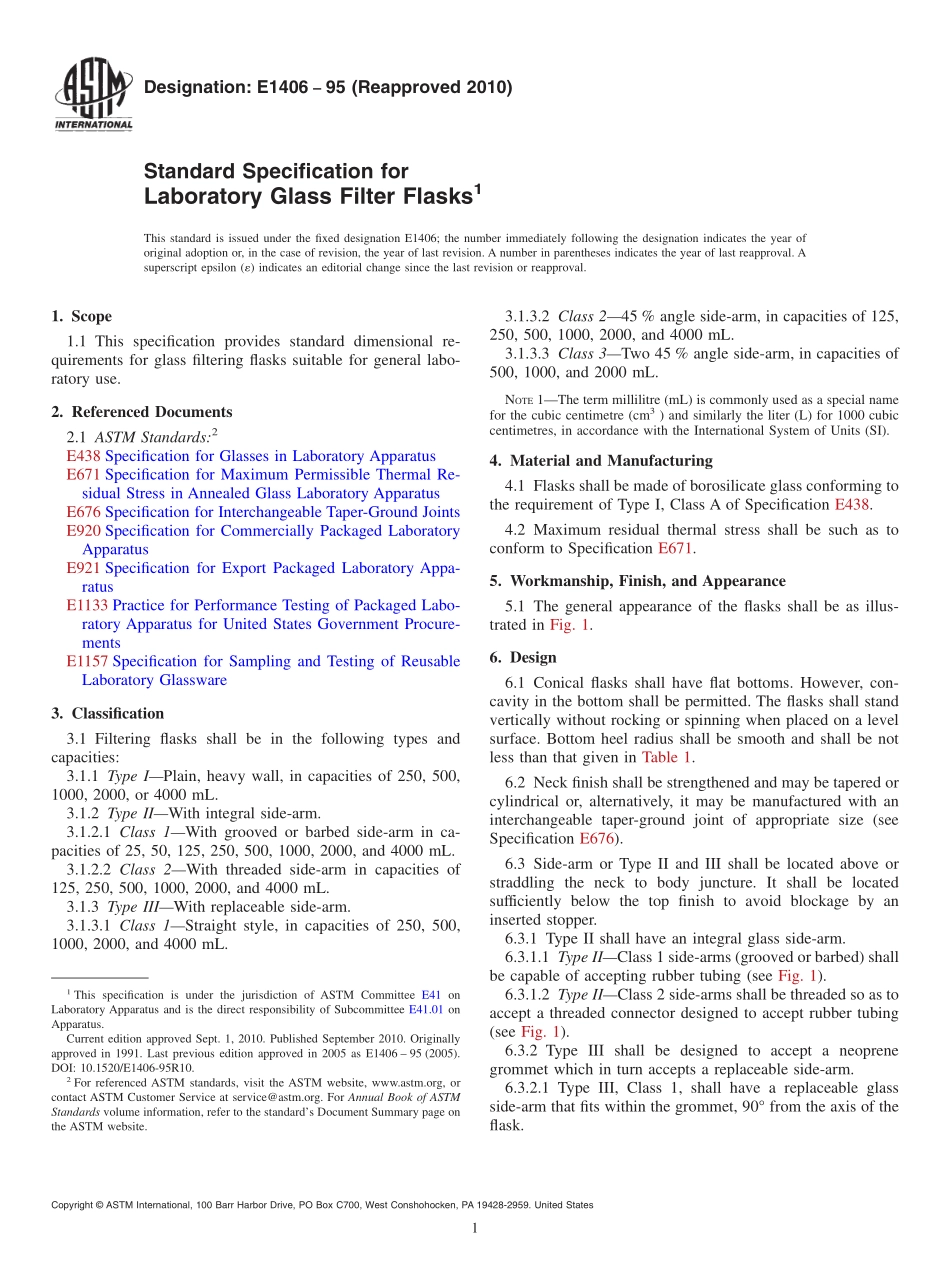

