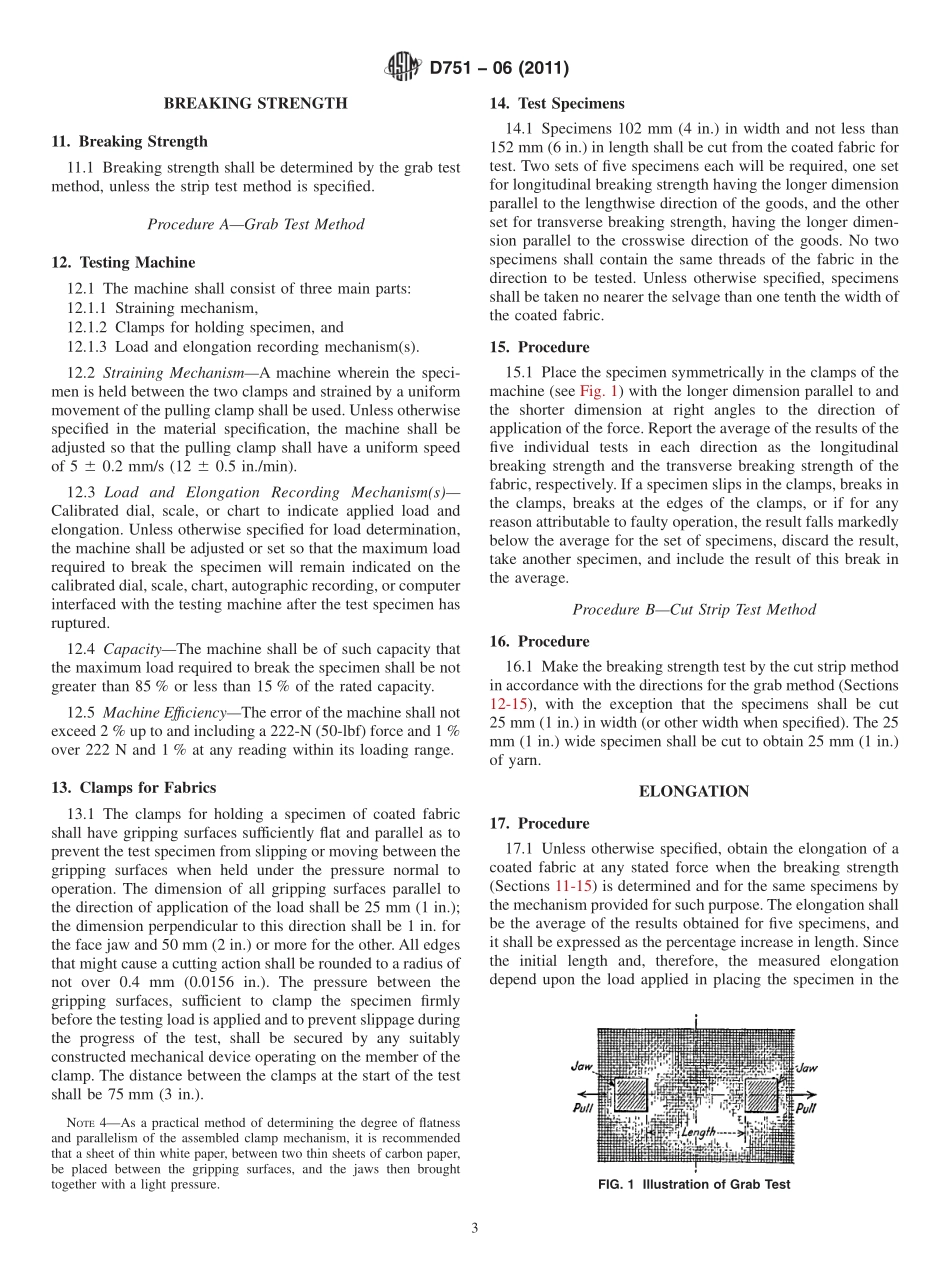

Designation:D751−06(Reapproved2011)StandardTestMethodsforCoatedFabrics1ThisstandardisissuedunderthefixeddesignationD751;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thesetestmethodscover,butarenotlimitedto,rubber-coatedfabrics,thatis,tarpaulins,rainwear,andsimilarproducts.1.2Thescopeofeachofthesetestmethodsappearsinthesectioninwhichthetestmethodisdescribed.1.3Thetestmethodsappearinthefollowingsections:TestMethodSectionDimensionsandMass7-10BreakingStrength11ProcedureA—GrabTestMethod12-15ProcedureB—CutStripTestMethod16Elongation17BurstingStrength18-21PunctureResistance22-25TearingStrength26ProcedureA—PendulumMethod27ProcedureB—TongueTearMethod28-31TrapezoidalTear32-35HydrostaticResistance36ProcedureA—MullenTypeTester37-40ProcedureB—RisingWaterColumnTester41-44AdhesionCoating(toFabrics)45-48StrengthofCoating49-53Tack-TearResistance54-58LowTemperatureBendTest59LowTemperatureImpactTest60Low-TemperatureCrackResistance61-65SeamStrength66-71AcceleratedHeatAging(OvenMethod)72-79DeadLoadSeamStrength80-83BlockingResistanceatElevatedTemperatures84-88CrushResistance89-93WickingofCoatedCloth94-981.4ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D573TestMethodforRubber—DeteriorationinanAirOvenD1349PracticeforRubber—StandardTemperaturesforTestingD1424TestMethodforTearingStrengthofFabricsbyFalling-Pendulum(Elmendorf-Type)ApparatusD2136TestMethodforCoatedFab...