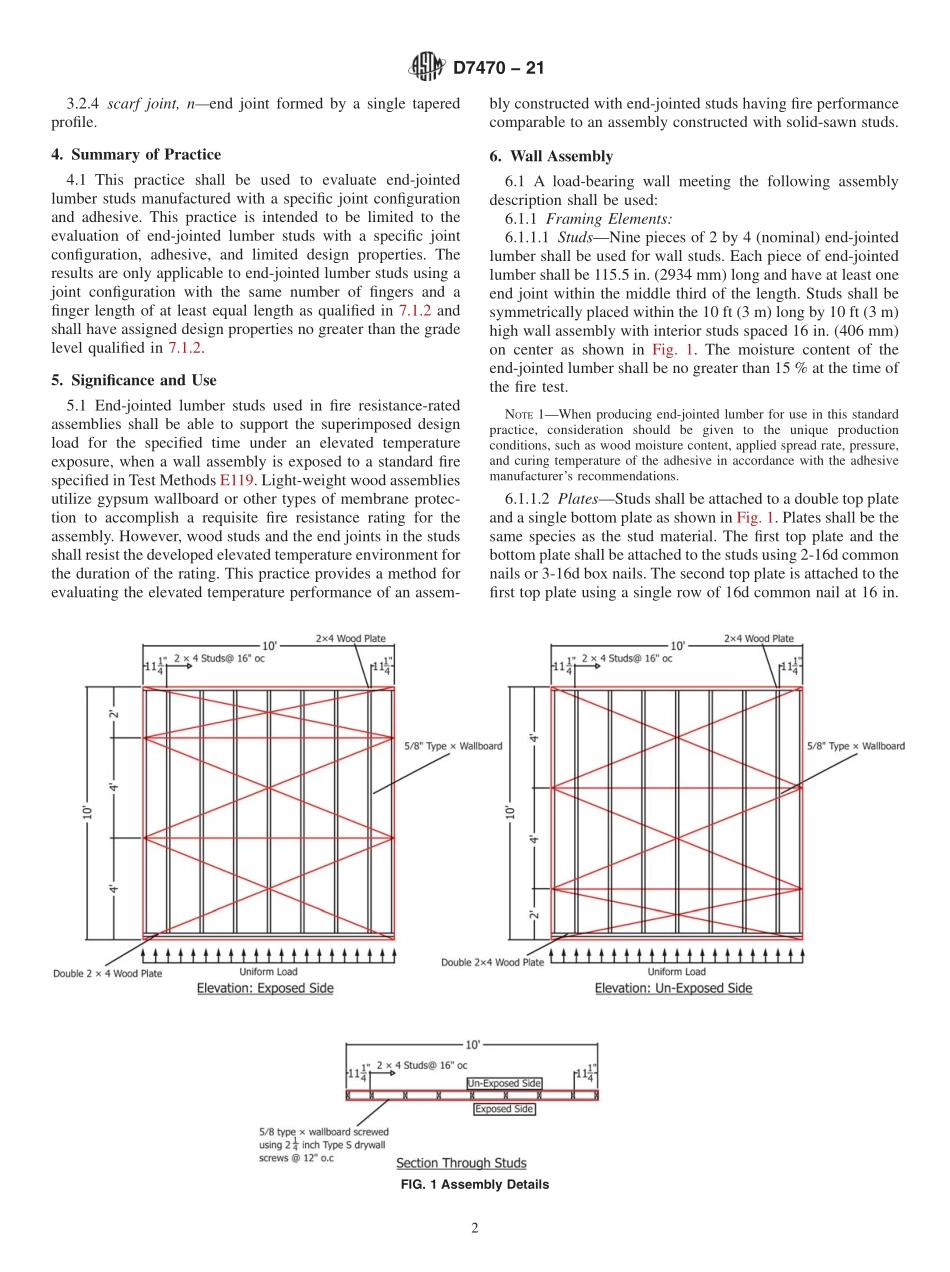

Designation:D7470−21StandardPracticeforEvaluatingElevatedTemperaturePerformanceofEnd-JointedLumberStuds1ThisstandardisissuedunderthefixeddesignationD7470;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticeistobeusedtoevaluatetheelevatedtemperatureperformanceofend-jointedlumberstuds.1.2Asymmetricwallassemblycontainingend-jointedlum-berstudsisexposedtoastandardfireexposurespecifiedinTestMethodsE119.1.3End-jointedlumberstudsaredeemedqualifiedifthewallassemblyresistsastandardfireexposurespecifiedinTestMethodsE119foraperiodof60minormore.Qualificationofend-jointedlumberstudsarerestrictedtothejointconfigura-tionandadhesivetested.1.4Thispracticeisusedtoevaluatetheperformanceofend-jointedlumberstudstoheatandflameundercontrolledconditions,butdoesnotbyitselfincorporateallfactorsrequiredforfirehazardorfireriskassessmentunderactualfireconditions.1.5Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.6Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.7Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2C1396/C1396MSpecificationforGypsumBoardD9TerminologyRelatingtoWoodandWood-BasedProd-uctsD4688TestMethodforEvaluatingStructuralAdhesivesforFingerJointingLumberD6513PracticeforCalculatingtheSuperimposedLoadonWood-frameWallsforStand...