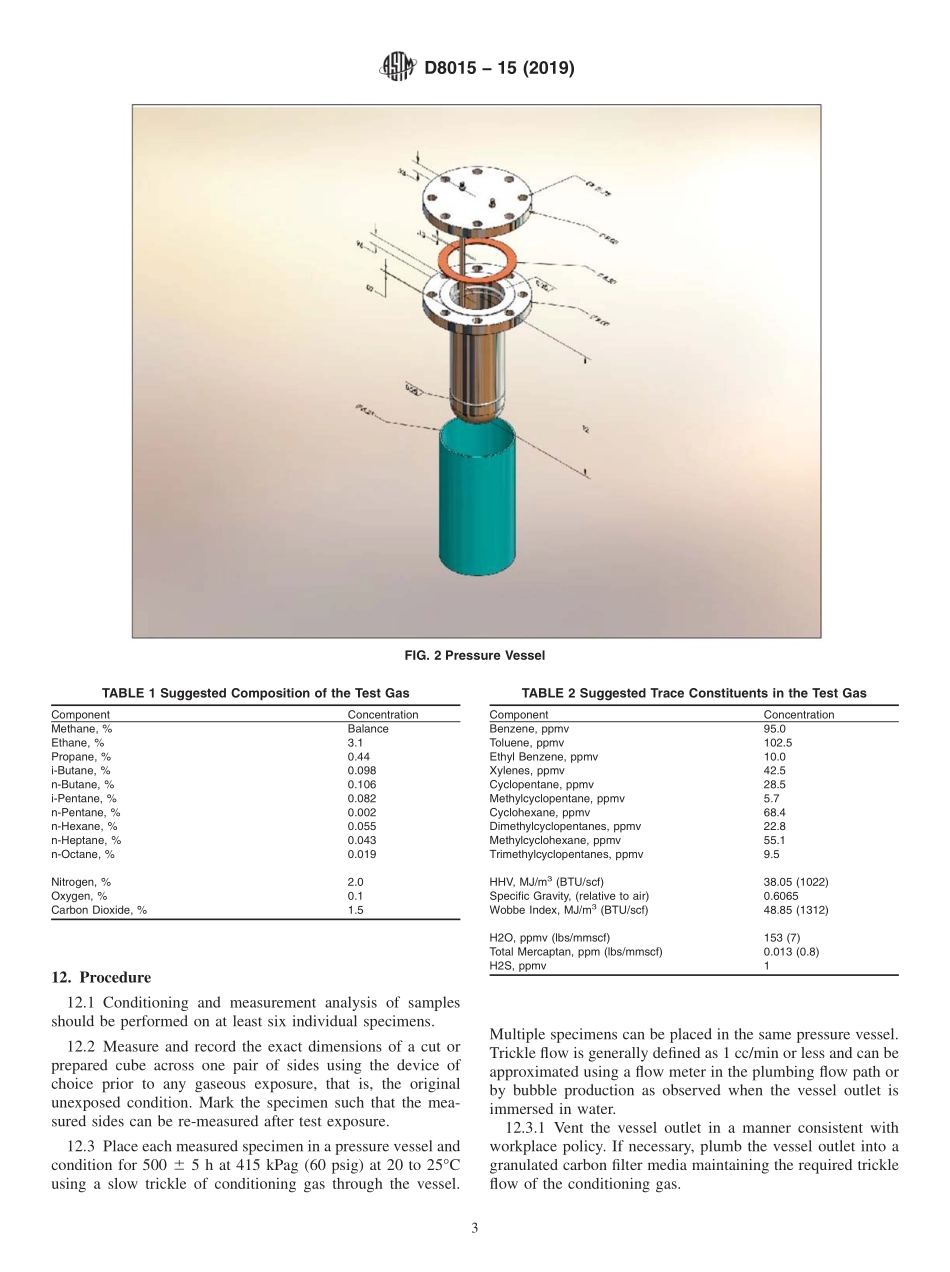

Designation:D8015−15(Reapproved2019)StandardTestMethodforDimensionalChangesofElastomerandRubberMaterialsDuetoExposuretoGaseousHydrocarbonEnvironments1ThisstandardisissuedunderthefixeddesignationD8015;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisstandardgivesthetestingproceduretodeterminethechangeindimensionsofspecimensofrubberorelasto-mericmaterials,orboth,resultingfromexposuretogaseoushydrocarbonenvironments.Thesizeofthespecimensissuchtofacilitatepreparationfromasmoldedcomponentconfigura-tionssuchasgasketsandseals.Whereagreedtobybothpartiesmoldedspecimensmaybeused.Dimensionalmeasurementsaremadepriortoandafterconditioninginaformulatedtestgas.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D1418PracticeforRubberandRubberLatices—NomenclatureD1566TerminologyRelatingtoRubber3.Terminology3.1Definitions—Fordefinitionsoftechnicaltermspertain-ingtorubberusedinthisspecification,seeTerminologyD1566.3.2Definitions—ThenomenclatureandabbreviationsusedfornaturalandsyntheticrubbersareinaccordancewithPracticeD1418.3.3Abbreviations:3.3.1Abbreviationsusedinthedescriptionofnaturalgascomposition:3.3.2mmscf—millionstandardcubicfoot3.3...