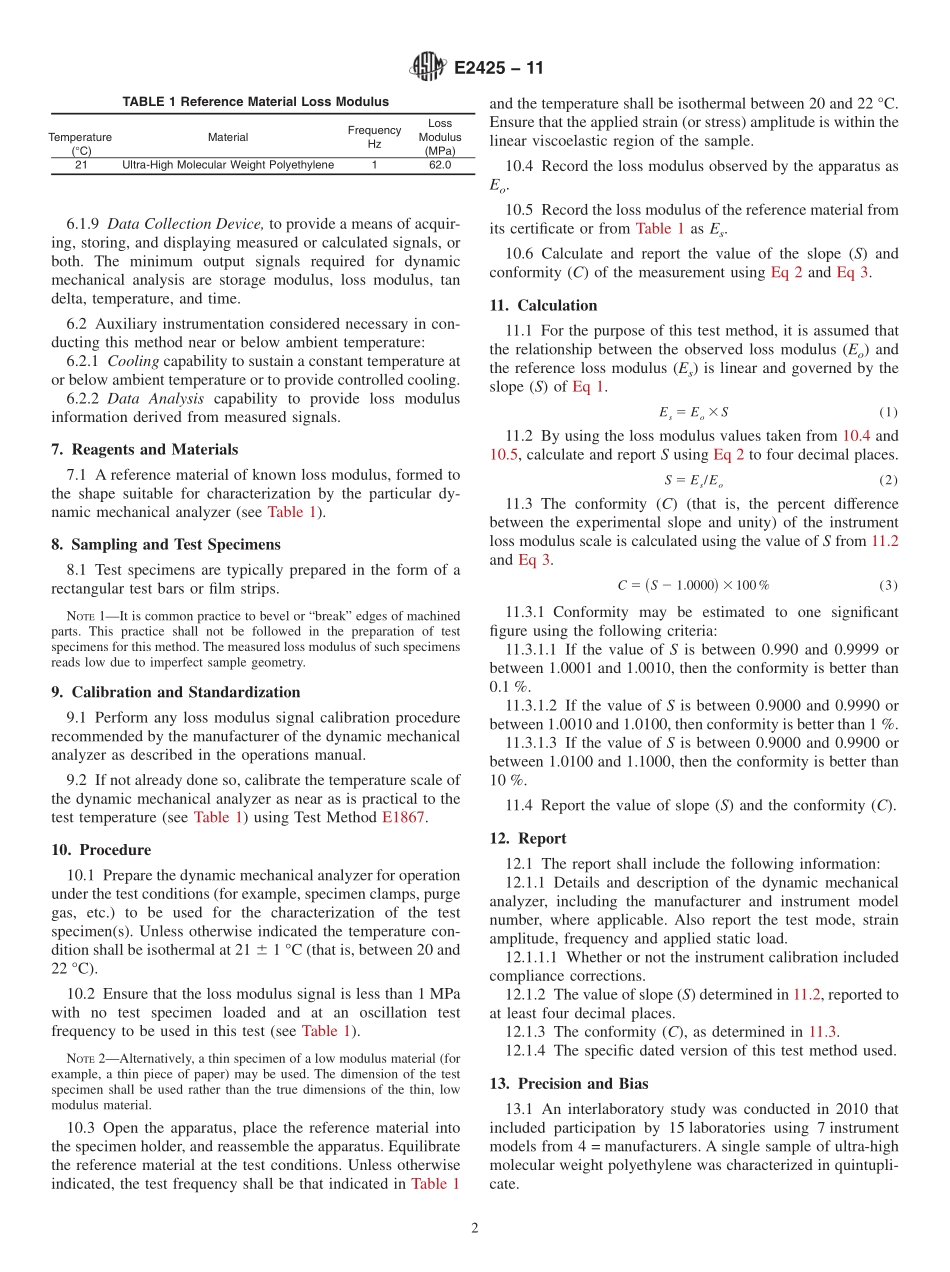

Designation:E2425−11StandardTestMethodforLossModulusConformanceofDynamicMechanicalAnalyzers1ThisstandardisissuedunderthefixeddesignationE2425;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethoddescribestheperformanceconfirma-tionormeasurementofconformanceforthelossmodulusscaleofacommercialorcustom-builtdynamicmechanicalanalyzer(DMA)at21°Cusingultra-highmolecularweightpolyethyl-eneasareferencematerial.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3ThereisnoISOstandardequivalenttothistestmethod.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesandtodeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E473TerminologyRelatingtoThermalAnalysisandRhe-ologyE1142TerminologyRelatingtoThermophysicalPropertiesE1867TestMethodforTemperatureCalibrationofDynamicMechanicalAnalyzers3.Terminology3.1Definitions—SpecifictechnicaltermsusedinthistestmethodaredefinedinTerminologiesE473andE1142includ-ingCelsius,dynamicmechanicalanalysisandlossmodulus.4.SummaryofTestMethod4.1Thelossmodulussignalmeasuredbyadynamicme-chanicalanalyzerforanelasticmaterialiscomparedtothereportedlossmodulusforthatreferencematerial.Alinearrelationshipisusedtocorrelatetheexperimentallossmodulussignalwiththereportedvalueofthereferencematerial.4.2Themodeofdeformation(forexample,tensile,flexure,compression,shear.etc.)shallbereported.5.SignificanceandUse5.1Thistestmethoddemonstratesconformityofadynamicmechanicalanalyzeratanisothermaltemperatureof21°C.5.2Dynamicmechanicalanalysisexperimentsoftenuselineartemperaturechange.Thistestmethoddoesnotaddresstheeffect...