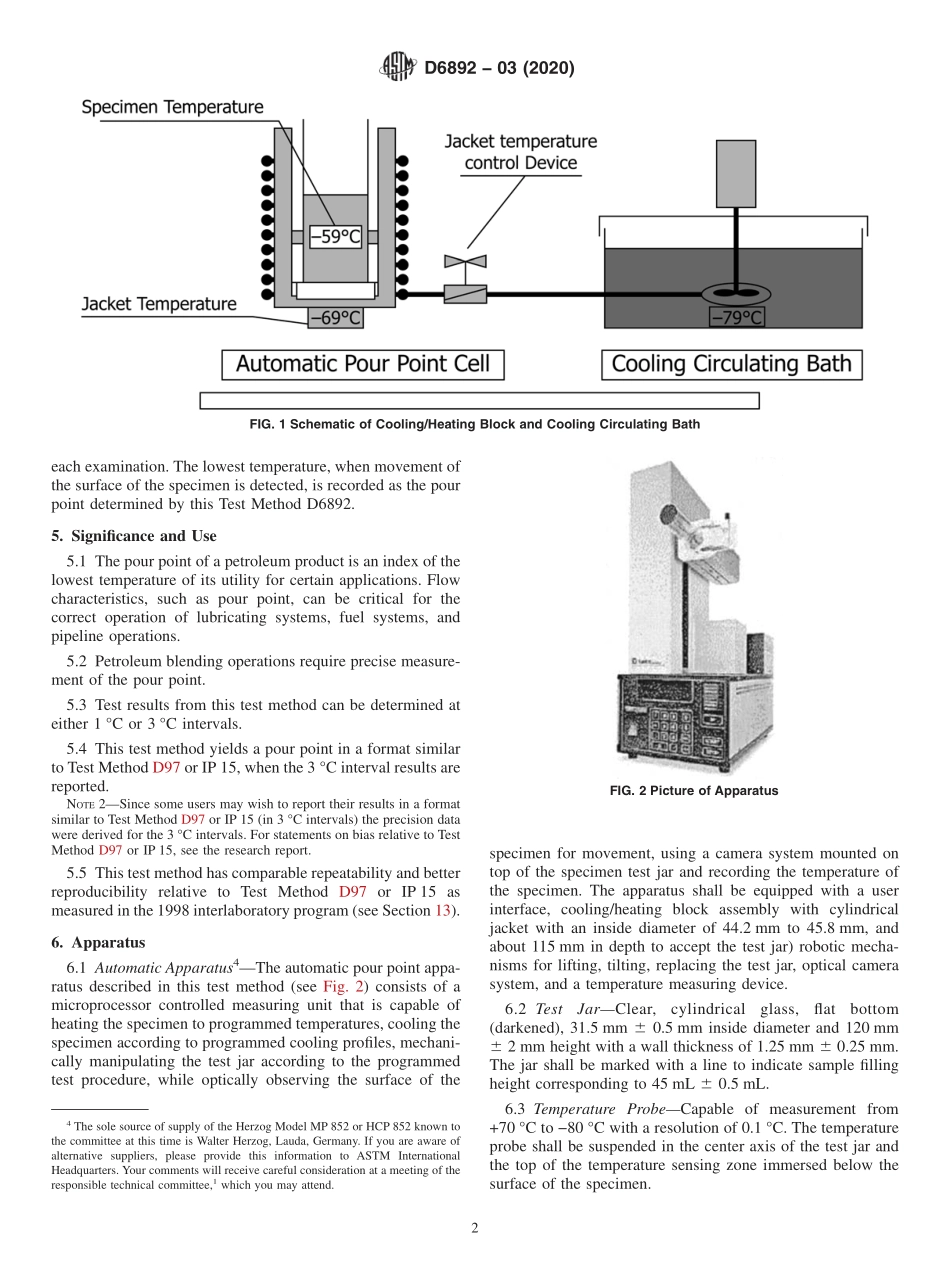

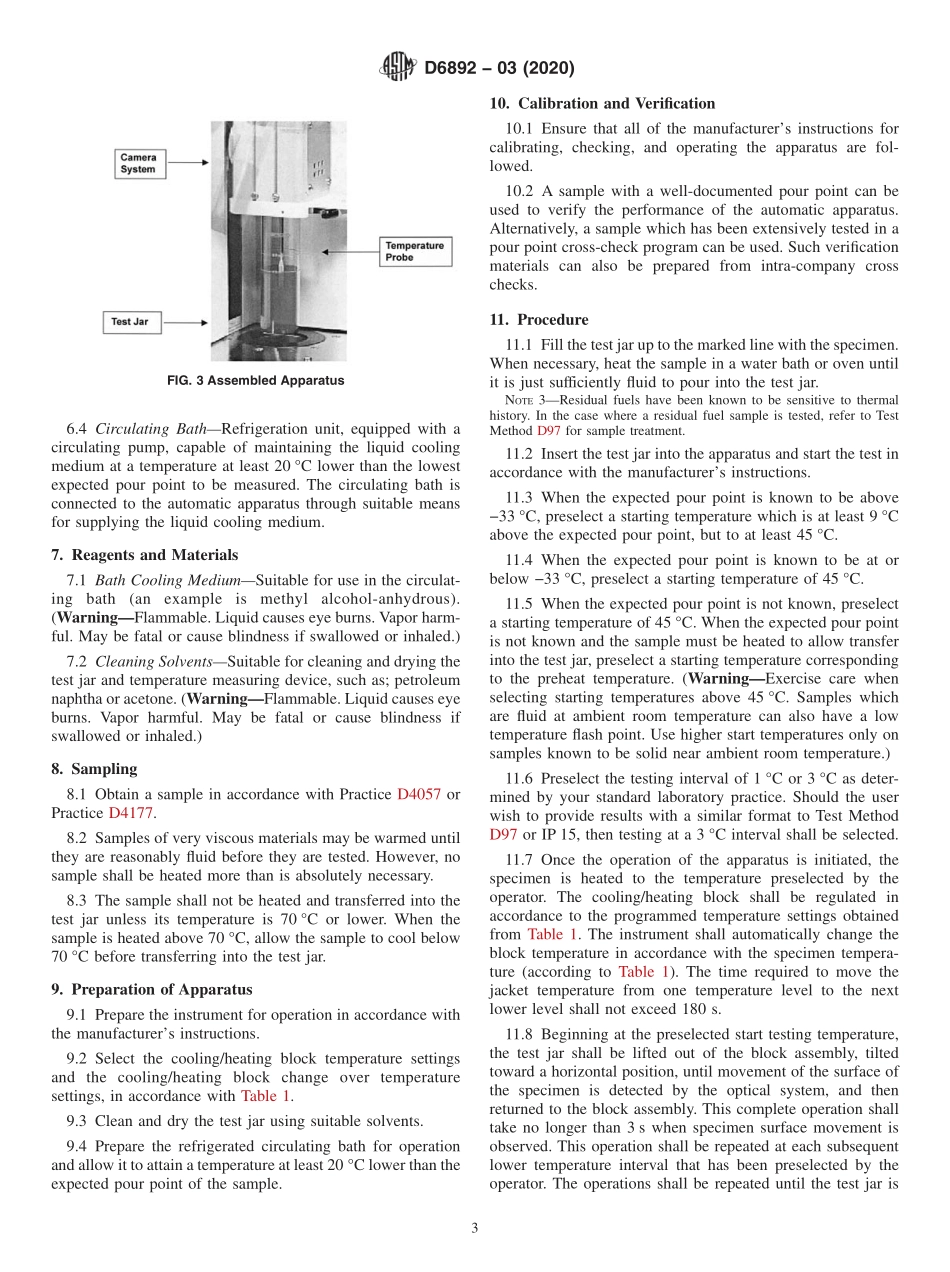

Designation:D6892−03(Reapproved2020)StandardTestMethodforPourPointofPetroleumProducts(RoboticTiltMethod)1ThisstandardisissuedunderthefixeddesignationD6892;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthepourpointofpetroleumproductsbyanautomaticinstrumentthattiltsthetestjartodetectmovementofthesurfaceofthetestspecimenwithanopticaldevice,afterbeingremovedfromaregulated,stepped-bathcoolingjacket.1.2Thistestmethodisdesignedtocovertherangeoftemperaturesfrom−57°Cto+51°C;however,therangeoftemperaturesincludedinthe1998interlaboratorytestprogramonlycoveredthetemperaturerangefrom−51°Cto−11°C.1.3Testresultsfromthistestmethodcanbedeterminedateither1°Cor3°Ctestingintervals.1.4Thistestmethodisnotintendedforusewithcrudeoils.NOTE1—Theapplicabilityofthistestmethodonresidualfuelsampleshasnotbeenverified.Forfurtherinformationontheapplicability,referto13.4.1.5ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.6Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.7Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D97TestMethodforPourPointofPetroleumProductsD4057PracticeforManualSamplingofPetroleumandPetroleumProductsD4177PracticeforAutomaticSamplingofPetroleumandPetroleumProducts2.2EnergyInstituteStand...