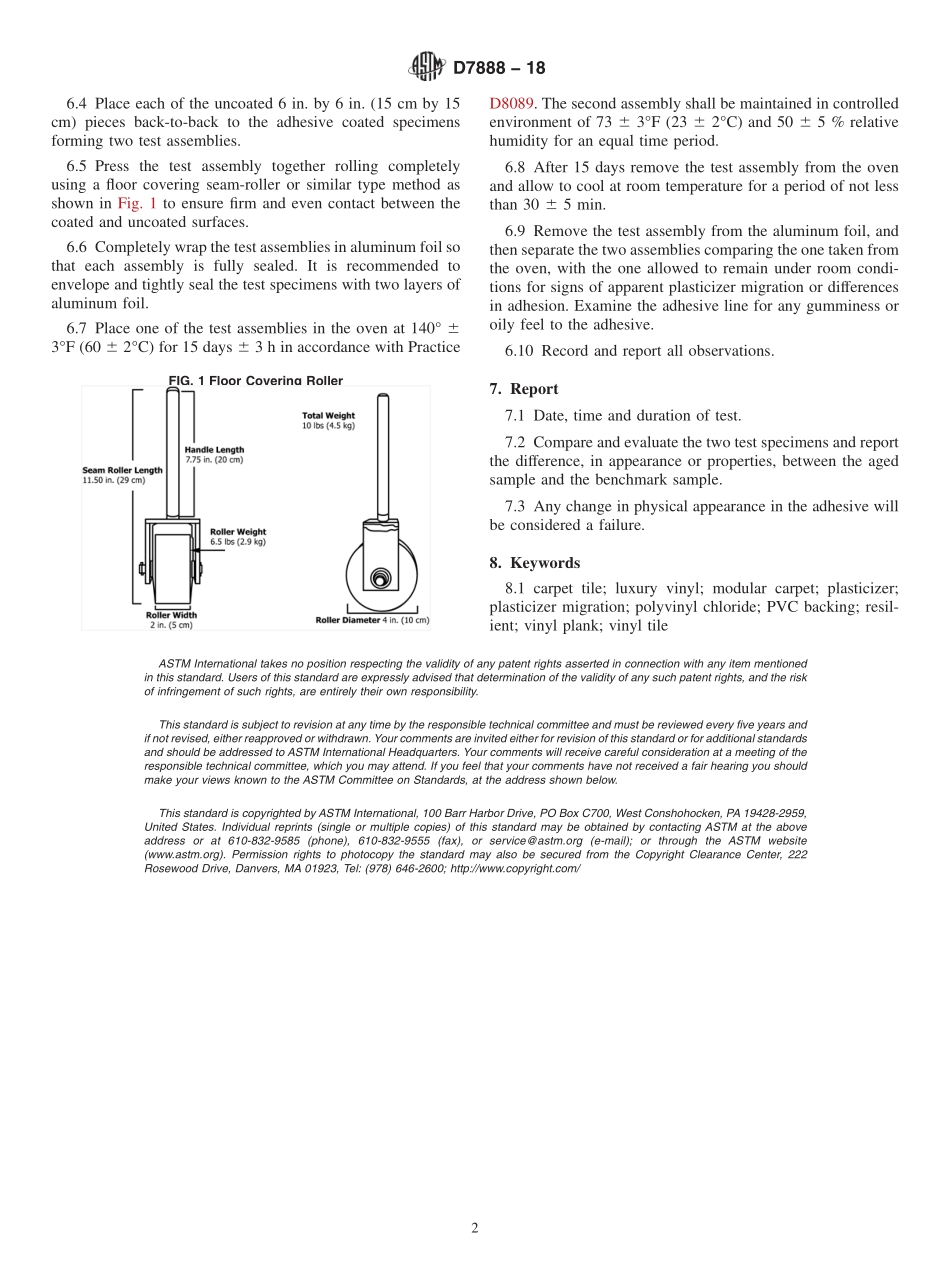

Designation:D7888−18StandardPracticeforEvaluatingAdhesiveandtheEffectsofPlasticizerFoundWithinPolyvinylChloride-BackedFloorCoverings1ThisstandardisissuedunderthefixeddesignationD7888;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisstandardwillprovideaqualitativemeanstodeter-minethepotentialeffectsofplasticizerscontainedwithinpolyvinylchloride(PVC)floorcoveringmaterialsonaspecificadhesive.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D123TerminologyRelatingtoTextilesD907TerminologyofAdhesivesD8089PracticeforAcceleratedHeatAgingforFloorCov-eringAdhesivesF141TerminologyRelatingtoResilientFloorCoverings3.Terminology3.1Definitions:3.1.1plasticizer,n—additivesthatincreasetheplasticityorfluidityofamaterial;achemicaladdedespeciallytorubbersandresinstoimpartflexibility,workability,orelasticity.3.1.2polyvinylchloride(PVC),n—athermoplasticpolymerusedinmanyfloorcoveringmaterials.4.SignificanceandUse4.1Plasticizermigrationisdetrimentaltomanyadhesives,includinghotmelts,whichcouldbepossiblyusedinconjunc-tionwithPVCbackedflooringmaterials,whetherresili...