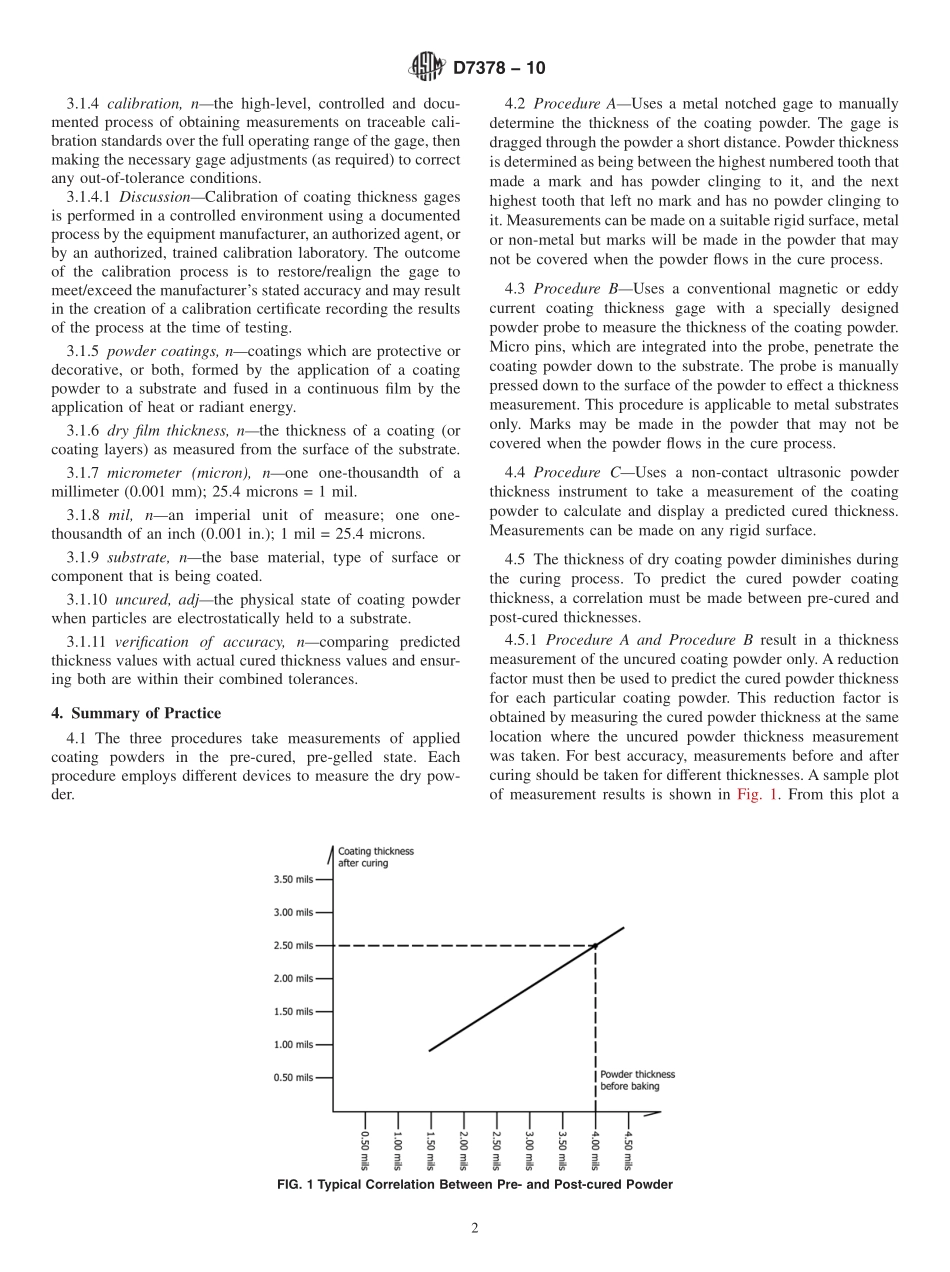

Designation:D7378−10StandardPracticeforMeasurementofThicknessofAppliedCoatingPowderstoPredictCuredThickness1ThisstandardisissuedunderthefixeddesignationD7378;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticedescribesthethicknessmeasurementofdrycoatingpowdersappliedtoavarietyofrigidsubstrates.Useofsomeoftheseproceduresmayrequirerepairofthecoatingpowder.Thispracticeisintendedtosupplementthemanufacturers’instructionsfortheoperationofthegagesandisnotintendedtoreplacethem.Itincludesdefinitionsofkeyterms,referencedocuments,thesignificanceanduseofthepractice,andtheadvantagesandlimitationsoftheinstruments.1.2Threeproceduresareprovidedformeasuringdrycoat-ingpowderthickness:1.2.1ProcedureA—Usingrigidmetalnotched(comb)gages.1.2.2ProcedureB—Usingmagneticoreddycurrentdryfilmthicknessgages.1.2.3ProcedureC—Usingnon-contactultrasonicpowderthicknessinstruments.1.3Coatingpowdersgenerallydiminishinthicknessduringthecuringprocess.Someoftheseproceduresthereforerequireareductionfactorbeestablishedtopredictcuredfilmthicknessofpowdercoatings.1.4ProcedureAandProcedureBmeasurethethickness(heightordepth)oftheappliedcoatingpowdersinthepre-cured,pre-gelledstate.Bycomparingresultstothemea-suredcuredpowderthicknessinthesamelocation,areductionfactorcanbedeterminedandappliedtofuturethicknessmeasurementsofthesamecoatingpowder.1.5ProcedureCresultsinapredictedthicknessvalueofthecuredstatebasedonacalibrationfortypicalcoatingpowders.Ifthepowderinquestionisnottypicalthenanadjustmentcanbemadetoaligngagereadingswiththeactualcuredvaluesasdeterminedbyothermeasurementmethods.1.6ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.7Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresp...