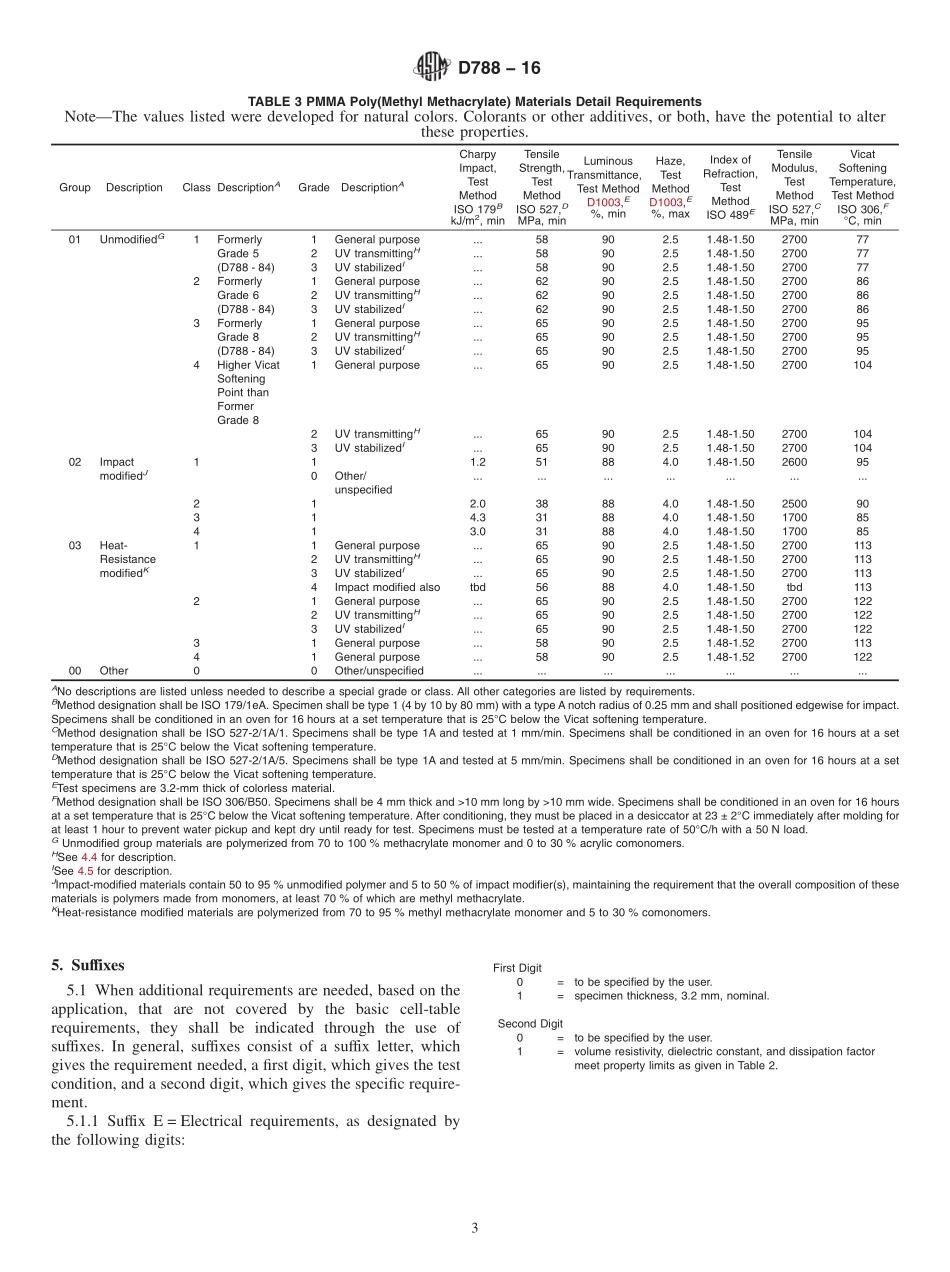

Designation:D788−16StandardClassificationSystemforPoly(MethylMethacrylate)(PMMA)MoldingandExtrusionCompounds1ThisstandardisissuedunderthefixeddesignationD788;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1ThepurposeofthisclassificationsystemistoprovideamethodofadequatelyidentifyingPMMAmaterialsusingasystemconsistentwiththatofClassificationSystemD4000.Itfurtherprovidesameansforspecifyingthesematerialsbytheuseofasimplelinecalloutdesignation.1.2Thisclassificationsystemcoverspoly(methylmethacry-late)moldingandextrusioncompounds.Thesecompoundsarepolymersbasedonmethylmethacrylate,andatleast70%ofthepolymershallbepolymerizedfrommethylmethacrylate.1.3Thepropertiesinthisclassificationsystemarethoserequiredtoidentifythecompositionscovered.Otherrequire-mentsnecessarytoidentifyparticularcharacteristicsimportanttospecificapplicationsshallbedescribedbyusingthesuffixesasgiveninSection5.1.4Acrylicmoldingandextrusioncompoundsareusedfrequentlyinapplicationswhereextremeclarityandtheabilitytoretainthatclarityandcolorundersevereweatheringandotherenvironmentalexposuresareofprimarysignificance.Whilethetestspecimenpropertiesofthisdocumentextendtotheevaluationofnonvirginmaterials,theusermusttakeprecautionstoensurethatpartsmadefromthesematerialsmeetthedesiredend-userequirements.Accordingly,thisspecifica-tionallowsfortheuseofthoseacrylicplasticmaterialsthatcanberecycled,reconstituted,andregroundprovidedthefollow-ing:1.4.1Therequirementsasstatedinthisspecificationaremet,and1.4.2Therequirementsoftheparticularend-useapplicationaremet.1.5Thisclassificationsystemandsubsequentlinecallout(specification)arenotintendedfortheselectionofmaterials,butonlyasameanstocalloutplasticmaterialstobeusedforthemanufactureof...