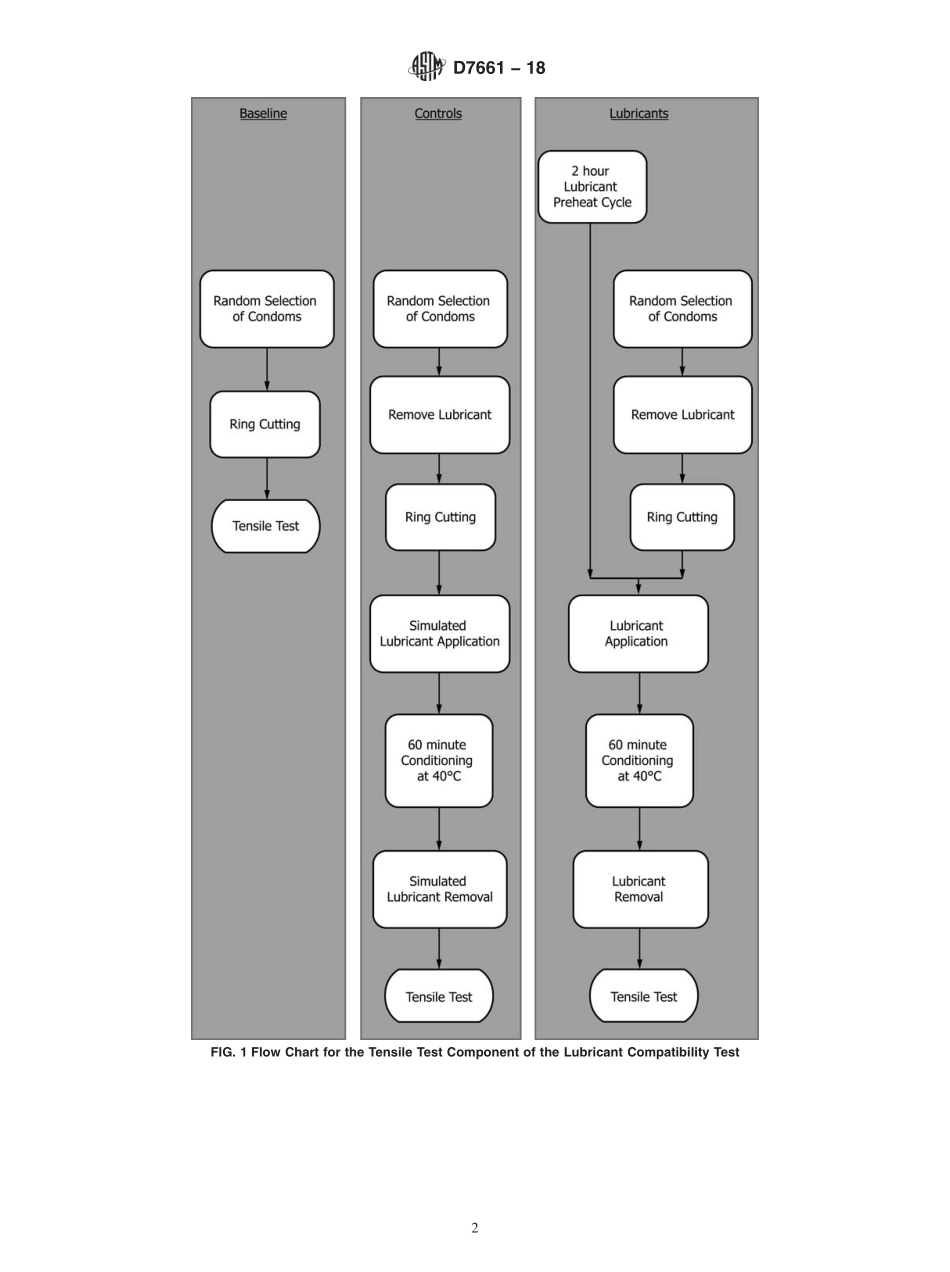

Designation:D7661−18StandardTestMethodforDeterminingCompatibilityofPersonalLubricantswithNaturalRubberLatexCondoms1ThisstandardisissuedunderthefixeddesignationD7661;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversproceduresusedtodetectashiftinphysicalpropertiesofnaturalrubberlatex(NRL)condomsafterimmersioninapersonallubricant.“Personallubricants”arelubricantssuchasliquidsorgelsthatareappliedbytheconsumeratthetimeofcondomuse.1.2Thistestmethoddoesnotattempttoaddresscompat-ibilityoflubricantsappliedtoacondomatthetimeofmanufacture(“manufacturerlubricants”).Itshallbethere-sponsibilityofthecondommanufacturertoverifythelong-termstability(shelflife)ofanymanufacturerlubricantthatispackagedwithintheindividualcondomwrapper.Otherregu-latoryrequirementsmayapply.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D3492SpecificationforRubberContraceptives(MaleCon-doms)E177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.SummaryofTestMethod3.1Thistestmethodmeasuresthechangeintensileandairburstproperties,specificallyforceatbreak...