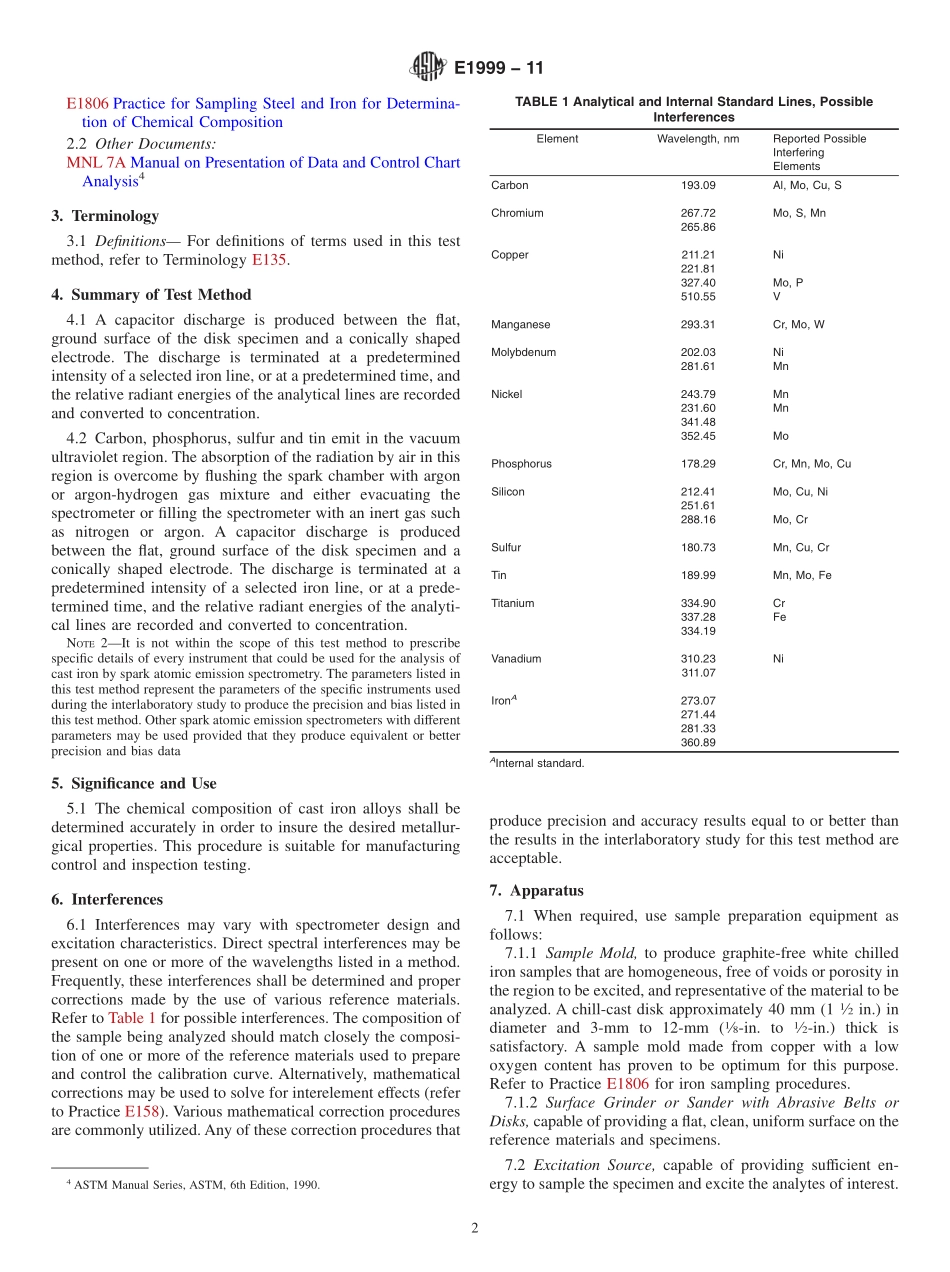

Designation:E1999−11StandardTestMethodforAnalysisofCastIronbySparkAtomicEmissionSpectrometry1ThisstandardisissuedunderthefixeddesignationE1999;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoverstheanalysisofcastironbysparkatomicemissionspectrometryforthefollowingelementsintheconcentrationrangesshown(Note1):ConcentrationRanges,%ElementsApplicableRange,%QuantitativeRange,%ACarbon1.9to3.81.90to3.8Chromium0to2.00.025to2.0Copper0to0.750.015to0.75Manganese0to1.80.03to1.8Molybdenum0to1.20.01to1.2Nickel0to2.00.02to2.0Phosphorus0to0.40.005to0.4Silicon0to2.50.15to2.5Sulfur0to0.080.01to0.08Tin0to0.140.004to0.14Titanium0to0.120.003to0.12Vanadium0to0.220.008to0.22AQuantitativerangeinaccordancewithPracticeE1601.NOTE1—Theconcentrationrangesoftheelementslistedhavebeenestablishedthroughcooperativetestingofreferencematerials.Theseconcentrationrangescanbeextendedbytheuseofsuitablereferencematerials.1.2Thistestmethodcoversanalysisofspecimenshavingadiameteradequatetooverlaptheboreofthesparkstandopening(toeffectanargonseal).Thespecimenthicknessshouldbesufficienttopreventoverheatingduringexcitation.Aheatsinkbackingmaybeused.Themaximumthicknessislimitedonlybytheheightthatthestandwillpermit.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E135TerminologyRelatingtoAnalyticalChemistryforMetals,Ores,andRelatedMaterialsE158PracticeforFundamentalCalculationstoConvertIntensitiesintoConcentrationsinOpticalEmissionSpec-trochemicalAnalysis(Withdrawn2004)3E172PracticeforDescribingandSpecifyingtheExcitationSourceinEmissionSpectrochemical...