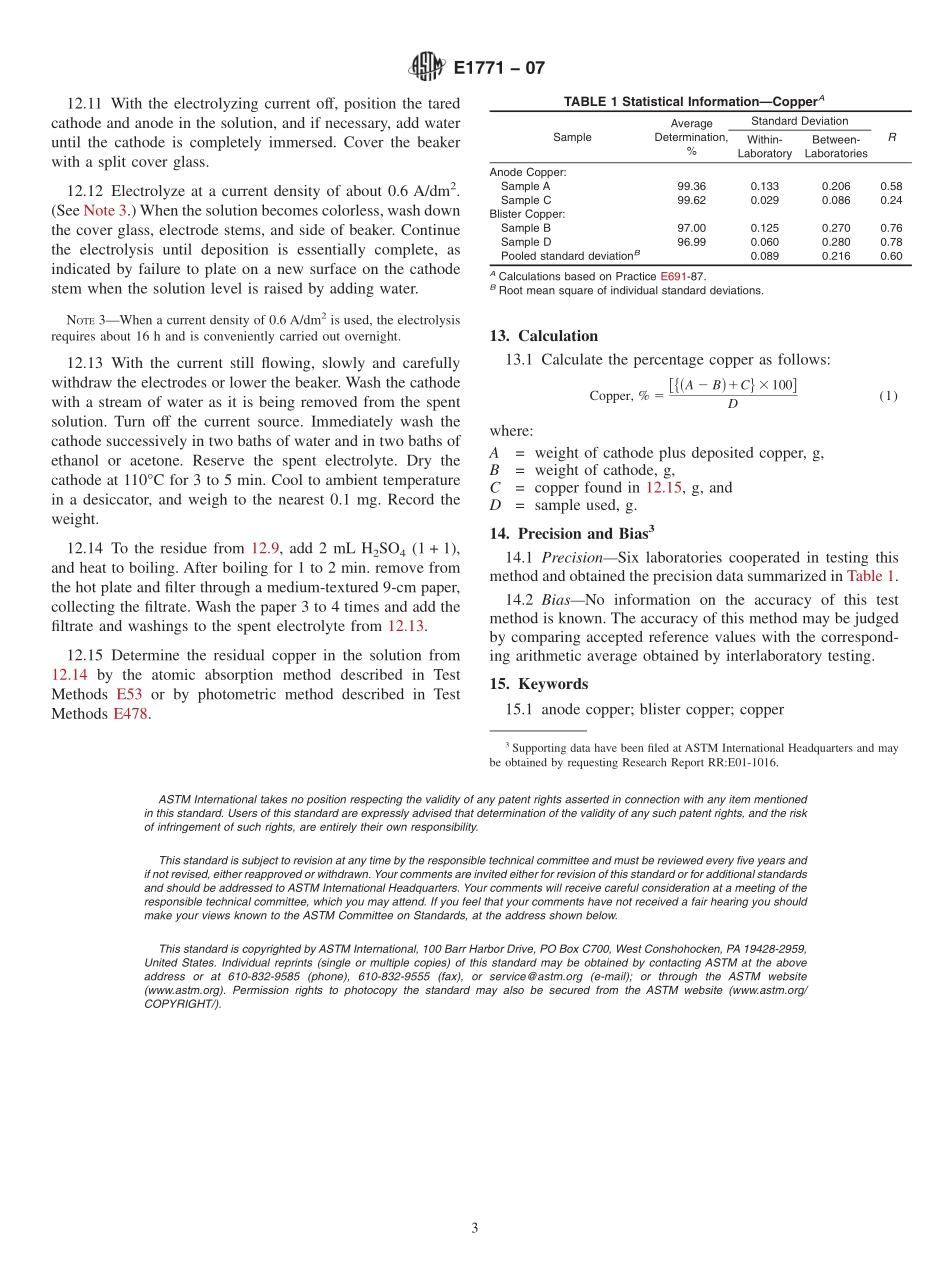

Designation:E1771−07StandardTestMethodforDeterminationofCopperinAnodeandBlisterCopper1ThisstandardisissuedunderthefixeddesignationE1771;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethoddescribestheelectrolyticdeterminationofcopperincommercialanode(99.0to99.8%)andblistercopper(92.0to98.0%).1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.SpecifichazardsstatementsaregiveninSection9.2.ReferencedDocuments2.1ASTMStandards:2E29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecificationsE53TestMethodforDeterminationofCopperinUnalloyedCopperbyGravimetryE135TerminologyRelatingtoAnalyticalChemistryforMetals,Ores,andRelatedMaterialsE255PracticeforSamplingCopperandCopperAlloysfortheDeterminationofChemicalCompositionE478TestMethodsforChemicalAnalysisofCopperAlloysE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1Definitions—Fordefinitionsandtermsusedinthistestmethod,refertoTerminologyE135.4.SummaryofTestMethod4.1Afterdissolutionofthesample,thesolutionisevapo-ratedtodrynessandfumesexpelledbyheat.Thesaltisdissolvedinnitricacid,thesolutionisfiltered,theacidityisadjusted,andthecopperiselectrolyticallyplatedandweighedasthemetal.5.SignificanceandUse5.1Thistestmethodforthedeterminationofcopperinanode(99.0to99.8%)andblistercopper(92.0to98.0%)isprimarilyintendedasarefereemethod,totestsuchmaterialsforcompliancewithcompositionalspecifications.Itisassumedthatusersofthistestmethodwillbetrainedanalystscapableofperformingcommonlaboratoryproceduresskillfullyandsafely.Itisexpectedthatworkwillbeperformed...