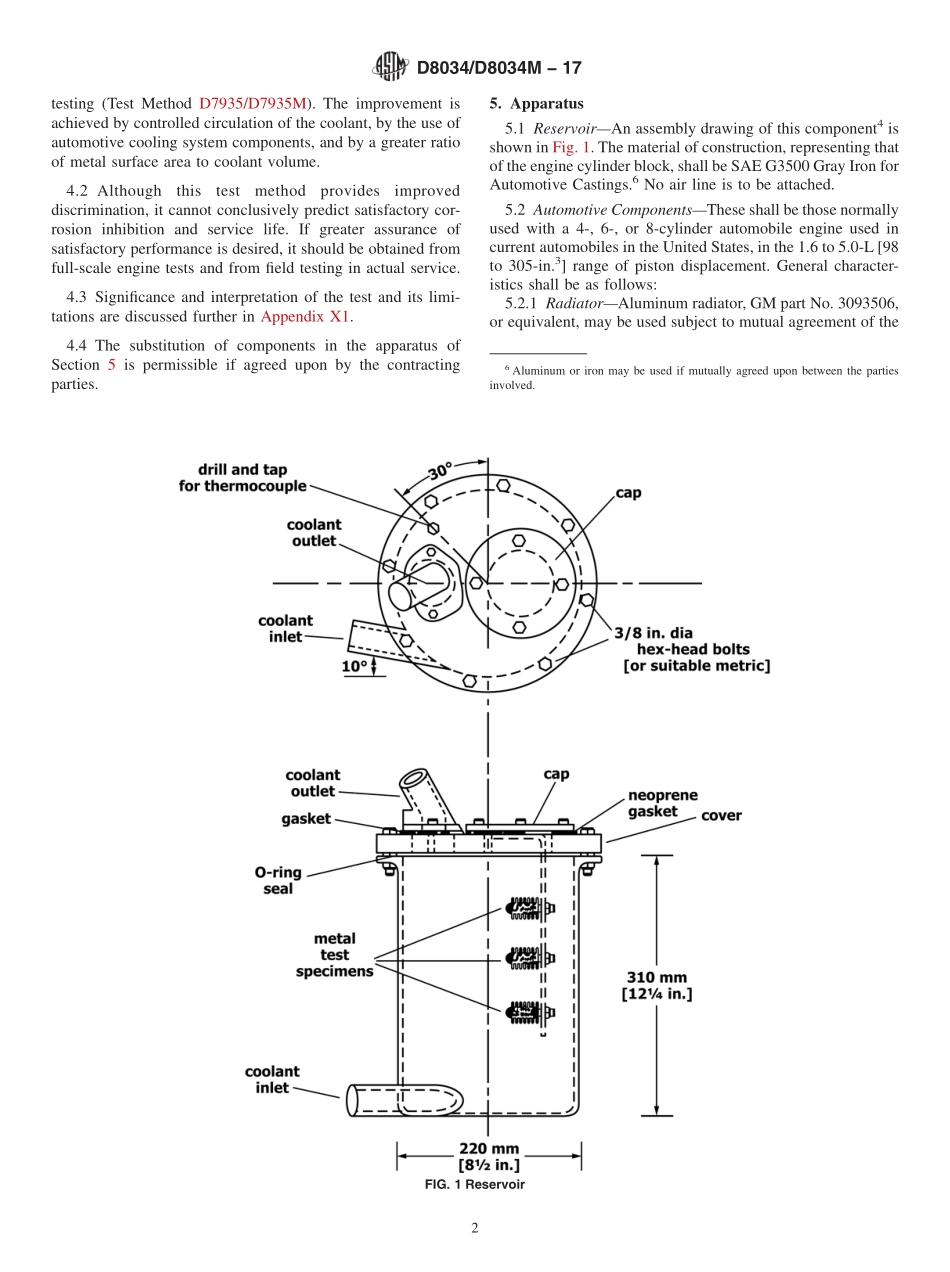

Designation:D8034/D8034M−17StandardTestMethodforSimulatedServiceCorrosionTestingofNon-AqueousEngineCoolants1ThisstandardisissuedunderthefixeddesignationD8034/D8034M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodevaluatestheeffectofacirculatingenginecoolantonmetaltestspecimensandautomotivecoolingsystemcomponentsundercontrolled,essentiallyisothermallaboratoryconditions.1.2Thistestmethodspecifiestestmaterial,coolingsystemcomponents,typeofcoolant,andcoolantflowconditionsthatareconsideredtypicalofcurrentautomotiveuse.1.3ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.SomevalueshaveonlySIunitsbecausetheinch-poundequivalentsarenotusedinpractice.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Specificprecau-tionarystatementsaregiveninSection6.1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D1121TestMethodforReserveAlkalinityofEngineCool-antsandAntirustsD1123TestMethodsforWaterinEngineCoolantConcen-tratebytheKarlFischerReagentMethodD1176PracticeforSamplingandPreparingAqueousSolu-tionsofEngineCoolantsorAntirustsforTestingPurposesD1193SpecificationforReagentWaterD1287T...