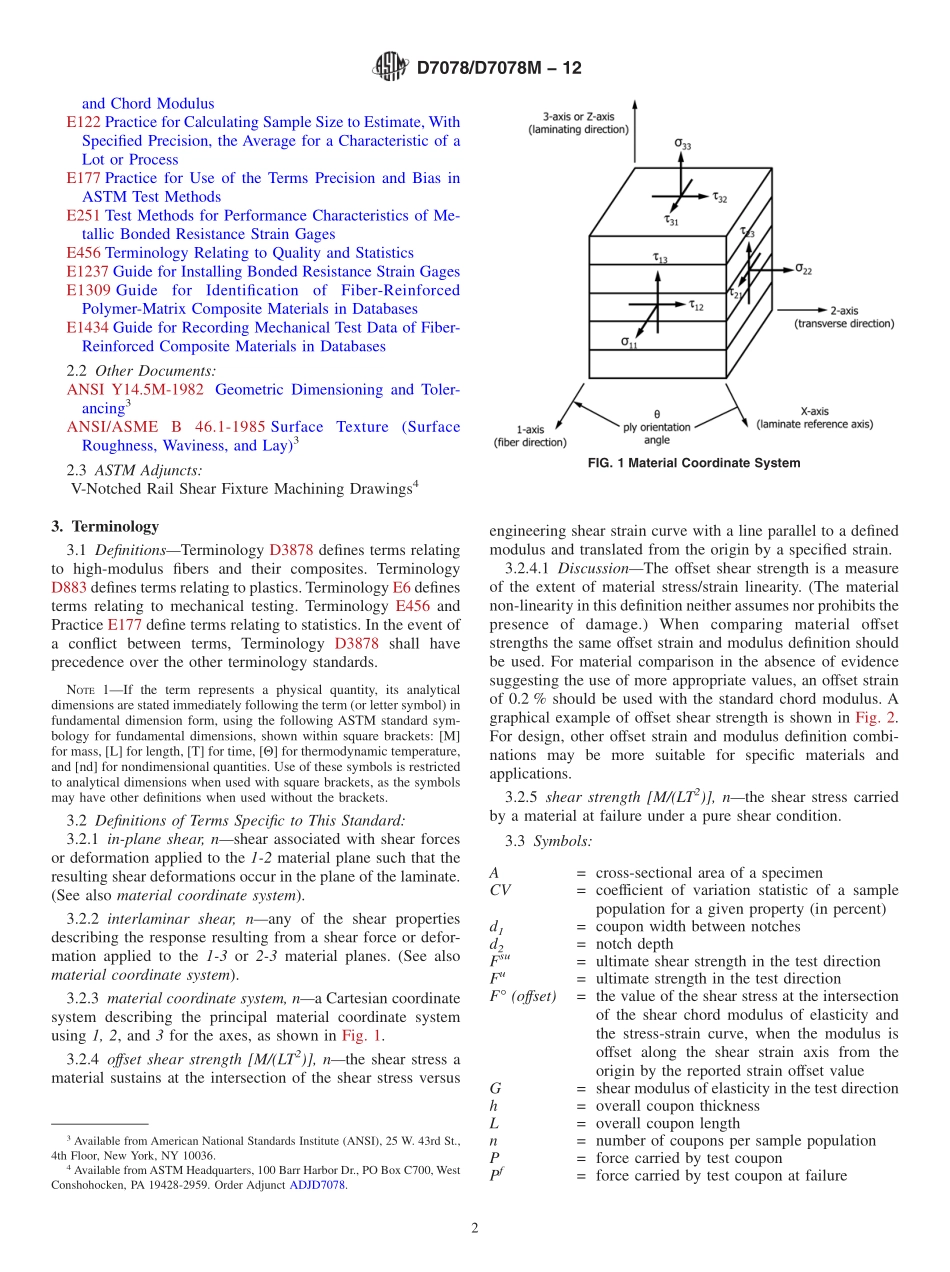

Designation:D7078/D7078M−12StandardTestMethodforShearPropertiesofCompositeMaterialsbyV-NotchedRailShearMethod1ThisstandardisissuedunderthefixeddesignationD7078/D7078M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationoftheshearpropertiesofhigh-modulusfiber-reinforcedcompositemateri-alsbyclampingtheendsofaV-notchedspecimenbetweentwopairsofloadingrails.Whenloadedintension,therailsintroduceshearforcesintothespecimenthroughthespecimenfaces.Incomparison,thespecimenofTestMethodD5379/D5379Misloadedthroughitstopandbottomedges.Faceloadingallowshighershearforcestobeappliedtothespecimen,ifrequired.Additionally,thepresenttestmethodutilizesaspecimenwithalargergagesectionthantheV-notchedspecimenofTestMethodD5379/D5379M.Inbothtestmethods,theuseofaV-notchedspecimenincreasesthegagesectionshearstressesinrelationtotheshearstressesinthevicinityofthegrips,thuslocalizingthefailurewithinthegagesectionwhilecausingtheshearstressdistributiontobemoreuniformthaninaspecimenwithoutnotches.Incomparison,TestMethodD4255/D4255Mutilizesanun-notchedspecimenclampedbetweentwopairsofloadingrailsthatareloadedintension.AlsoincontrasttoTestMethodD4255/D4255M,thepresenttestmethodprovidesspecimengrippingwithouttheneedforholesinthespecimen.Thecompositematerialsarelimitedtocontinuous-fiberordiscontinuous-fiber-reinforcedcompositesinthefollowingma-terialforms:1.1.1Laminatescomposedonlyofunidirectionalfibrouslaminae,withthefiberdirectionorientedeitherparallelorperpendiculartothefixturerails.1.1.2Laminatesofbalancedandsymmetricconstruction,withthe0°directionorientedeitherparallelorperpendiculartothefixturerails.1.1.3Laminatescomposedofwoven,braided,orknittedfabricfilamentarylaminae.1.1.4Short-fiber-reinforcedcompositeswithamajorityofthefibersbeingrandomlydistri...