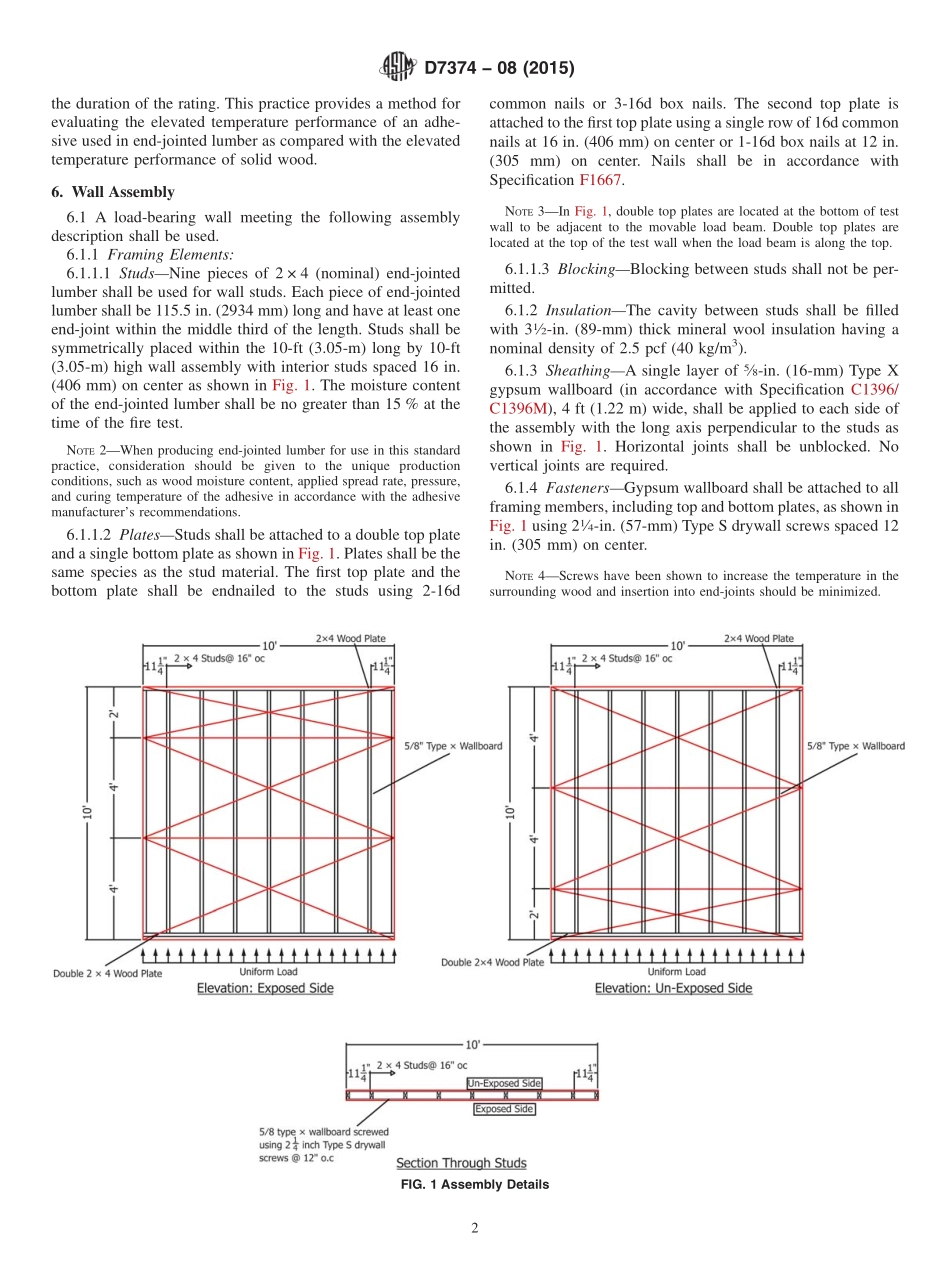

Designation:D7374−08(Reapproved2015)StandardPracticeforEvaluatingElevatedTemperaturePerformanceofAdhesivesUsedinEnd-JointedLumber1ThisstandardisissuedunderthefixeddesignationD7374;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisstandardpracticeistobeusedtoevaluatetheelevatedtemperatureperformanceofadhesivesusedinend-jointedlumber.1.2Asymmetricwallassemblycontainingend-jointedlum-berstudsisexposedtoastandardfireexposurespecifiedinTestMethodsE119.1.3ThewallassemblyshallsustaintheappliedloadduringastandardfireexposurespecifiedinTestMethodsE119foraperiodof60minormore.1.4Thispracticeisusedtoevaluatetheperformanceofadhesivesusedinend-jointedlumbertoheatandflameundercontrolledconditions,butitdoesnotbyitselfincorporateallfactorsrequiredforfirehazardorfireriskassessmentunderactualfireconditions.1.5Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.6Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C1396/C1396MSpecificationforGypsumBoardD4688TestMethodforEvaluatingStructuralAdhesivesforFingerJointingLumberD6513PracticeforCalculatingtheSuperimposedLoadonWood-frameWallsforStandardFire-ResistanceTestsE119TestMethodsforFireTestsofBuildingConstructionandMaterialsF1667SpecificationforDrivenFasteners:Nails,Spikes,andStaples2.2OtherStandards:ANSI/AF&PANDSNationalDesignSpecificationforWoodConstruction33.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1end-jointedlumber—lumbercontainingoneormoreend...