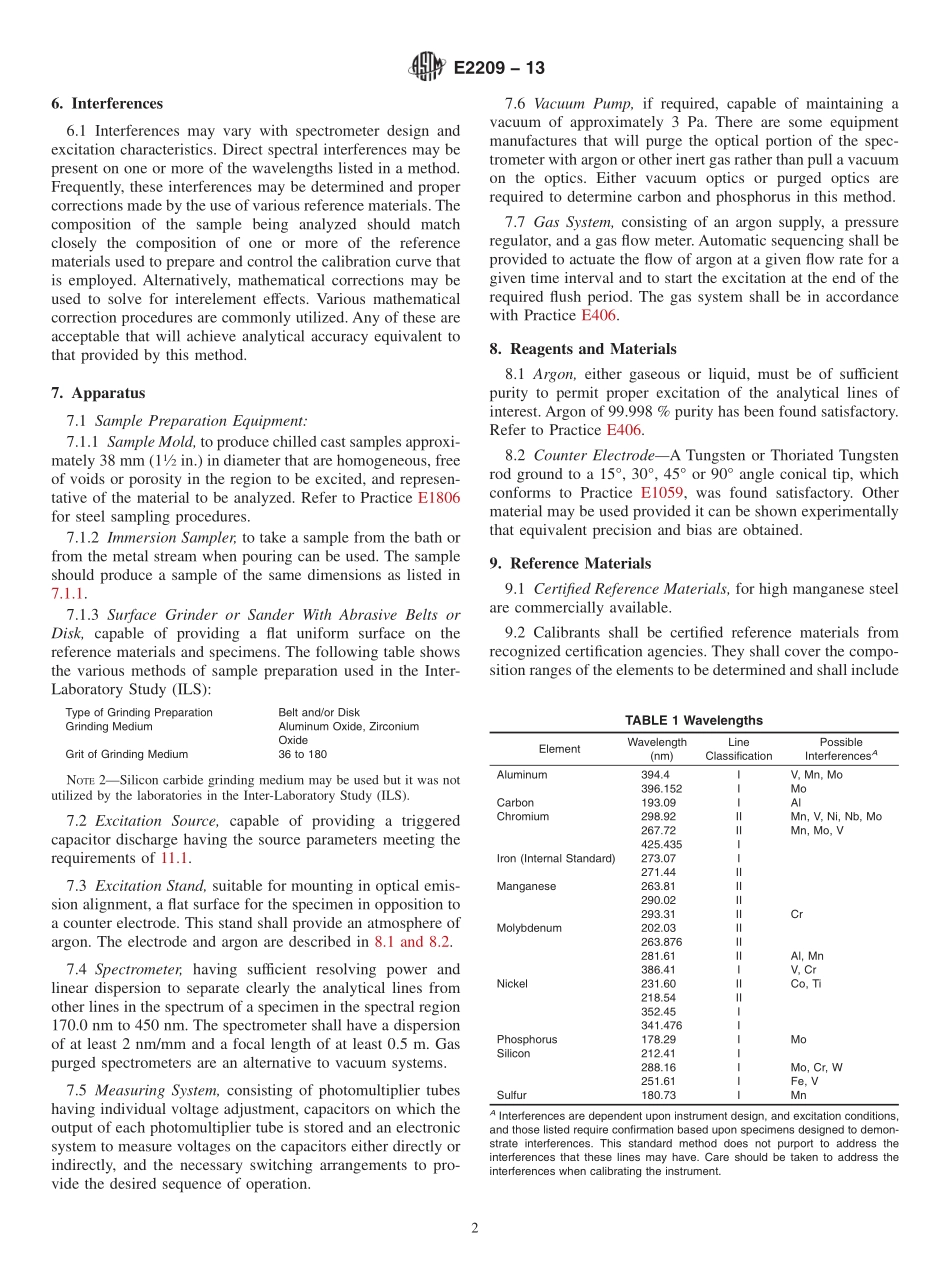

Designation:E2209−13StandardTestMethodforAnalysisofHighManganeseSteelbySparkAtomicEmissionSpectrometry1ThisstandardisissuedunderthefixeddesignationE2209;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodprovidesfortheanalysisofhighmanganesesteelbysparkatomicemissionspectrometryforthefollowingelementsintherangesshown:ElementsConpositionRange,%Aluminum(Al)0.02to0.15Carbon(C)0.3to1.4Chromium(Cr)0.25to2.00Manganese(Mn)8.0to16.2Molybdenum(Mo)0.03to2.0Nickel(Ni)0.05to4.0Phosphorus(P)0.025to0.06Silicon(Si)0.25to1.5NOTE1—Therangesrepresenttheactuallevelsatwhichthismethodwastested.2Thesecompositionrangescanbeextendedtohighercompositionsbytheuseofsuitablereferencematerials.Sulfurisnotincludedbecausedifferencesinresultsbetweenlaboratoriesexceededacceptablelimitsatallanalytelevels.1.2Thistestmethodmayinvolvehazardousmaterials,operations,andequipment.Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3A128/A128MSpecificationforSteelCastings,AusteniticManganeseE135TerminologyRelatingtoAnalyticalChemistryforMetals,Ores,andRelatedMaterialsE305PracticeforEstablishingandControllingAtomicEmissionSpectrochemicalAnalyticalCurvesE353TestMethodsforChemicalAnalysisofStainless,Heat-Resisting,Maraging,andOtherSimilarChromium-Nickel-IronAlloysE406PracticeforUsingControlledAtmospheresinSpec-trochemicalAnalysisE1019TestMethodsforDeterminationofCarbon,Sulfur,Nitrogen,andOxygeninSteel,Iron,Nickel,andCobaltAlloysbyVariousCombustionandFusionTechniquesE1059PracticeforDesignatingShapesandSizesofNon-graphiteCounterElectrodes(Withdrawn2013)4E1329Prac...