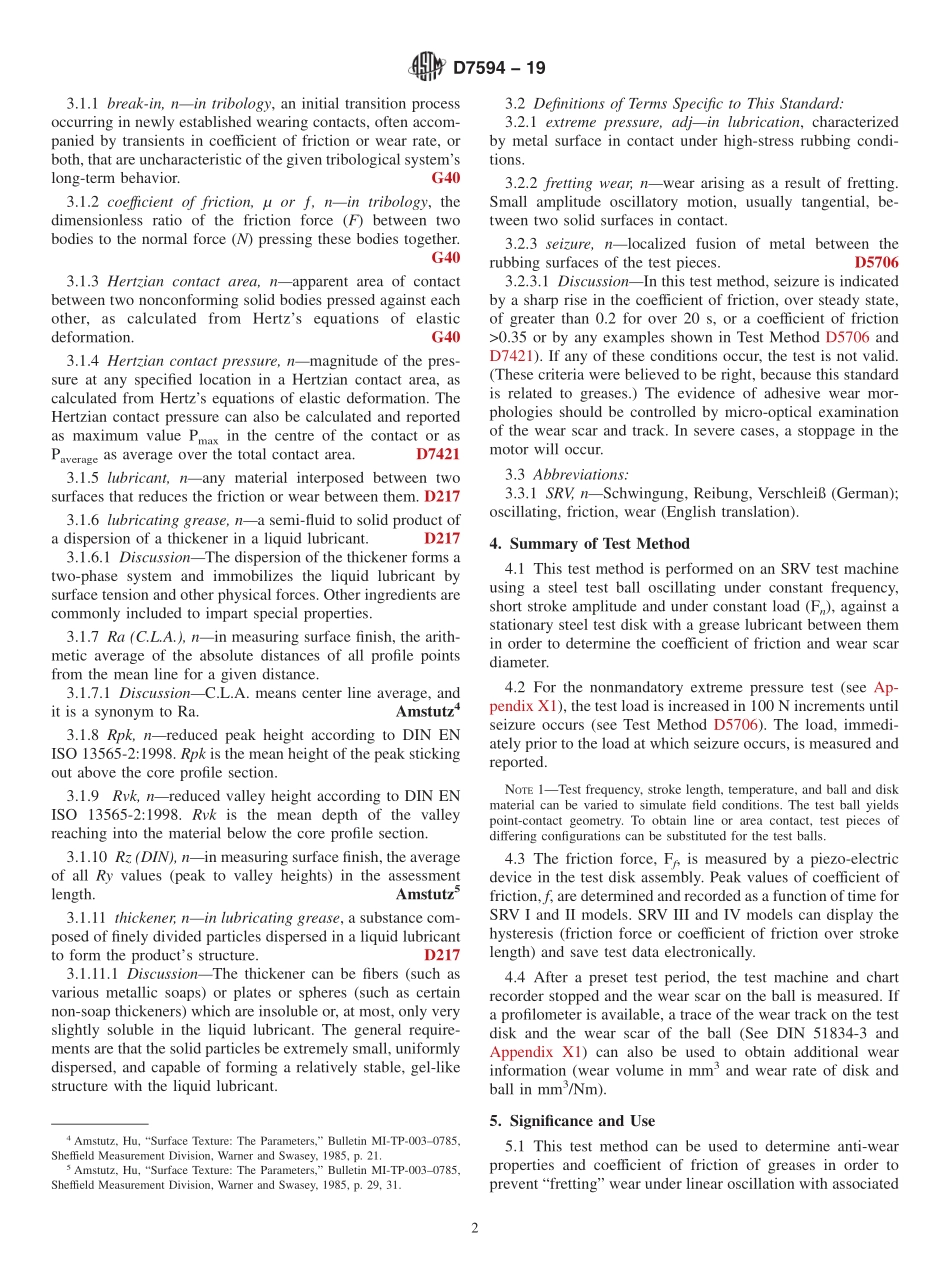

Designation:D7594−19StandardTestMethodforDeterminingFrettingWearResistanceofLubricatingGreasesUnderHighHertzianContactPressuresUsingaHigh-Frequency,Linear-Oscillation(SRV)TestMachine1ThisstandardisissuedunderthefixeddesignationD7594;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodcoversaprocedurefordeterminingthelubricatingactionofgreasesinordertoprevent“fretting”wearunderlinearoscillationwithassociatedlowstrokesandhighHertziancontactpressuresunderhigh-frequencylinear-oscillationmotionusingtheSRVtestmachine.Byperformingadditional,nonmandatoryextreme-pressuretestsinaccordancewithTestMethodD5706,thetestgreaseshouldbeshowntobeabletowithstandaHertziancontactpressureofatleast2200MPawithoutadhesivefailure.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2A295/A295MSpecificationforHigh-CarbonAnti-FrictionBearingSteelD217TestMethodsforConePenetrationofLubricatingGreaseD235SpecificationforMineralSpirits(PetroleumSpirits)(HydrocarbonDryCleaningSolvent)D4175TerminologyRelatingtoPetroleumProducts,LiquidFuels,andLubricantsD5706TestMethodforDeterminingExtremePressurePropertiesofLubricatingGreasesUsingaHigh-Frequency,Linea...