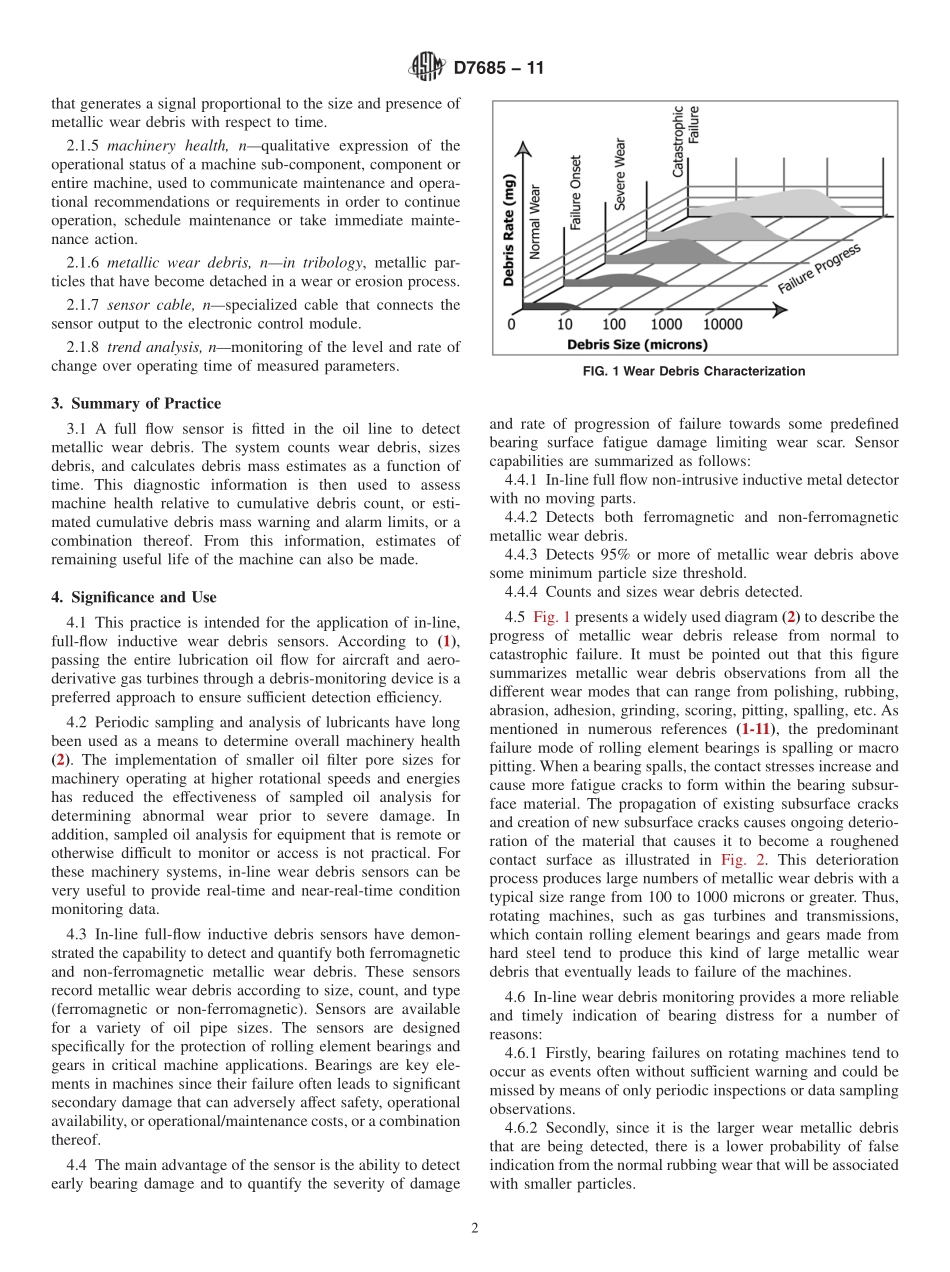

Designation:D7685−11StandardPracticeforIn-Line,FullFlow,InductiveSensorforFerromagneticandNon-ferromagneticWearDebrisDeterminationandDiagnosticsforAero-DerivativeandAircraftGasTurbineEngineBearings1ThisstandardisissuedunderthefixeddesignationD7685;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.INTRODUCTIONIn-lineweardebrissensorshavebeeninoperationsincetheearly1990s.Therearenowthousandsofthesedevicesoperatinginawidevarietyofmachineryapplicationsaccruingmillionsofoperationalhours.Weardebrissensorsprovideearlywarningfortheabnormalconditionsthatleadtofailure.Improvedmachinereliabilityispossibleduetotheenhancedsensordatagranularity,whichprovidesbetterdiagnosticsandprognosticsoftribologicalproblemsfromtheinitiatingeventthroughfailure.1.Scope1.1Thispracticecoverstheminimumrequirementsforanin-line,non-intrusive,through-flowoildebrismonitoringsys-temthatmonitorsferromagneticandnon-ferromagneticmetal-licweardebrisfrombothindustrialaero-derivativeandaircraftgasturbineenginebearings.Gasturbineenginesarerotatingmachinesfittedwithhigh-speedballandrollerbearingsthatcanbethecauseoffailuremodeswithhighsecondarydamagepotential.(1)21.2Metallicweardebrisconsideredinthispracticerangeinsizefrom120µm(micron)andgreater.Metallicweardebrisover1000µmaresizedasover1000µm.1.3Thispracticeissuitableforusewiththefollowinglubricants:polyolesters,phosphateesters,petroleumindustrialgearoilsandpetroleumcrankcaseoils.1.4Thispracticeisformetallicweardebrisdetection,notcleanliness.1.5ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesgiveninparenthesesareprovidedforinformationonly.1.6Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bil...