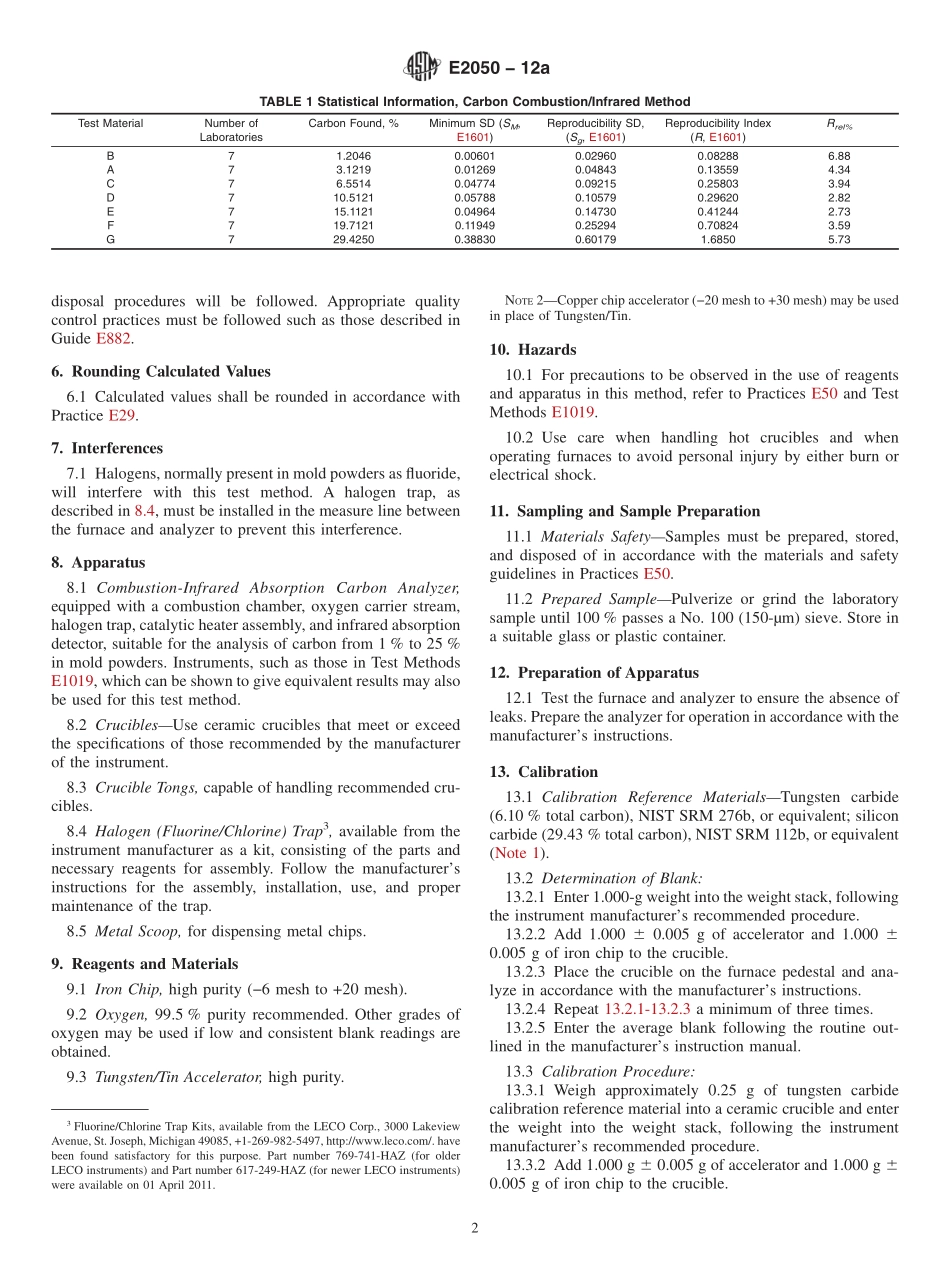

Designation:E2050−12aStandardTestMethodforDeterminationofTotalCarboninMoldPowdersbyCombustion1ThisstandardisissuedunderthefixeddesignationE2050;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationoftotalcarboninmoldpowdersintheconcentrationrangefrom1%to25%.NOTE1—Asusedinthistestmethod,“percentage”or“%”referstoamassfractionoftheform(wt/wt%)(g/100g).1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3ThistestmethodhasbeenevaluatedinaccordancewithPracticeE1601andGuideE1763.Unlessotherwisenotedintheprecisionandbiassection,thelowerlimitinthescopeofeachmethodspecifiesthelowestanalytecontentthatmaybeanalyzedwithacceptableerror(definedasanominal5%riskofobtaininga50%orlargerrelativedifferenceinresultsonthesametestsampleintwolaboratories).1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecificationsE50PracticesforApparatus,Reagents,andSafetyConsid-erationsforChemicalAnalysisofMetals,Ores,andRelatedMaterialsE135TerminologyRelatingtoAnalyticalChemistryforMetals,Ores,andRelatedMaterialsE882GuideforAccountabilityandQualityControlintheChemicalAnalysisLaboratoryE1019TestMethodsforDeterminationofCarbon,Sulfur,Nitrogen,andOxygeninSteel,Iron,Nickel,andCobaltAlloysbyVariousCombustionandFusionTechniquesE1601PracticeforConductinganInterlaboratoryStudytoEvaluatethePerformanceofanAnalyticalMethodE1763GuideforInterpretationandUseofResultsfromInterlaboratoryTestingofChemicalAnalysis...