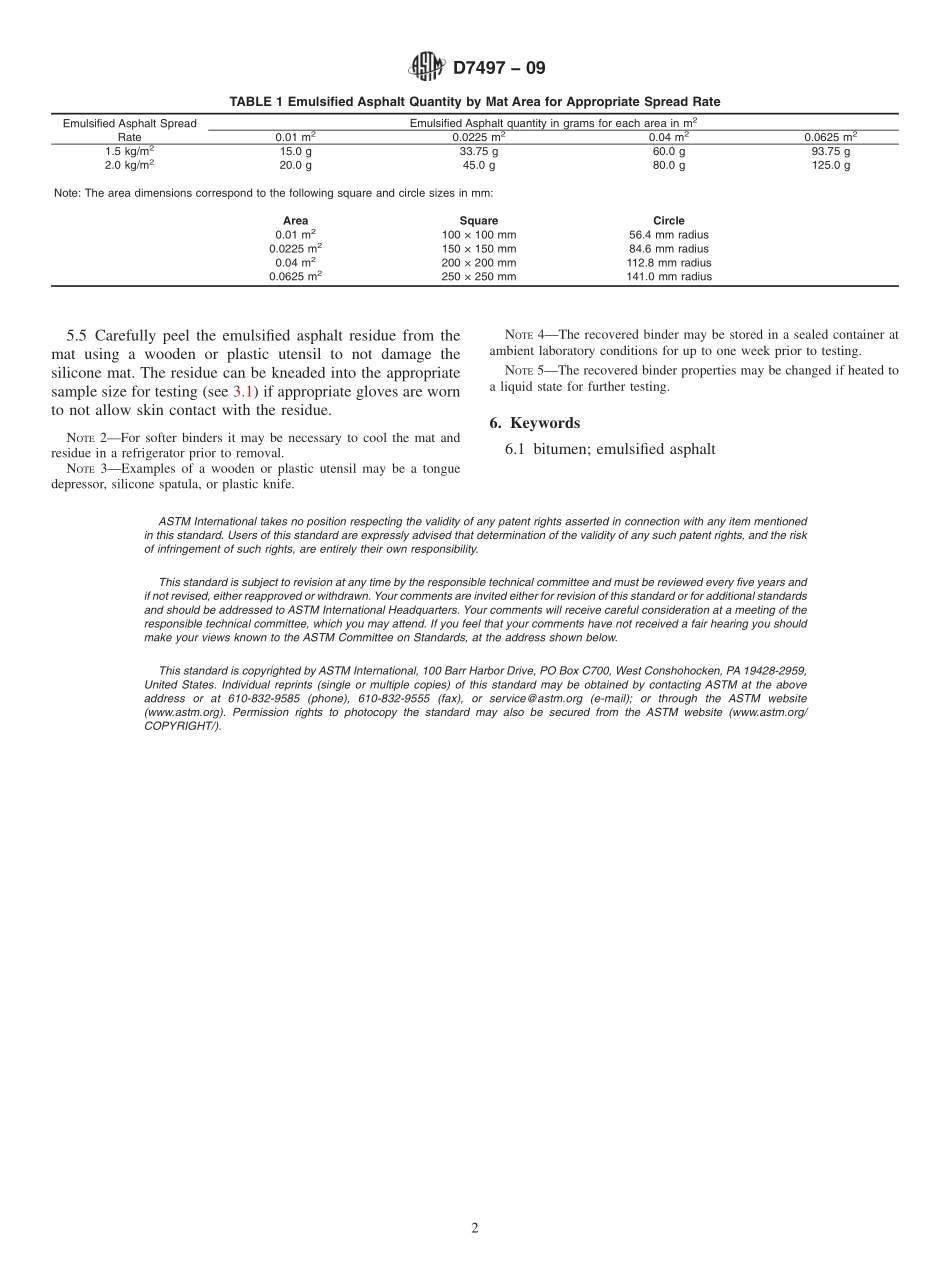

Designation:D7497−09StandardPracticeforRecoveringResiduefromEmulsifiedAsphaltUsingLowTemperatureEvaporativeTechnique1ThisstandardisissuedunderthefixeddesignationD7497;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThispracticecoversamethodforrecoveringtheresiduefromemulsifiedasphaltssuchasthosespecifiedinD977andD2397usingalowtemperatureevaporativetechniquethatissimilartopavementconditions.Therecoveredresiduecanbeusedforfurthertestingasrequired.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D977SpecificationforEmulsifiedAsphaltD2397SpecificationforCationicEmulsifiedAsphaltD6934TestMethodforResiduebyEvaporationofEmulsi-fiedAsphaltD6997TestMethodforDistillationofEmulsifiedAsphalt2.2OtherStandard:NFEN13074RecoveryofBinderfromBitumenEmulsionsbyEvaporation33.SignificanceandUse3.1Theproceduredescribedinthispracticeisusedtoobtainaresiduefromanemulsifiedasphaltthatmaybeusedforfurthertestingindevicessuchasadynamicshearrheom-eter.Thelowerevaporativetemperaturesofthisprocedureprovideconditionsthatareveryclosetothatofapplicationtechniquesforthesematerials.ThispracticecouldbeusedinplaceofrecoverytechniquessuchasthoseofD6934andD6997,whenthetemperaturesusedinthosestandardswouldnegativelyaffecttheresidue.4.ReagentsandMaterials4.1SiliconeMat—ThematusedcanbesimilartothatspecifiedinNFEN13074oranymatthatwillallowanemulsifiedasphaltspreadrateof1.5–2.0kg/m2.Thematmayhavealiptocontaintheemulsifiedasphalttotheappropriatearea.NOTE1—Asil...