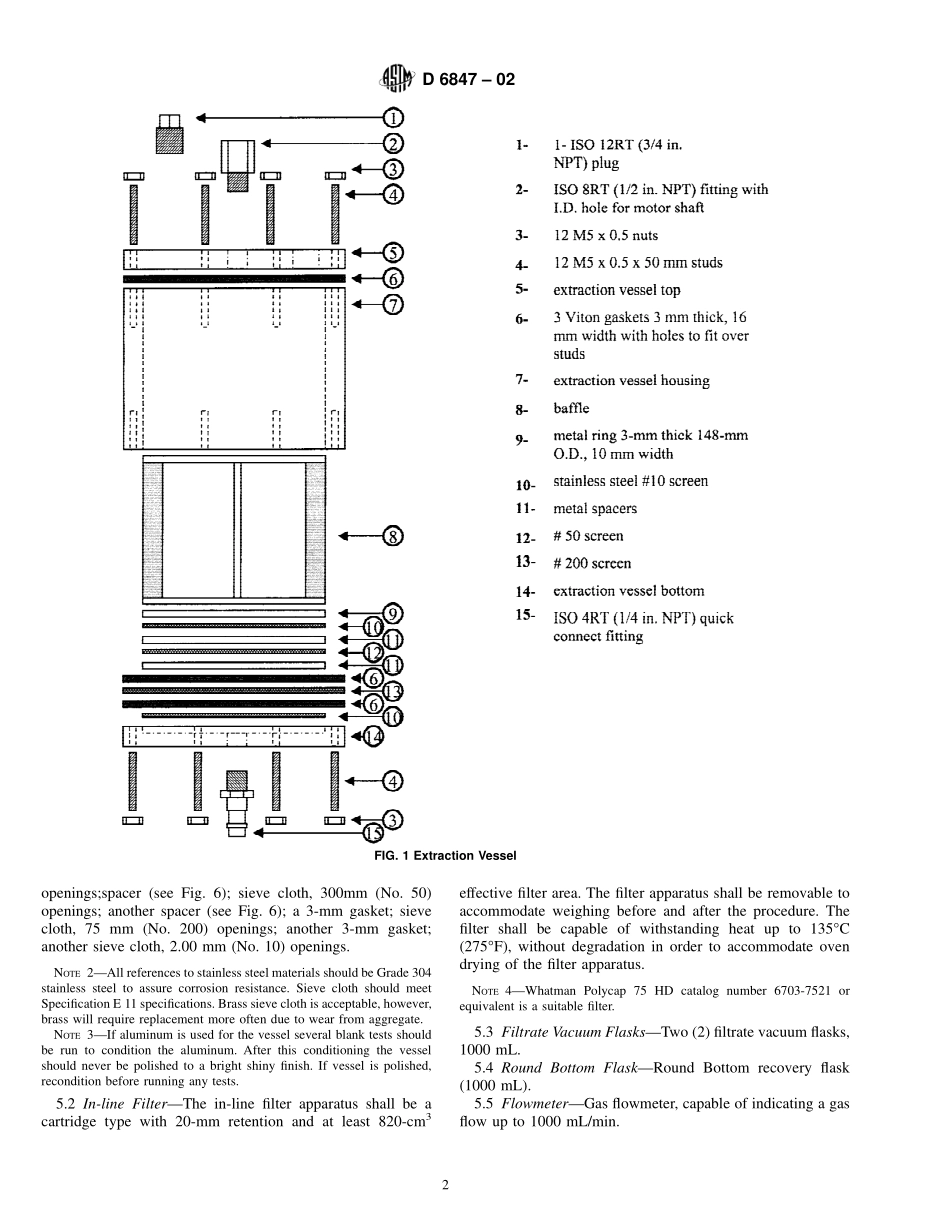

Designation:D6847–02StandardTestMethodforQuantitativeExtractionandRecoveryofAsphaltBinderfromAsphaltMixtures1ThisprovisionalstandardisissuedunderthefixeddesignationD6847;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoption.1.Scope1.1Thistestmethodcoversaprocedurefortheextractionandrecoveryofasphaltbinderfromasphaltmixtures—bothHMA(hotmixasphalt)andRAP(reclaimed/recycledasphaltpavement)—havingaminimaleffectonthephysicalpropertiesoftheasphaltbinderrecovered.Itisprimarilyintendedforusewhenthephysicalpropertiesoftherecoveredasphaltaretobedetermined.ItcanalsobeusedtodeterminethequantityofasphaltbinderintheHMAorRAP.Recoveredaggregatemaybeusedforsieveanalysis.ThismayalsobeaccomplishedthroughTestMethodsD2172.1.2ThevaluesstatedinSIunitsareregardedasthestandard.Valuesinparenthesesareforinformationaluse.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ItissuggestedthatagencyandpersonnelperformingthistestmeettherequirementsofSpecificationD3666.2.ReferencedDocuments2.1ASTMStandards:D75PracticeforSamplingAggregates2D979PracticeforSamplingBituminousPavingMixtures2D1461TestMethodforMoistureorVolatileDistillatesinBituminousPavingMixtures2D2172TestMethodsforQuantitativeExtractionofBitu-menFromBituminousPavingMixtures2D2939TestMethodsforEmulsifiedBitumensUsedasProtectiveCoatings3D3666SpecificationforMinimumRequirementsforAgen-ciesTestingandInspectingRoadandPavingMaterials2D4753SpecificationforEvaluating,Selecting,andSpeci-fyingBalancesandScalesforUseinTestingSoil,Rock,andRelatedConstructionMaterials4D5361PracticeforSamplingCompactedBituminousMix-turesforLaboratoryTesting2D5444TestMethodforMechanicalSizeAnalysisofEx-tractedAggregate2E11SpecificationforWireClothandSievesforTestingPurposes53.SummaryofTestMethod3.1Theasphaltmixtureisrepeatedlywashedandfilteredwi...