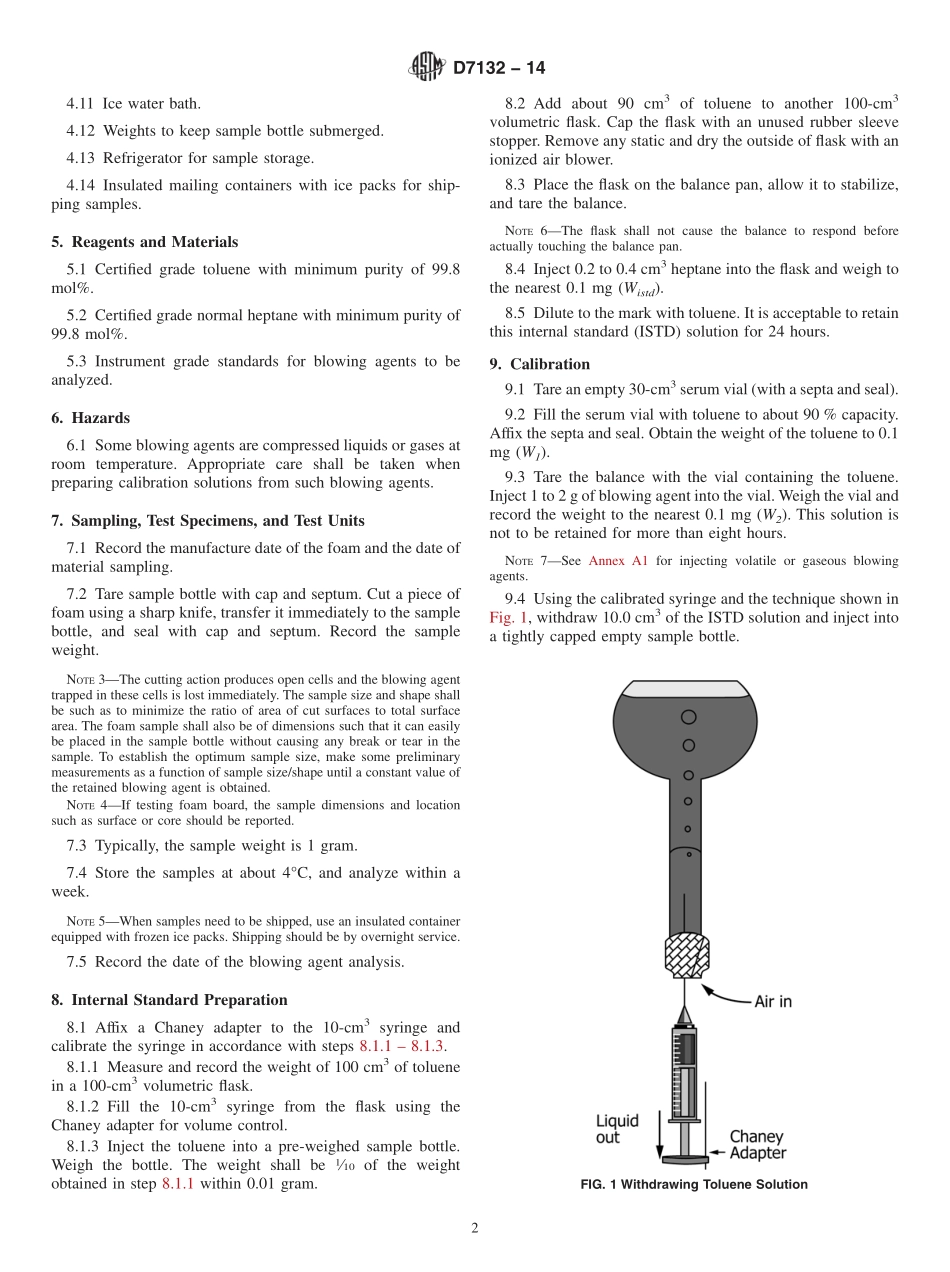

Designation:D7132−14StandardTestMethodforDeterminationofRetainedBlowingAgentinExtrudedPolystyreneFoam1ThisstandardisissuedunderthefixeddesignationD7132;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodcoversthedeterminationofretainedblowingagentinextrudedpolystyrenefoam.1.2Thistestmethodappliestoorganicblowingagentswhichlendthemselvestoaconvenientanalysisbygaschro-matography.Themethodisnotapplicabletoblowingagentssuchasnitrogen,carbondioxide,orwater.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesandtodeterminetheapplicabilityofregulatorylimitationspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.2.SummaryofTestMethod2.1Polystyrenefoamsaremadewithavarietyofblowingagentssuchashydrocarbons,hydrofluorocarbons,ethers,ketones,andothervolatileorganicchemicals.Afractionoftheblowingagentusedinthemanufactureoffoamisretainedintheproduct,someresidinginthecellwallsandsomeentrappedinsidethecells.Thistestmethodisbasedonreleasingtheretainedblowingagentbydissolvingthepolystyrenefoaminasolvent,suchastoluene,andthenanalyzingthesolutionforitscomponentsbygaschromatography.Aninternalstandardisusedasareferenceanalyteandcalibrationofthegaschro-matograph(GC)withstandardsolutionsallowsconversionoftheGCresponsetotheamountofblowingagentretainedinthefoammatrix.3.Interferences3.1Thegaschromatogramhasthepotentialtocontainasignal(s)fromthepolymermatrixthatinterfereswiththesignal(s)fromtheblowingagentcomponents.Testcalibrationsolutionswithandwithoutthepolymermatrixtoruleoutanyinterference.Thesecalibrationsolutionsshallconta...