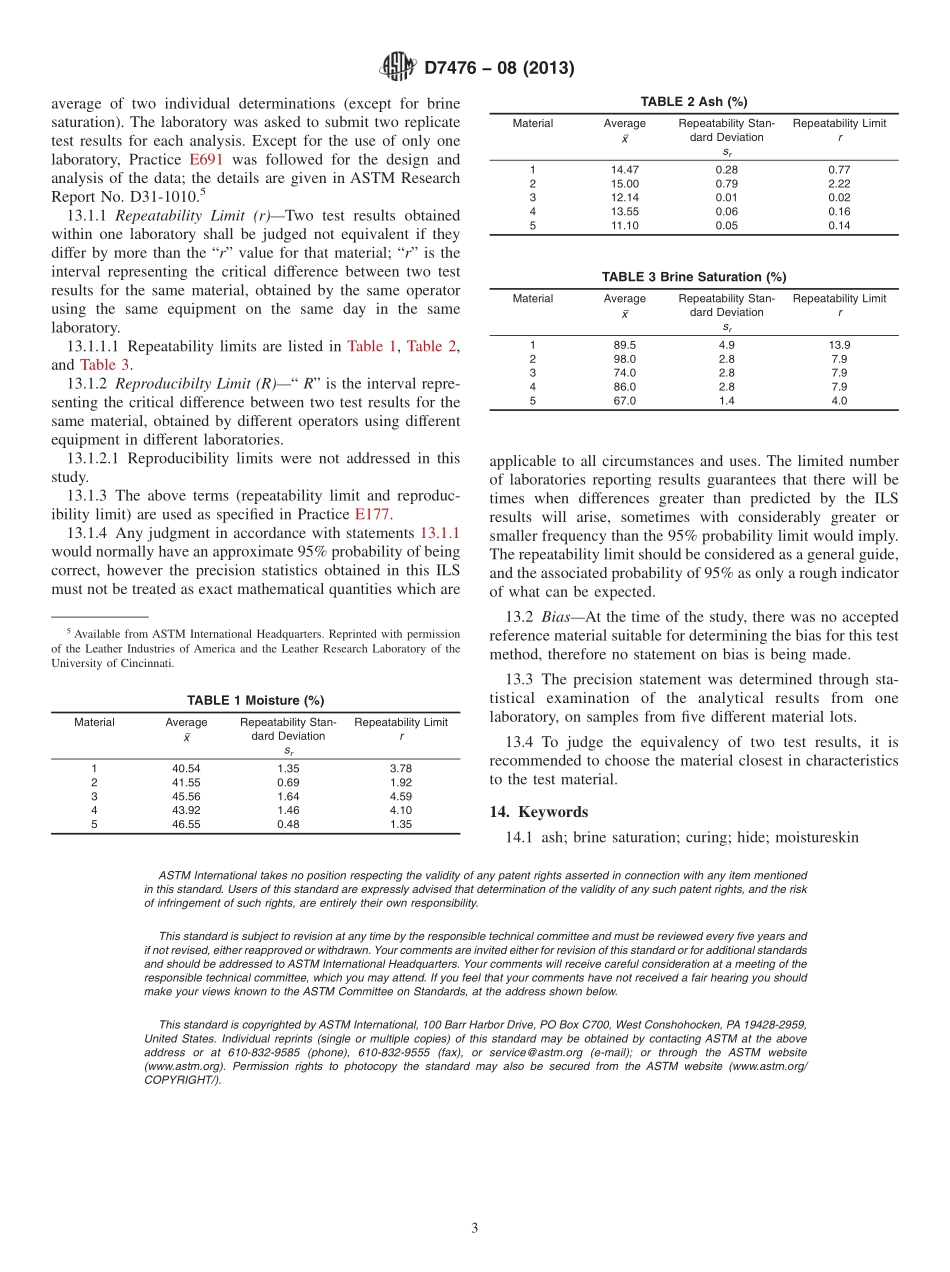

Designation:D7476−08(Reapproved2013)StandardTestMethodforBrineSaturationValueofCured(Salt-Preserved)HidesandSkins1ThisstandardisissuedunderthefixeddesignationD7476;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoverstheestimationofdegreeofsaturationofthebrinecontentofcured(salt-preserved)hidesandskinscontaining40%ormoremoisture.1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2,3D6715PracticeforSamplingandPreparationofFreshorSalt-Preserved(Cured)HidesandSkinsforChemicalandPhysicalTestsE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1Definitions:3.1.1Thetermsanddefinitionsemployedwithinthistestmethodarecommonlyusedinnormallaboratorypracticeandrequirenospecialcomment.4.SummaryofTestMethod4.1Themoisture(volatilematterbyovendrying)andashcontentofacompositehideorskinsamplearedetermined.Forpurposesofcalculationtheashisassumedtobeequivalenttosodiumchlorideandthemoistureisassumedtobeequivalenttowater.Thepercentratioofashtomoistureiscalculated.Thisratiotimes100isdividedby35.9(whichisthepercentsalttomoistureratioinasaturatedsodiumchloride(brine)solutionat20°C(68°F))toestimatethepercentofsaturationinthebrinesolutioninthehidesorskins.NOTE1—Asaturatedsolutionofsodiumchlorideat20°C(68°F)contains26.4%byweightofNaCl.Therefore,in100gofthatsaturatedsolutiononly73.6g(100−26.4g)iscontributedbywater....