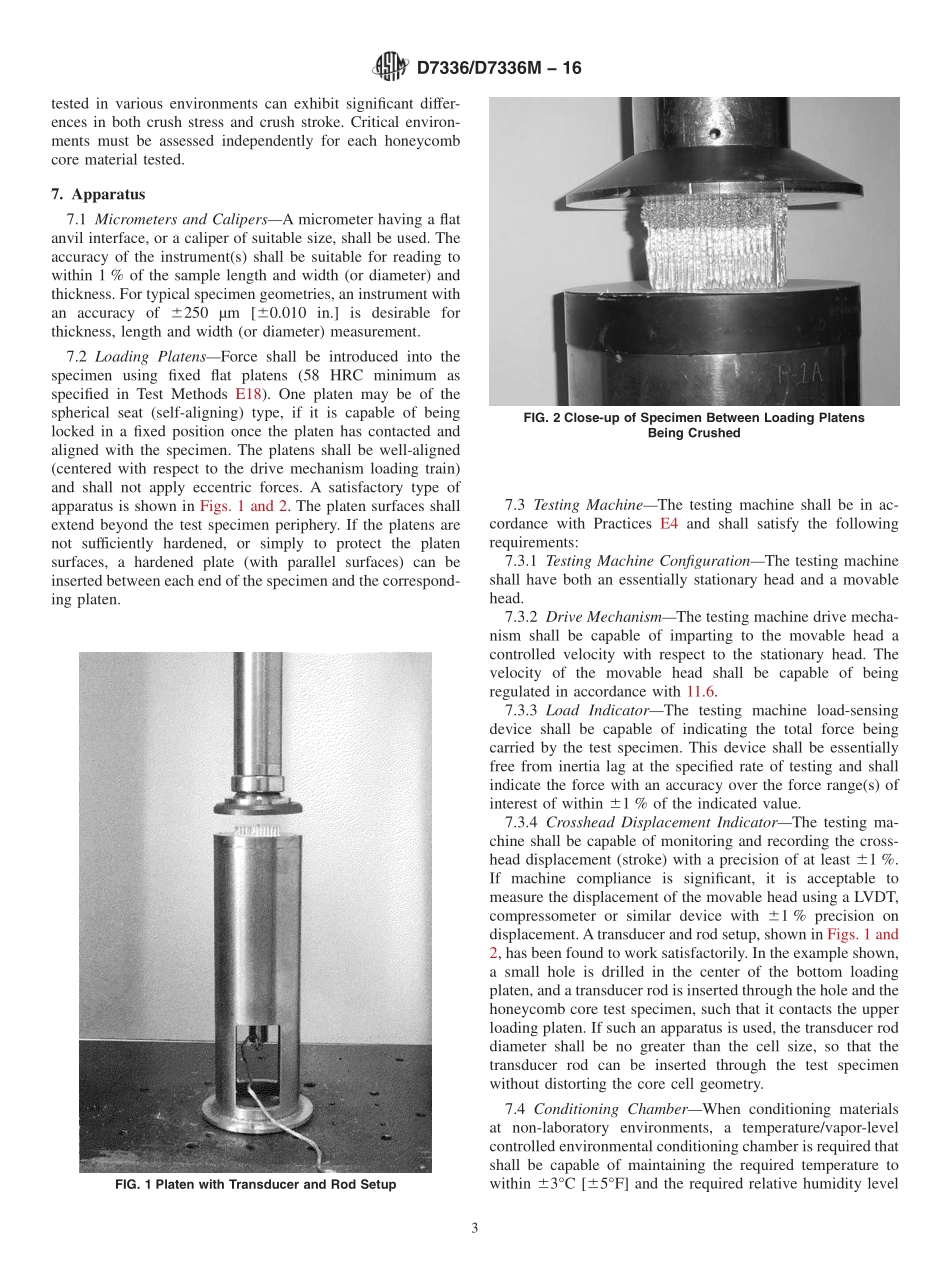

Designation:D7336/D7336M−16StandardTestMethodforStaticEnergyAbsorptionPropertiesofHoneycombSandwichCoreMaterials1ThisstandardisissuedunderthefixeddesignationD7336/D7336M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethoddeterminesthestaticenergyabsorptionproperties(compressivecrushstressandcrushstroke)ofhoneycombsandwichcorematerials.Thesepropertiesareusuallydeterminedfordesignpurposesinadirectionnormaltotheplaneoffacingsasthehoneycombcorematerialwouldbeplacedinastructuralsandwichconstruction.1.2Permissiblecorematerialsarelimitedtothoseinhon-eycombform.1.3Thistestmethodisnotintendedforuseincrushtestingofstabilizedhoneycombcorematerials(forwhichthefacingplanesurfacesofthehoneycombcorematerialaredippedinresintoresistlocalcrushing)orsandwichspecimens(forwhichfacingsarebondedtothehoneycombcorematerial).1.4ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.4.1Withinthetexttheinch-poundunitsareshowninbrackets.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C271/C271MTestMethodforDensityofSandwichCoreMaterialsD883TerminologyRelatingtoPlasticsD3878TerminologyforCompositeMaterialsD5229/D5229MTestMethodforMoistureAbsorptionProp-ertiesandEquilibriumConditioningofPolymerMatrixCompositeMaterialsE4PracticesforForceVerificationofTestingMachinesE6TerminologyRelatingtoMethodsofMechanicalTestingE18TestMethodsforRo...