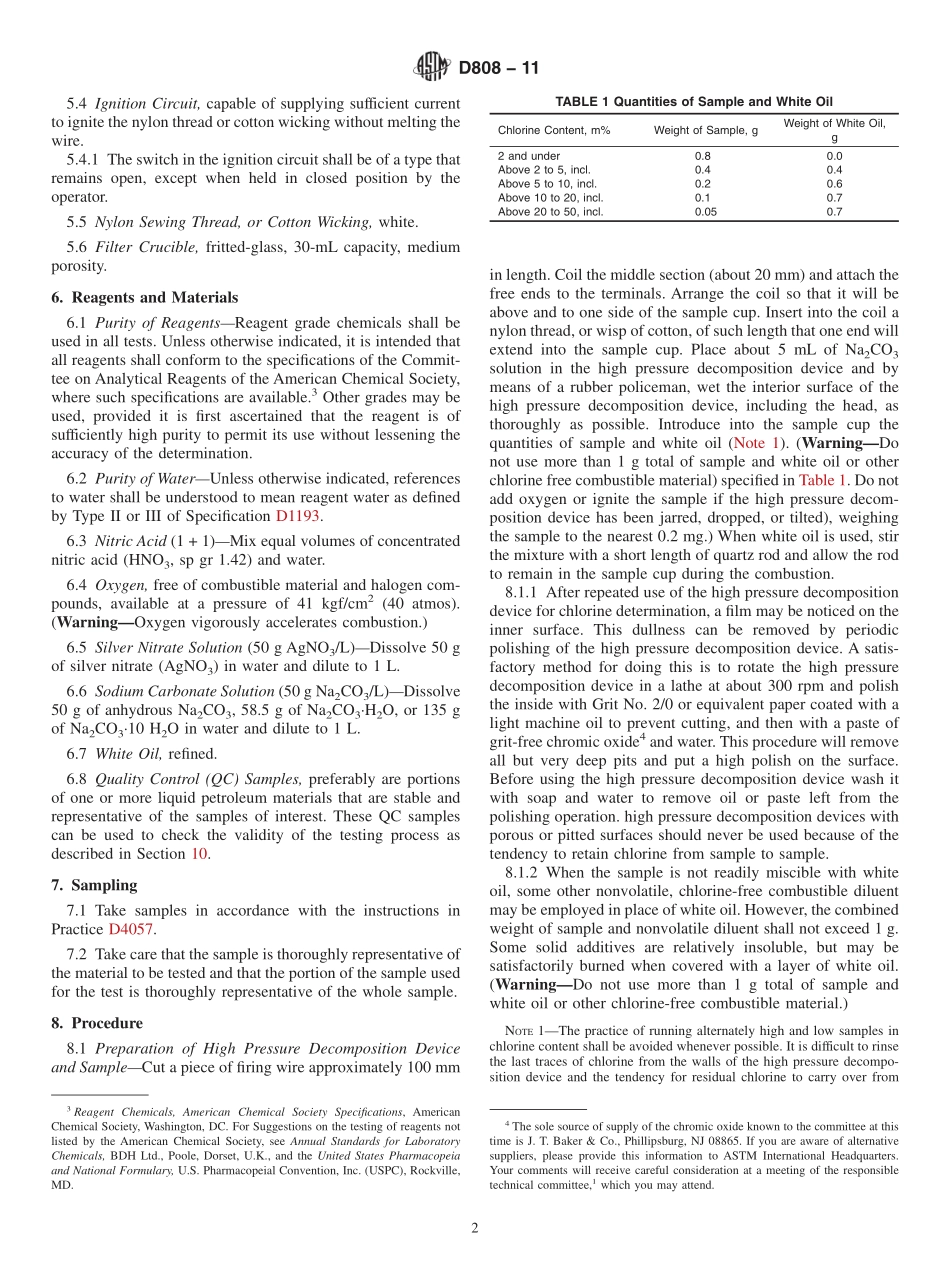

Designation:D808−11StandardTestMethodforChlorineinNewandUsedPetroleumProducts(HighPressureDecompositionDeviceMethod)1ThisstandardisissuedunderthefixeddesignationD808;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope*1.1Thistestmethodcoversthedeterminationofchlorineinlubricatingoilsandgreases,includingnewandusedlubricat-ingoilsandgreasescontainingadditives,andinadditiveconcentrates.Itsrangeofapplicabilityis0.1to50m%chlo-rine.Theprocedureassumesthatcompoundscontaininghalo-gensotherthanchlorinewillnotbepresent.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.2.1Thepreferredunitsaremasspercent.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Attentioniscalledtospecificwarningstatementsincorporatedinthetestmethod.2.ReferencedDocuments2.1ASTMStandards:2D1193SpecificationforReagentWaterD4057PracticeforManualSamplingofPetroleumandPetroleumProductsD6299PracticeforApplyingStatisticalQualityAssuranceandControlChartingTechniquestoEvaluateAnalyticalMeasurementSystemPerformance3.SummaryofTestMethod3.1Thesampleisoxidizedbycombustioninahighpressuredecompositiondevicecontainingoxygenunderpressure.(Warning—Strictadherencetoalloftheprovisionsprescribedhereinafterensuresagainstexplosiveruptureofthehighpressuredecompositiondevice,orablow-out,providedthehighpressuredecompositiondeviceisofproperdesignandconstructionandingoodmechanicalcondition.Itisdesirable,however,thatthehighpressuredecompositiondevicebeenclosedinashieldofsteelplateatleast13mm(1⁄2–in.)thick,...