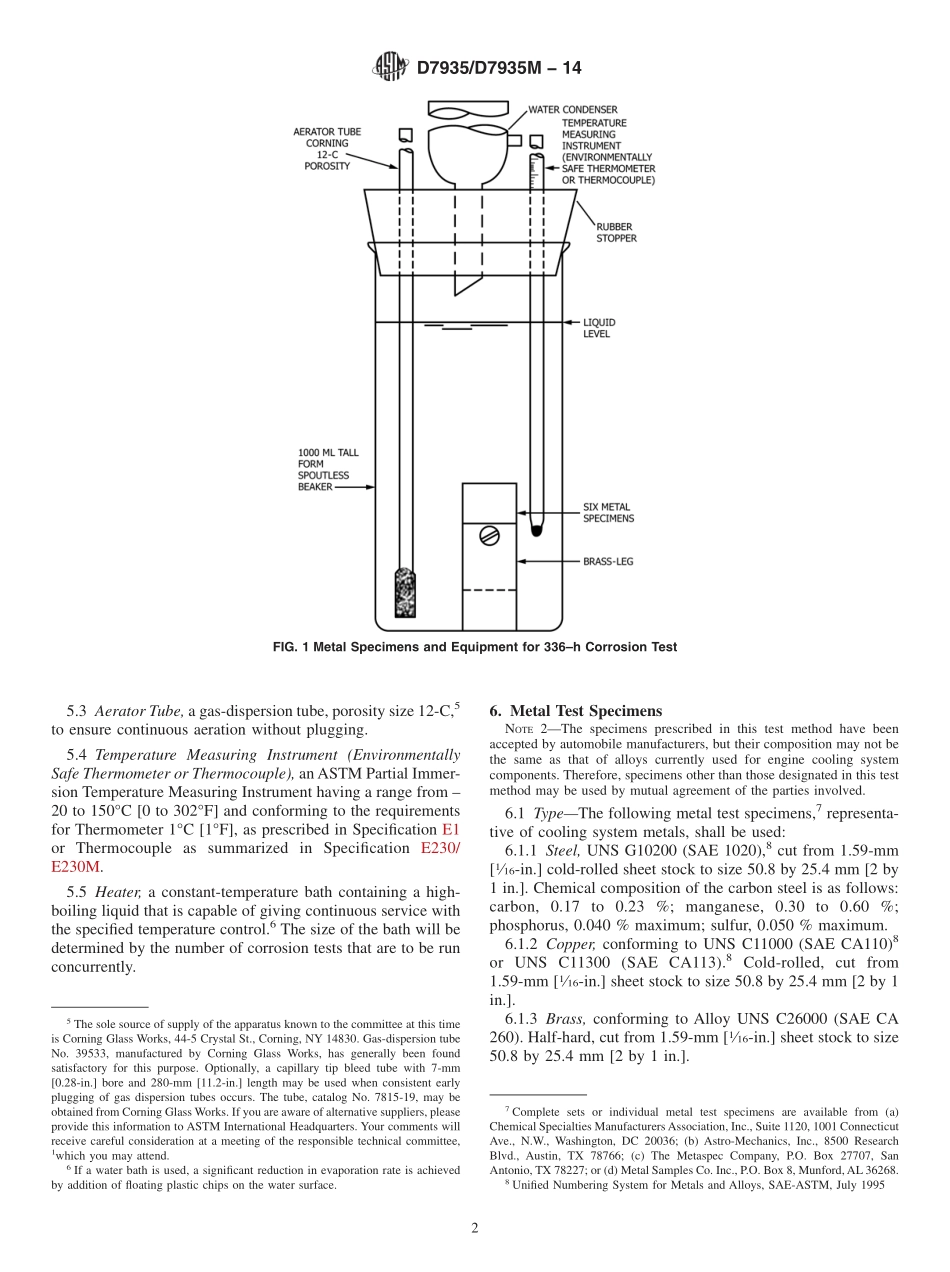

Designation:D7935/D7935M−14StandardTestMethodforCorrosionTestforNon-AqueousEngineCoolantsinGlassware1ThisstandardisissuedunderthefixeddesignationD7935/D7935M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversasimplebeaker-typeprocedureforevaluatingtheeffectsofnon-aqueousenginecoolantsonmetalspecimensundercontrolledlaboratoryconditions(seeAppendixX1).NOTE1—Formoreinformationonaqueousandnon-aqueousenginecoolants,see(Refs1-9).21.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.SomevalueshaveonlySIunitsbecausetheinch-poundequivalentsarenotusedinpractice.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Somespecifichazardsstatementsaregivenin10.1.7.2,10.1.7.3,and10.1.7.4.2.ReferencedDocuments2.1ASTMStandards:3B32SpecificationforSolderMetalB36/B36MSpecificationforBrassPlate,Sheet,Strip,AndRolledBarD1176PracticeforSamplingandPreparingAqueousSolu-tionsofEngineCoolantsorAntirustsforTestingPurposesD1384TestMethodforCorrosionTestforEngineCoolantsinGlasswareE1SpecificationforASTMLiquid-in-GlassThermometersE178PracticeforDealingWithOutlyingObservationsE230/E230MSpecificationandTemperature-ElectromotiveForce(emf)TablesforStandardizedThermocouples2.2ASTMAdjunct:4All-glassapparatusforcorrosiontest(2drawings)3.SummaryofTestMethod3.1Inthistestmethod,specimensofmetalstypicalofthosepresentinenginecoolingsystemsaretotallyimmersedinaeratedenginecoola...