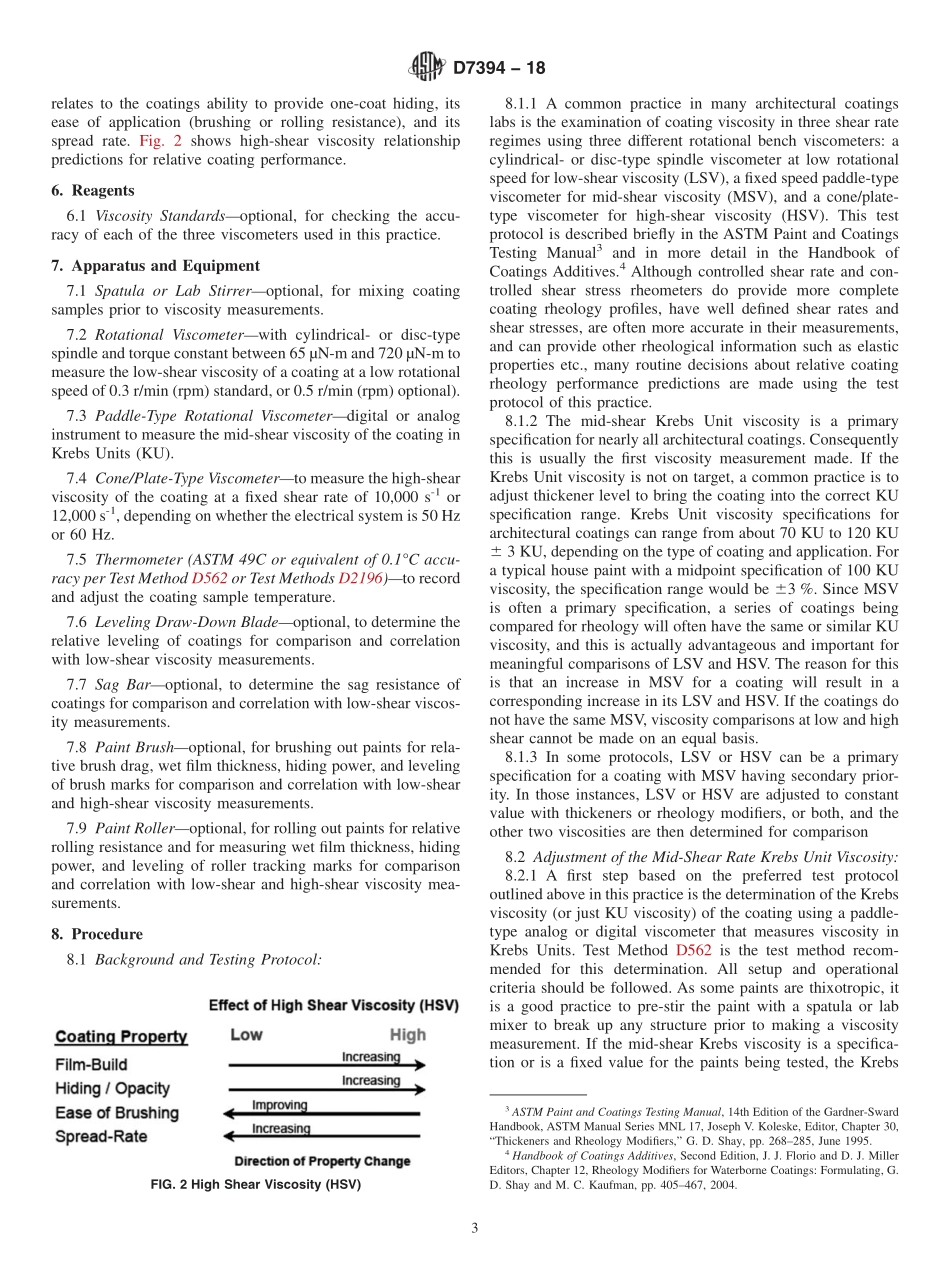

Designation:D7394−18StandardPracticeforRheologicalCharacterizationofArchitecturalCoatingsusingThreeRotationalBenchViscometers1ThisstandardisissuedunderthefixeddesignationD7394;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticedescribesapopularindustryprotocolfortherheologicalcharacterizationofwaterbornearchitecturalcoatingsusingthreecommonlyusedrotationalbenchviscom-eters.Eachviscometeroperatesinadifferentshearrateregimefordeterminationofcoatingviscosityatlowshearrate,midshearrate,andathighshearraterespectivelyasdefinedherein.Generalguidelinesareprovidedforpredictingsomecoatingperformancepropertiesfromtheviscositymeasurementsmade.Withappropriatecorrelationsandsubsequentmodifica-tionoftheperformanceguidelines,thispracticehaspotentialforcharacterizationofothertypesofaqueousandnon-aqueouscoatings.1.2Thevaluesincommonviscosityunits(KrebsUnits,KUandPoise,P)aretoberegardedasstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D562TestMethodforConsistencyofPaintsMeasuringKrebsUnit(KU)ViscosityUsingaStormer-TypeViscom-eterD869TestMethodforEvaluatingDegreeofSettlingofPaintD1005TestMethodforMeasurementofDry-FilmThick-nessofOrganicCoatingsUsingMicrometersD1200TestMethodforViscositybyFordViscosityCupD2196TestMethodsforRheo...