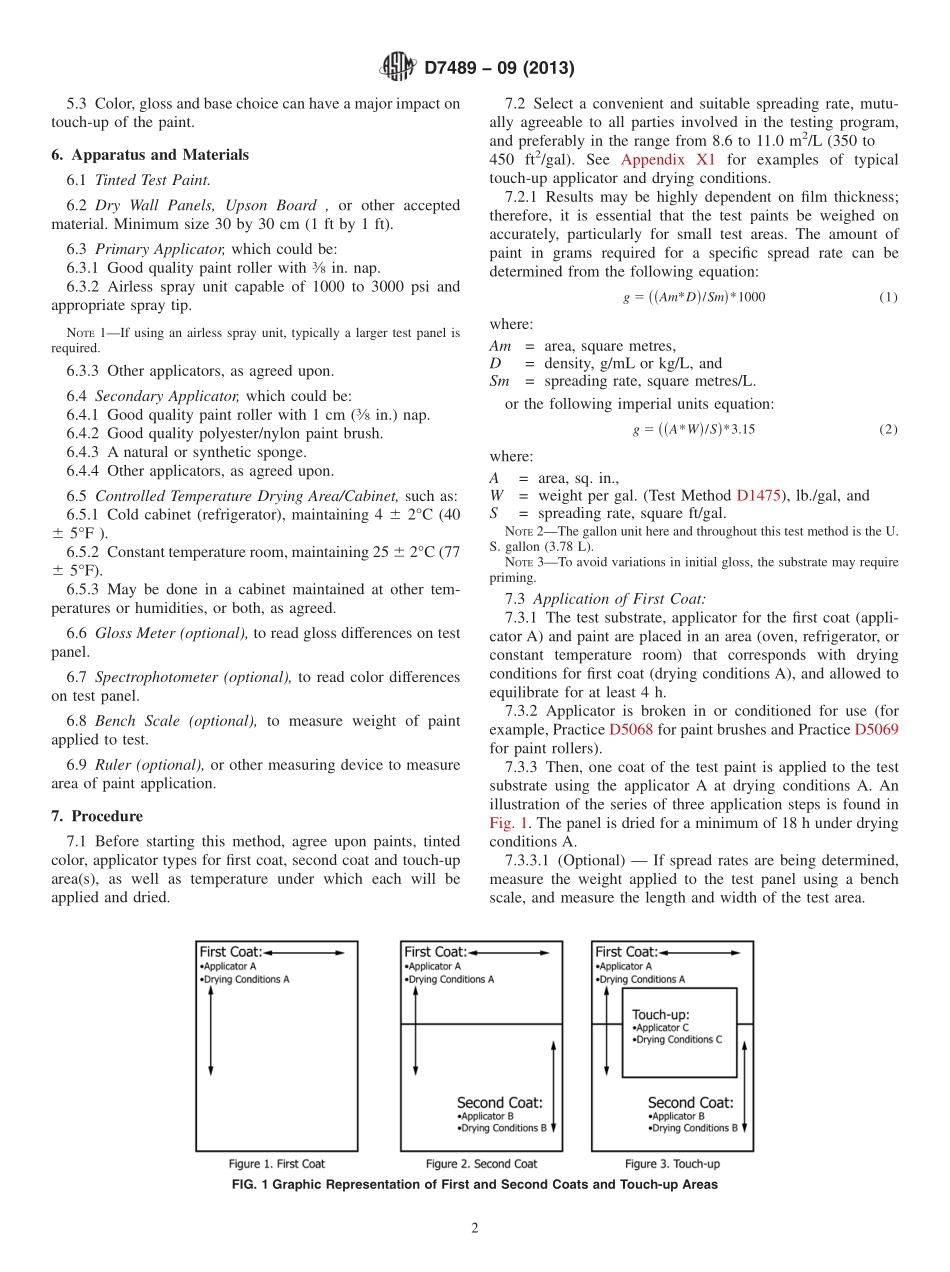

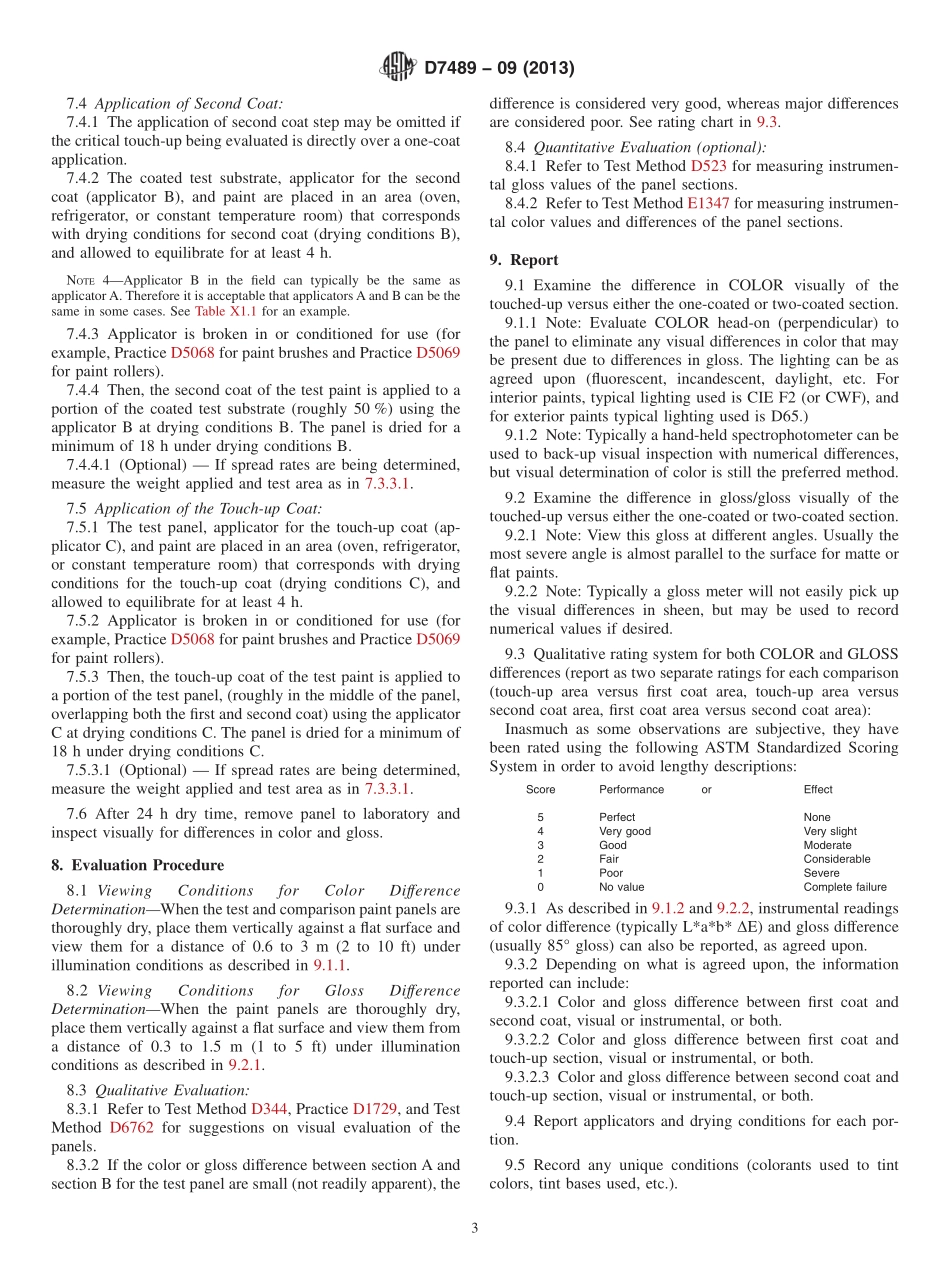

Designation:D7489−09(Reapproved2013)StandardPracticeforEvaluatingTouch-UpPropertiesofArchitecturalCoatingsunderVariousEnvironmentalConditions1ThisstandardisissuedunderthefixeddesignationD7489;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticedeterminestheabilityofapainttoberecoatedor“touchedup”insmallareas.Variationsincolor,gloss,andsheenthatresultinadifferentappearancefromtheoriginalpaintcanbeevaluatedvisually.1.2Thispracticedescribesevaluationoftouch-upcharac-teristicsinalaboratory-scalecontrolledenvironmentasop-posedtoafull-scalefieldenvironment.1.3Evaluationoftouch-uppropertiesunderconstantdryingconditionsisdescribed.Environmentalconditionscanbeadjustedtoincorporatehighorlowtemperaturedrying,orboth.Thechangesinapplicationtemperaturecanleadtolargerdifferencesintouch-upthanapplyingbothcoatsunderthesameenvironmentalconditions.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D344TestMethodforRelativeHidingPowerofPaintsbytheVisualEvaluationofBrushoutsD523TestMethodforSpecularGlossD1475TestMethodForDensityofLiquidCoatings,Inks,andRelatedProductsD1729PracticeforVisualAppraisalofColorsandColorDifferencesofDiffusely-IlluminatedOpaqueMaterialsD5068PracticeforPreparationofPaintBrushesforEvalu-ationD5069PracticeforPreparationofPaint-RollerCoversforEvaluationofArchitecturalCoatingsD6762TestMethodforDeterminingtheHidingPowerofPaintbyVisualEvaluationofSprayAppliedCoatingsE1347TestMethodforColorandColor-DifferenceMea-surementbyTristimulusColorimetry3.Terminology3.1Definitions:3.1.1touch-up,n—torepairvisualdifferencesin...