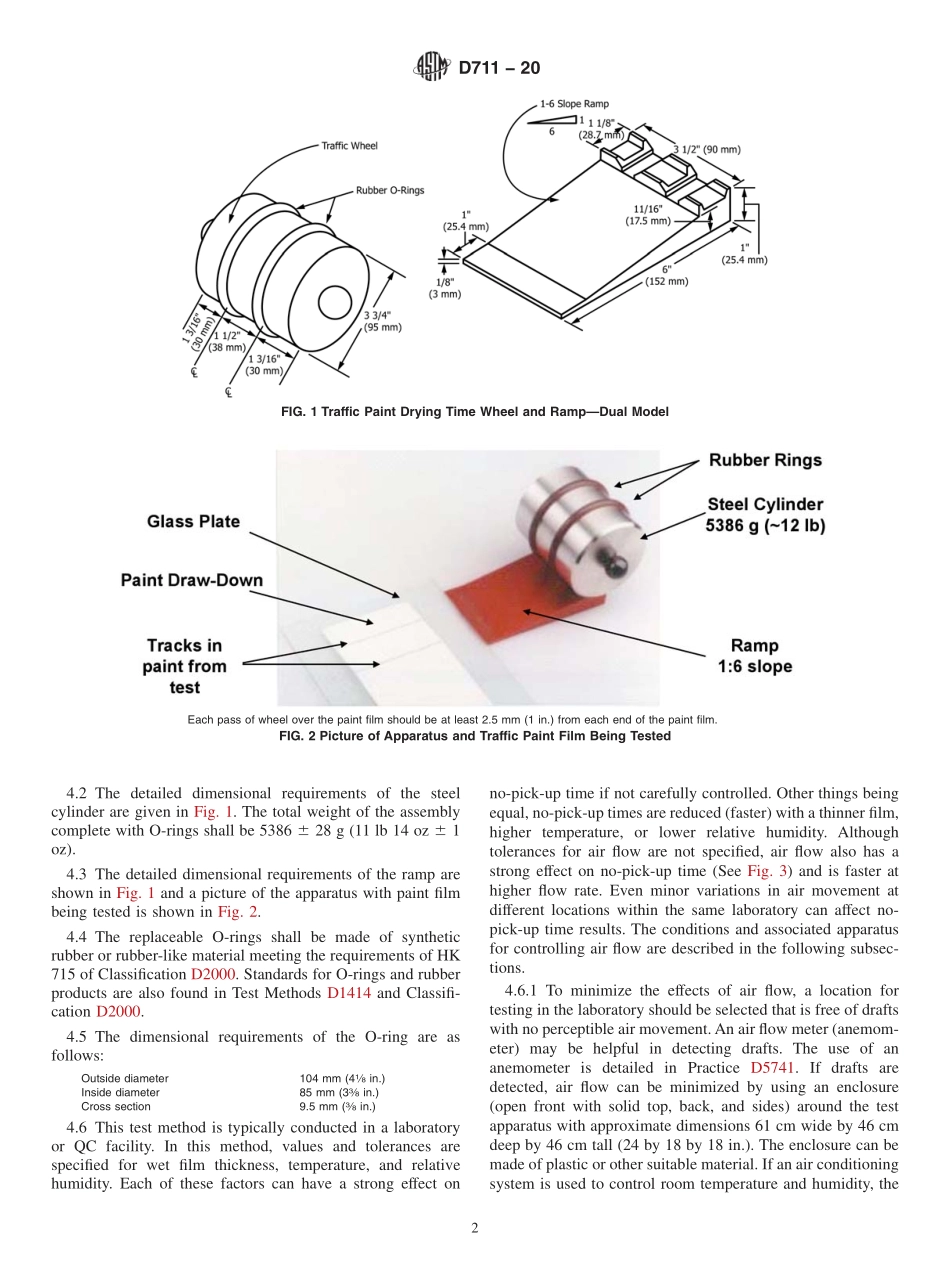

Designation:D711−20StandardTestMethodforNo-Pick-UpTimeofTrafficPaint1ThisstandardisissuedunderthefixeddesignationD711;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoversalaboratoryprocedurefordeterminingtheno-pick-uptimeofatrafficpaint.ThemethodusesawheelconsistingofametalcylinderwithrubberO-rings.Thewheelisrolleddownarampoverafreshlyappliedtrafficpaintfilmrepeatedlyuntilthereisnotransferofpainttotherubberrings.Theelapsedtimefrompaintfilmapplicationtopointofnopainttransferistheno-pick-uptime.Keyvariablestobecontrolledduringtestingarefilmthickness,temperature,humidity,andairflow.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D823PracticesforProducingFilmsofUniformThicknessofPaint,CoatingsandRelatedProductsonTestPanelsD1212TestMethodsforMeasurementofWetFilmThick-nessofOrganicCoatingsD1414TestMethodsforRubberO-RingsD2000ClassificationSystemforRubberProductsinAuto-motiveApplicationsD4414PracticeforMeasurementofWetFilmThicknessbyNotchGagesD5741PracticeforCharacterizingSurfaceWindUsingaWindVaneandRotatingAnemometer3.SignificanceandUse3.1Th...