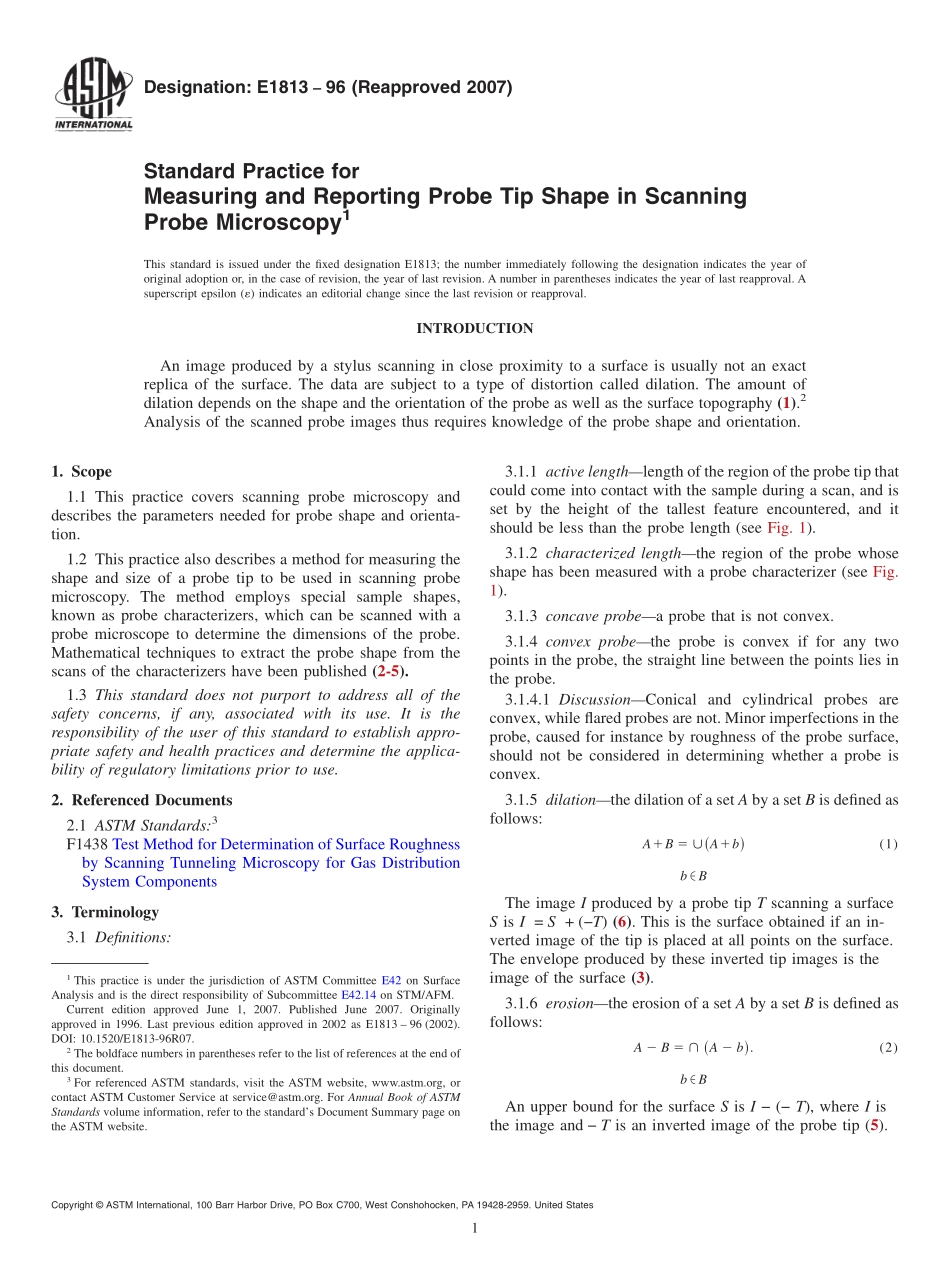

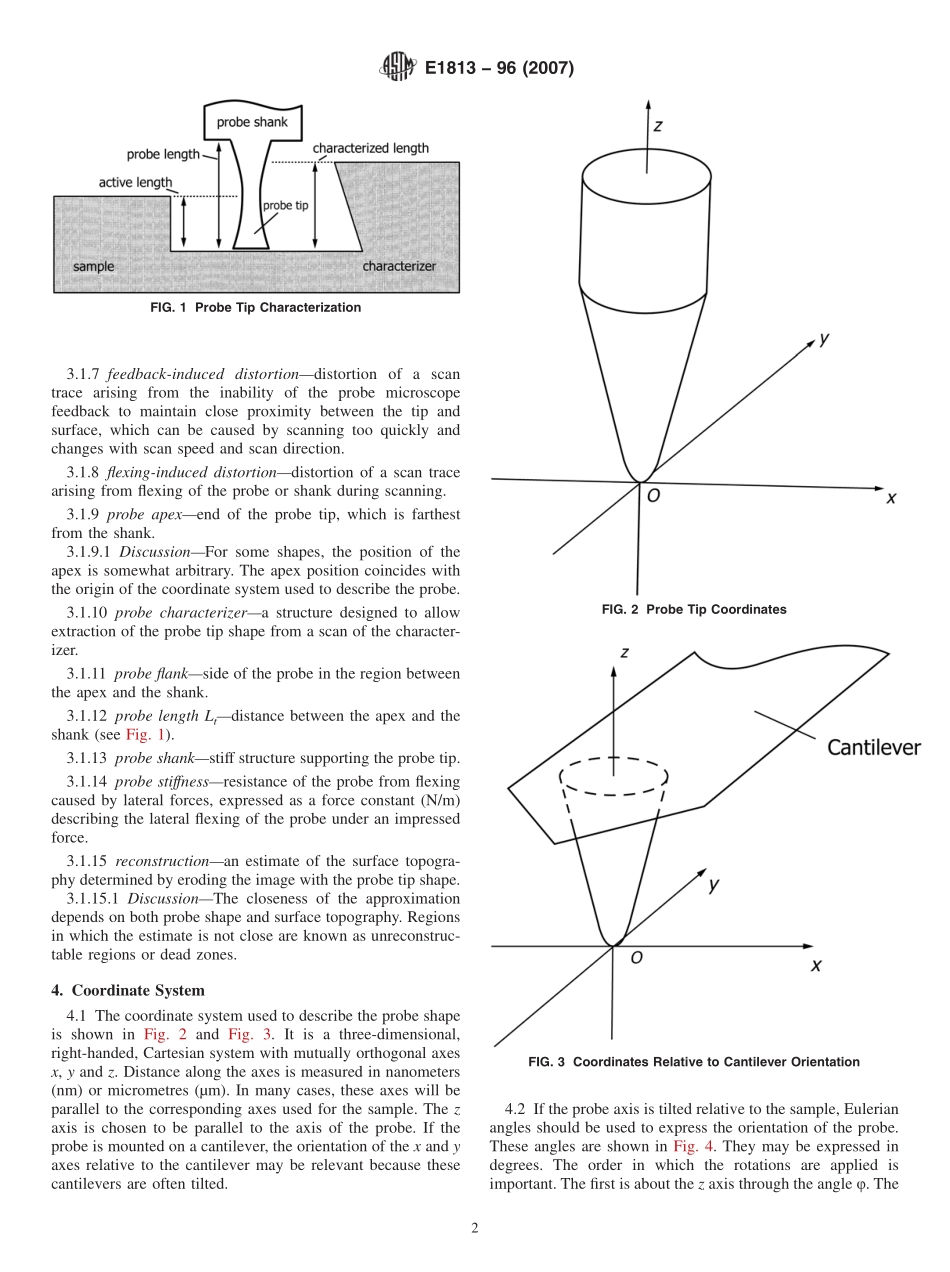

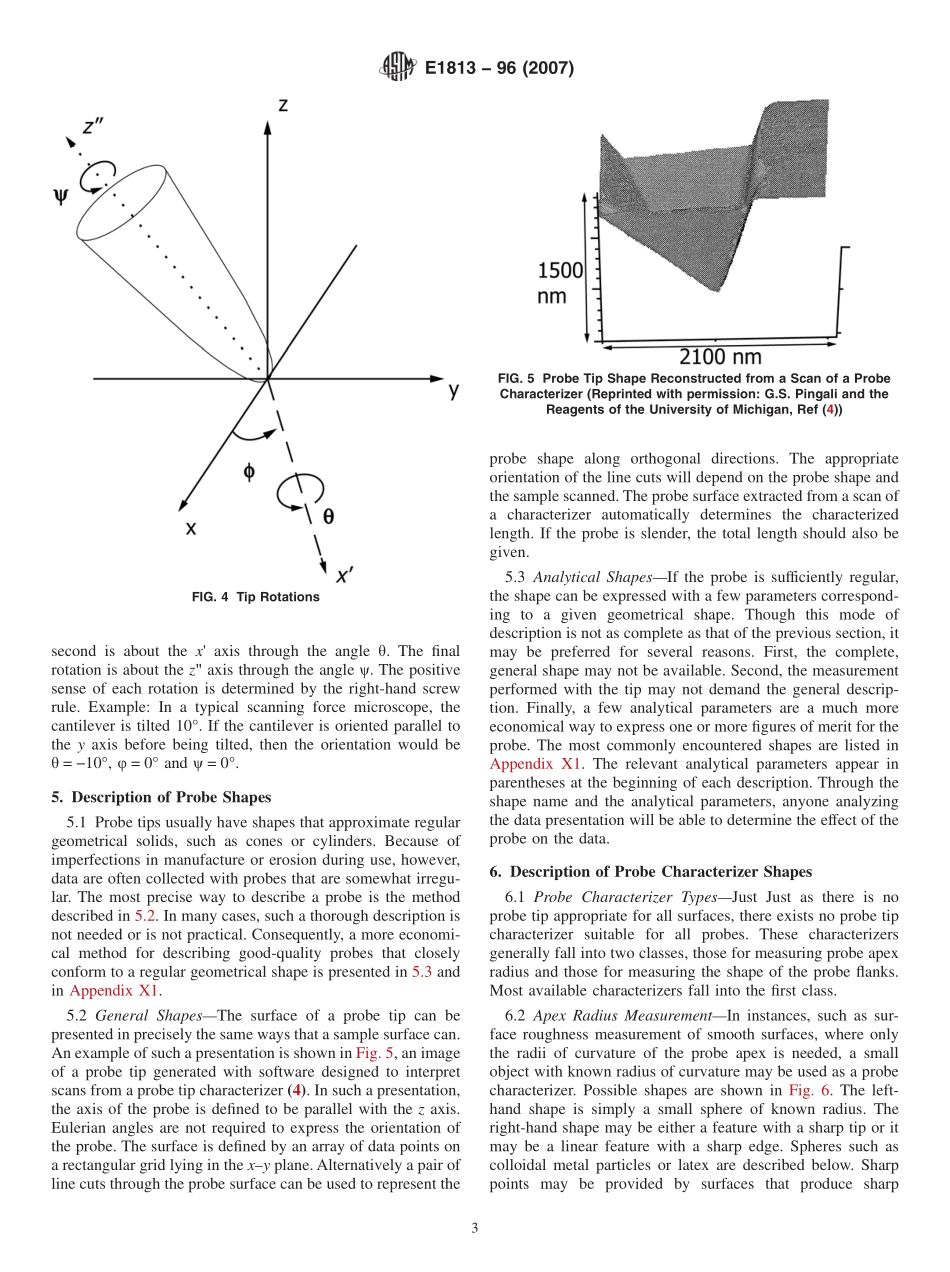

Designation:E1813−96(Reapproved2007)StandardPracticeforMeasuringandReportingProbeTipShapeinScanningProbeMicroscopy1ThisstandardisissuedunderthefixeddesignationE1813;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.INTRODUCTIONAnimageproducedbyastylusscanningincloseproximitytoasurfaceisusuallynotanexactreplicaofthesurface.Thedataaresubjecttoatypeofdistortioncalleddilation.Theamountofdilationdependsontheshapeandtheorientationoftheprobeaswellasthesurfacetopography(1).2Analysisofthescannedprobeimagesthusrequiresknowledgeoftheprobeshapeandorientation.1.Scope1.1Thispracticecoversscanningprobemicroscopyanddescribestheparametersneededforprobeshapeandorienta-tion.1.2Thispracticealsodescribesamethodformeasuringtheshapeandsizeofaprobetiptobeusedinscanningprobemicroscopy.Themethodemploysspecialsampleshapes,knownasprobecharacterizers,whichcanbescannedwithaprobemicroscopetodeterminethedimensionsoftheprobe.Mathematicaltechniquestoextracttheprobeshapefromthescansofthecharacterizershavebeenpublished(2-5).1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3F1438TestMethodforDeterminationofSurfaceRoughnessbyScanningTunnelingMicroscopyforGasDistributionSystemComponents3.Terminology3.1Definitions:3.1.1activelength—lengthoftheregionoftheprobetipthatcouldcomeintocontactwiththesampleduringascan,andissetbytheheightofthetallestfeatureencountered,anditshouldbelessthantheprobelength(seeFig.1).3.1.2characterizedlength—theregionoftheprobewhoseshapehasbeenmeasuredwithaprobecharacterizer(seeFig.1).3.1.3concaveprobe—aprobethatisnotconvex.3.1.4convexprobe—theprob...