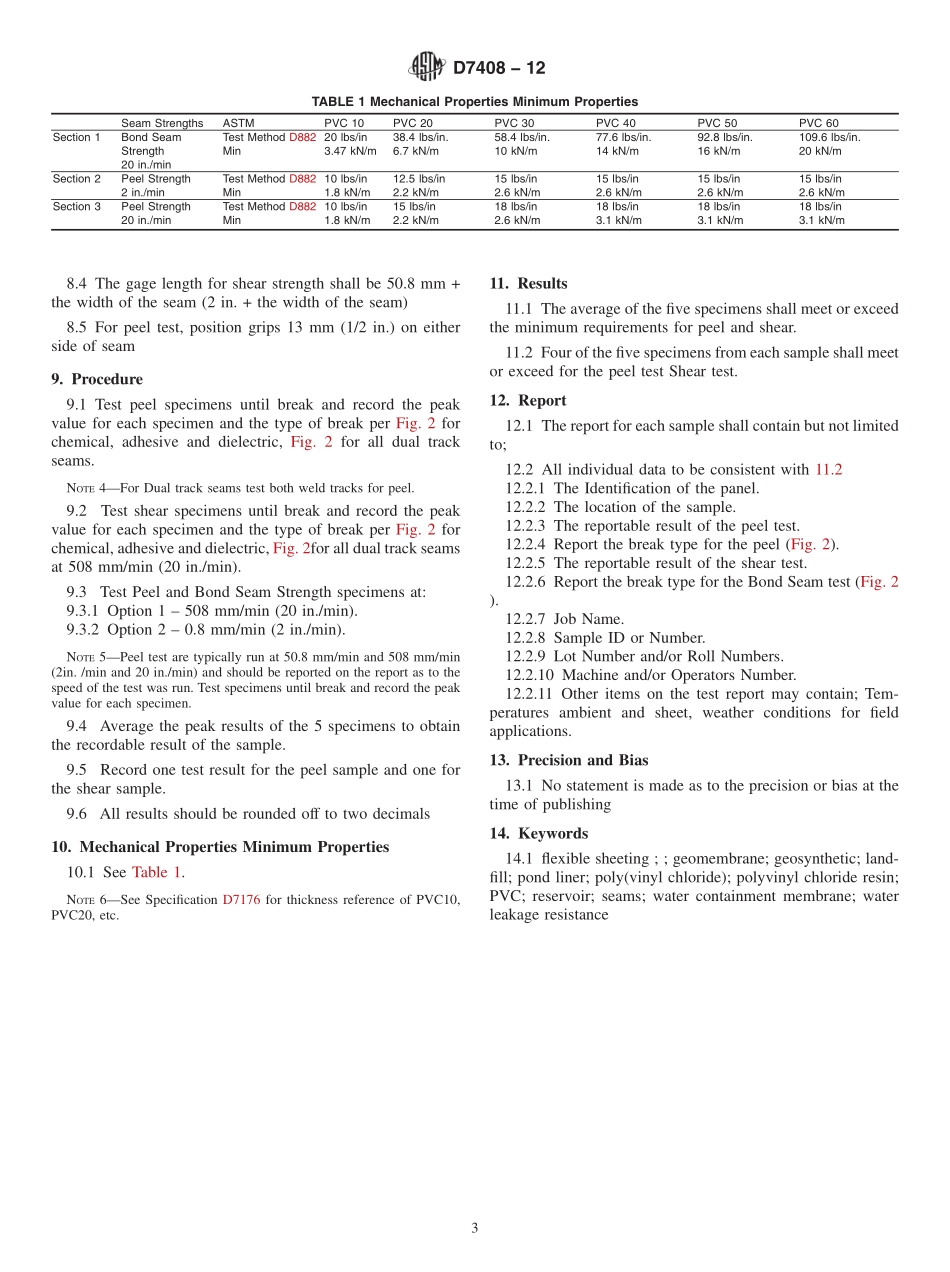

Designation:D7408−12StandardSpecificationforNonReinforcedPVC(PolyvinylChloride)GeomembraneSeams1ThisstandardisissuedunderthefixeddesignationD7408;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThisspecificationcoverstheminimumvaluesforseamsfabricatedintounreinforcedPVCgeomembranesinfactoryandfieldapplications.1.2ThisspecificationcoversPVCGeomembranesinthick-nessof.25through1.52mm(0.010through0.060in.)1.3Inadditiontostructuralcharacteristics,thespecifiershallevaluateothercharacteristicsbeyondthescopeofthisspecificationthataffectthefinalchoiceofconstruction.Theseinclude,butarenotlimitedto,functional,legal,insuranceandeconomicconsiderations.1.4Thisspecificationisnotintendedtoexcludeproductsorsystemsnotcoveredbythereferenceddocuments.1.5Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.6Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D638TestMethodforTensilePropertiesofPlasticsD882TestMethodforTensilePropertiesofThinPlasticSheetingD4439TerminologyforGeosyntheticsD7176SpecificationforNon-ReinforcedPolyvinylChloride(PVC)GeomembranesUsedinBuriedApplications3.Terminology3.1Definitions:3.1.1chemicalfusionseams,n—useofachemicalagenttodissolvethesurfaceofthegeomembraneforbonding.3.1.2adhesiveorbodiedsolvent,n—theseseamsaretypi-callyproducedbyapplyinganadhesivetobothsidesofthesheettobebondedandthenpressureisappliedtothetopsheetwiththebottomsheetsupportedbyflatafirmsurface3.1.3thermalfusion,n—alsokno...