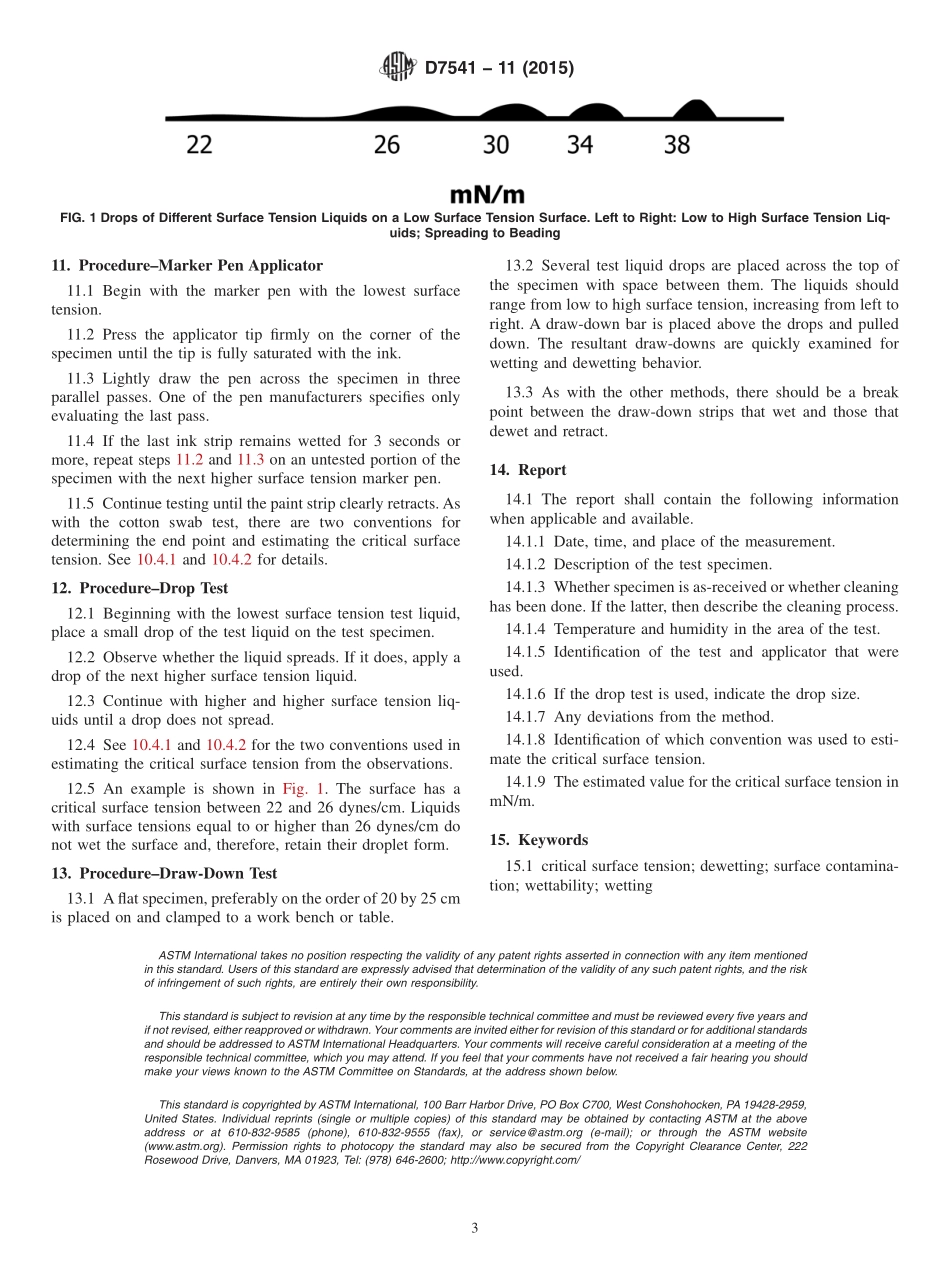

Designation:D7541−11(Reapproved2015)StandardPracticeforEstimatingCriticalSurfaceTensions1ThisstandardisissuedunderthefixeddesignationD7541;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoversproceduresforestimatingvaluesofthecriticalsurfacetensionofsurfacesbyobservingthewettinganddewettingofaseriesofliquids(usuallyorganicsolvents)appliedtothesurfaceinquestion.1.2Anothertechnique,measurementofthecontactangles,θ,ofaseriesoftestliquidsandplottingcosθversussurfacetension(Zismanplots),providesdatathatallowthedetermi-nationofmoreexactvaluesforcriticalsurfacetension.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D2578TestMethodforWettingTensionofPolyethyleneandPolypropyleneFilms2.2NordtestStandards:3NTpoly176SpreadingSurfaceTensionbytheAppliedDropletMethod.3.Terminology3.1Definitions:3.1.1criticalsurfacetension,n—thesurfacetensionofahypotheticalliquidthatwouldjustspontaneouslyspreadifappliedasadroptothesurfaceinquestion;anyliquidwithasurfacetensionlowerthanthecriticalsurfacetensionwillspreadspontaneously.4.SummaryofPractice4.1Inthispractice,aseriesofliquidsofgraduallyincreas-ingsurfacetensionareappliedtoasurfaceintheformofdrops,narrowstrips,orspots.Dropsmaybeappliedusingadropper,syringeorotherdevicecapableofproducingindi-vidualdrops.Liquidstripsorspotsareappliedtothesurfacebyswabbingwithsaturatedcottonswabsorbyanothertypeofapplicator,suchasonethatissimilartoamarkerpen.Inthecaseofthedrop,theobserverdetermin...