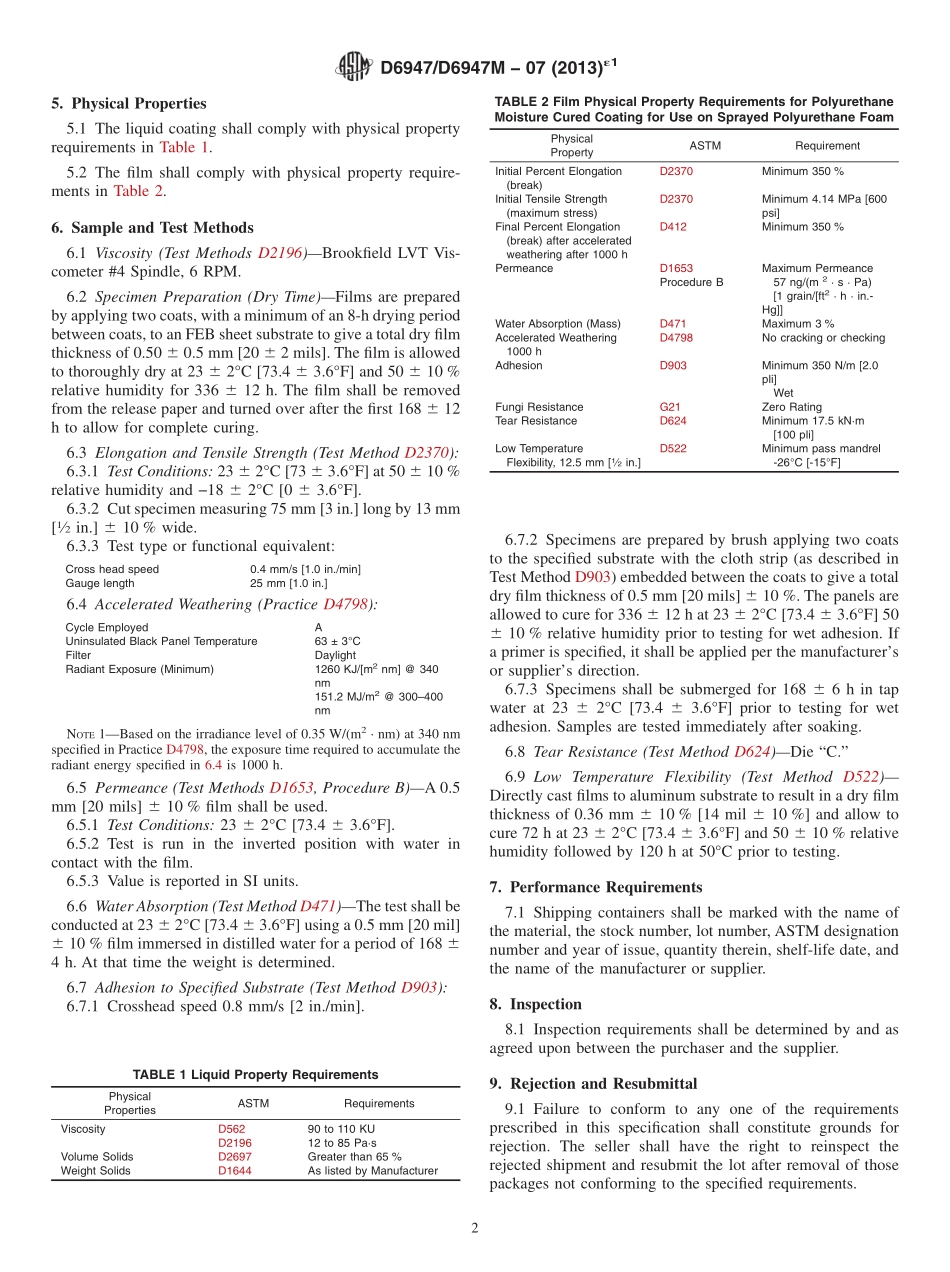

Designation:D6947/D6947M−07(Reapproved2013)´1StandardSpecificationforLiquidAppliedMoistureCuredPolyurethaneCoatingUsedinSprayPolyurethaneFoamRoofingSystem1ThisstandardisissuedunderthefixeddesignationD6947/D6947M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ε1NOTE—UnitsinformationwaseditoriallycorrectedinJuly2013.1.Scope1.1Thisspecificationcoversasinglecomponent,moisturecured,elastomericurethanepolymercoatingusedasaprotec-tivecoatingforspraypolyurethanefoamroofingsystems.1.2Thisspecificationdoesnotprovideguidanceforappli-cation.1.3ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.4Thefollowingprecautionarycaveatpertainsonlytothetestmethodportions,Sections5and6.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatoryrequirementspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D16TerminologyforPaint,RelatedCoatings,Materials,andApplicationsD412TestMethodsforVulcanizedRubberandThermoplas-ticElastomers—TensionD471TestMethodforRubberProperty—EffectofLiquidsD522TestMethodsforMandrelBendTestofAttachedOrganicCoatingsD562TestMethodforConsistencyofPaintsMeasuringKrebsUnit(KU)ViscosityUsingaStormer-TypeViscom-eterD624TestMethodforTearStrengthofConventionalVul-canizedRubberandThermoplasticElastomersD903TestMethodforPeelorStrippingStrengthofAdhe-siveBondsD1079TerminologyRelatingtoRoofingandWaterproofingD1644TestMethodsforNonvolatileContentofVarnishesD1653TestMethodsforWaterVaporTransmissio...