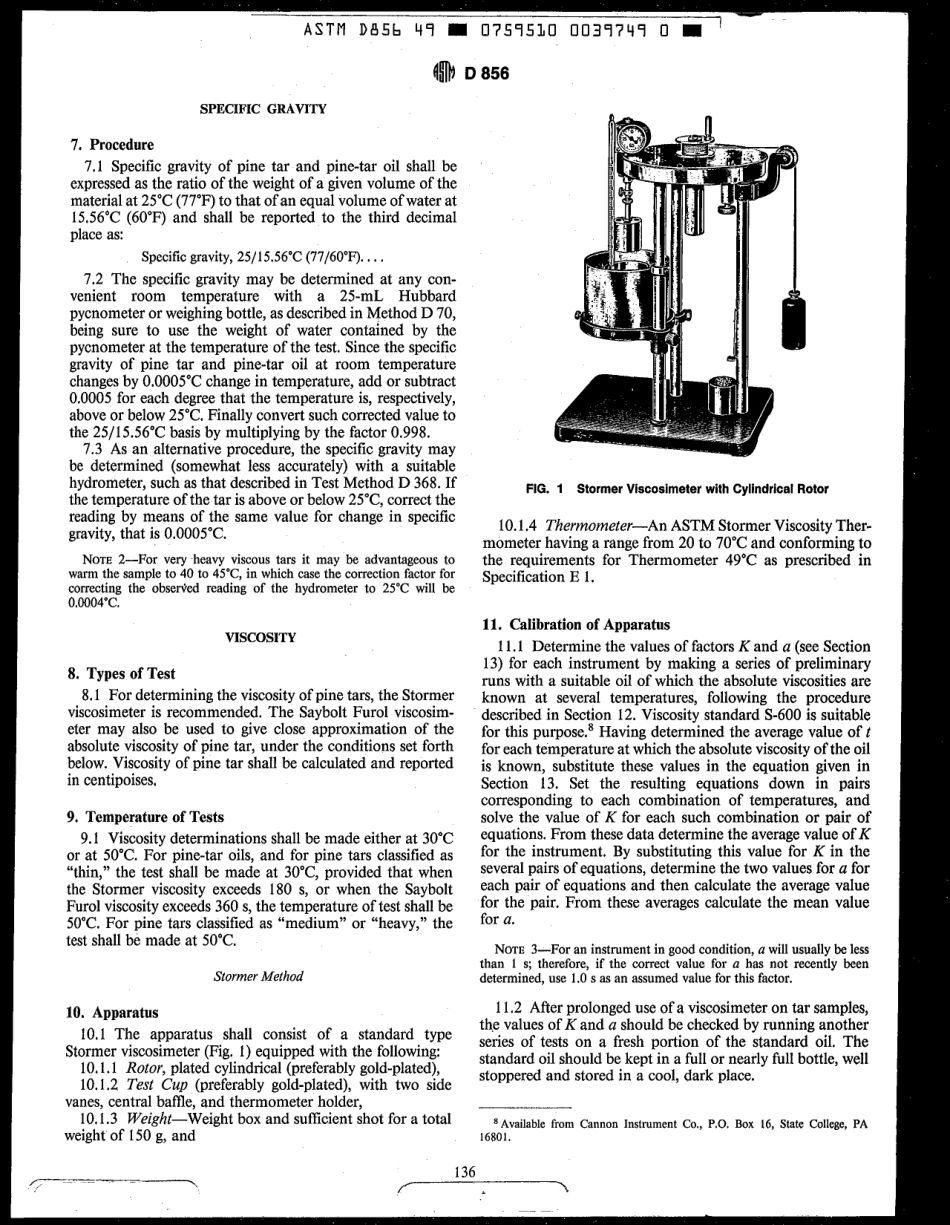

@))Designation:D856-49(Reapproved1987)StandardTestMethodsforSamplingandTestingPineTarsandPine-TarOils‘ThisstandardisissuedunderthefixeddesignationD856;thenumberimmediatelyfoliowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.ScopeI.1Thesetestmethodscoverproceduresforsamplingandtestingpinetars,bothkilnandretort,andpine-taroils,togetherwith‘compoundedtarproductsofnavalstoresorigin.1.2Thisstaiidardmayiiivolvehazardousmaterials,oper-ations,andeqiiipmeiit.TWstandarddoesriotpurporttoaddressallofthesafityproblemsassociatedwithitsuse.Itistherespoiisibilityoftheuserofthisstandardtoestablishappropriatesafelyandhealthpracticesanddeterminetheapplicabilityofregulatorylintitationspriortoirse.2.ReferencedDocuments2.1ASTMStandards:D20TestMethodforDistillationofRoadTars2D70TestMethodforSpecificGravityofSemi-SolidD88TestMethodforSayboltViscosity4D140MethodsofSampling3ituminousMaterials2D270MethodofSamplingPetroleumandPetroleumD368TestMethodforSpecificGravityofCreosoteandE€SpecificationforASTMThermometers7BituminousMaterials3Products5Oil-TypePreservatives‘3.Sampling3.1GeneralSamplingProcediire-ThematerialshallbesampledinaccordancewiththeapplicableportionsofMethodsD140andD270.3.2KilnPirieTarinBarrelsorDntrns-Thistypeoftarmaycontainmorethanthesmallpermissiblequantityofwaterusuallypresentundergoodproducingpractice.Thewatermaybeseparatedatthetop,butitisnotunusualtofinditsettledoutatthebottomofthecontainer,duetoahighconcentrationofdissolvedtaracids.(Ingoodpracticemostofthiswatershouldberemovedatthepointofproductionorpreparationforshipment.)Bymeansofa“thief’orarodatleast1fi(0.3m)longerthanthelengthordiameterofthecontainer,soastopermitittoextendtothebottomofthebarrelordrum(theusualtypeofcontainer)probethetarattopandbottom,withouttoomuchagitation,toascertainwhetherthereisanyappreciablequantityofwaterpre...