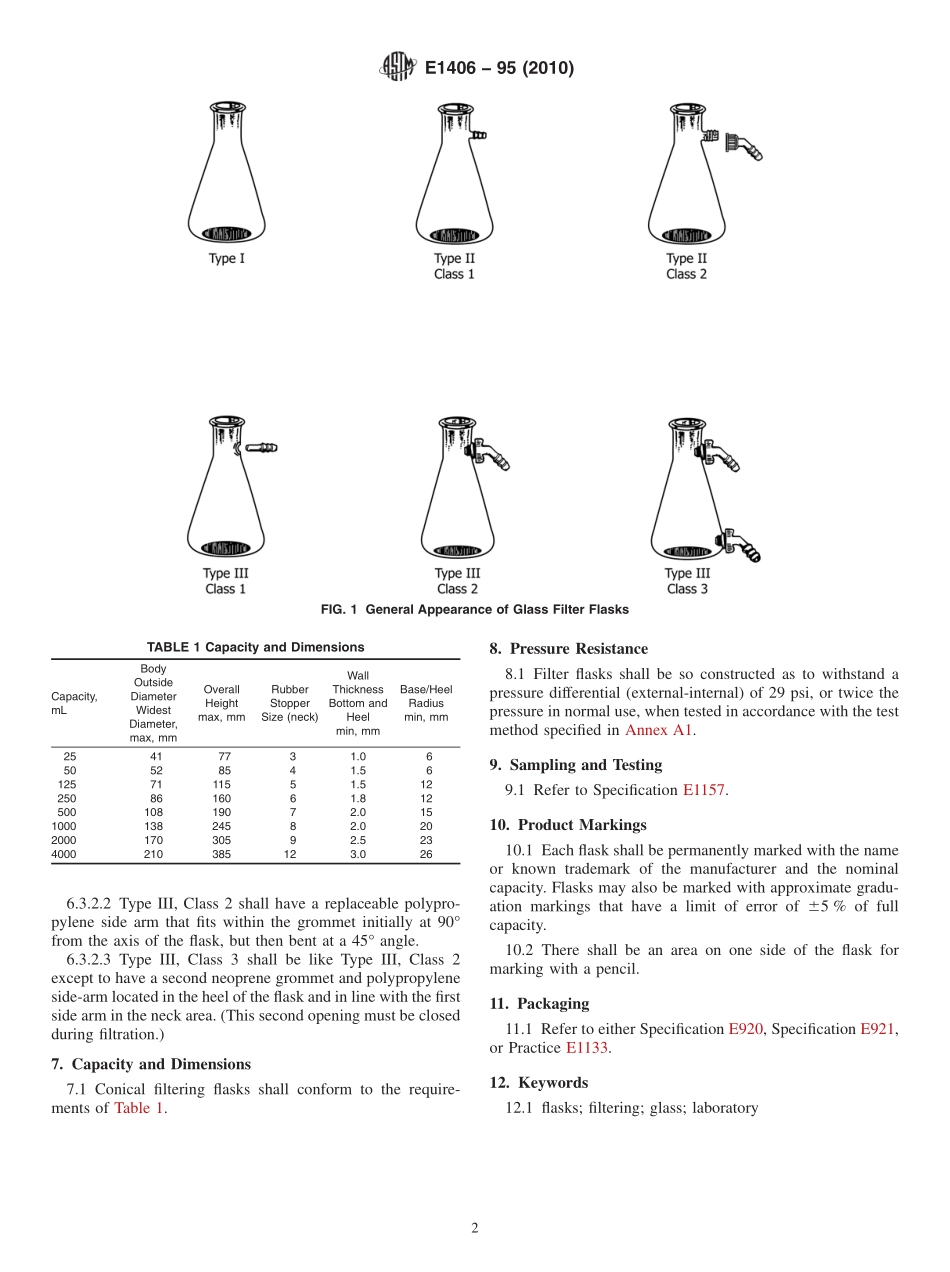

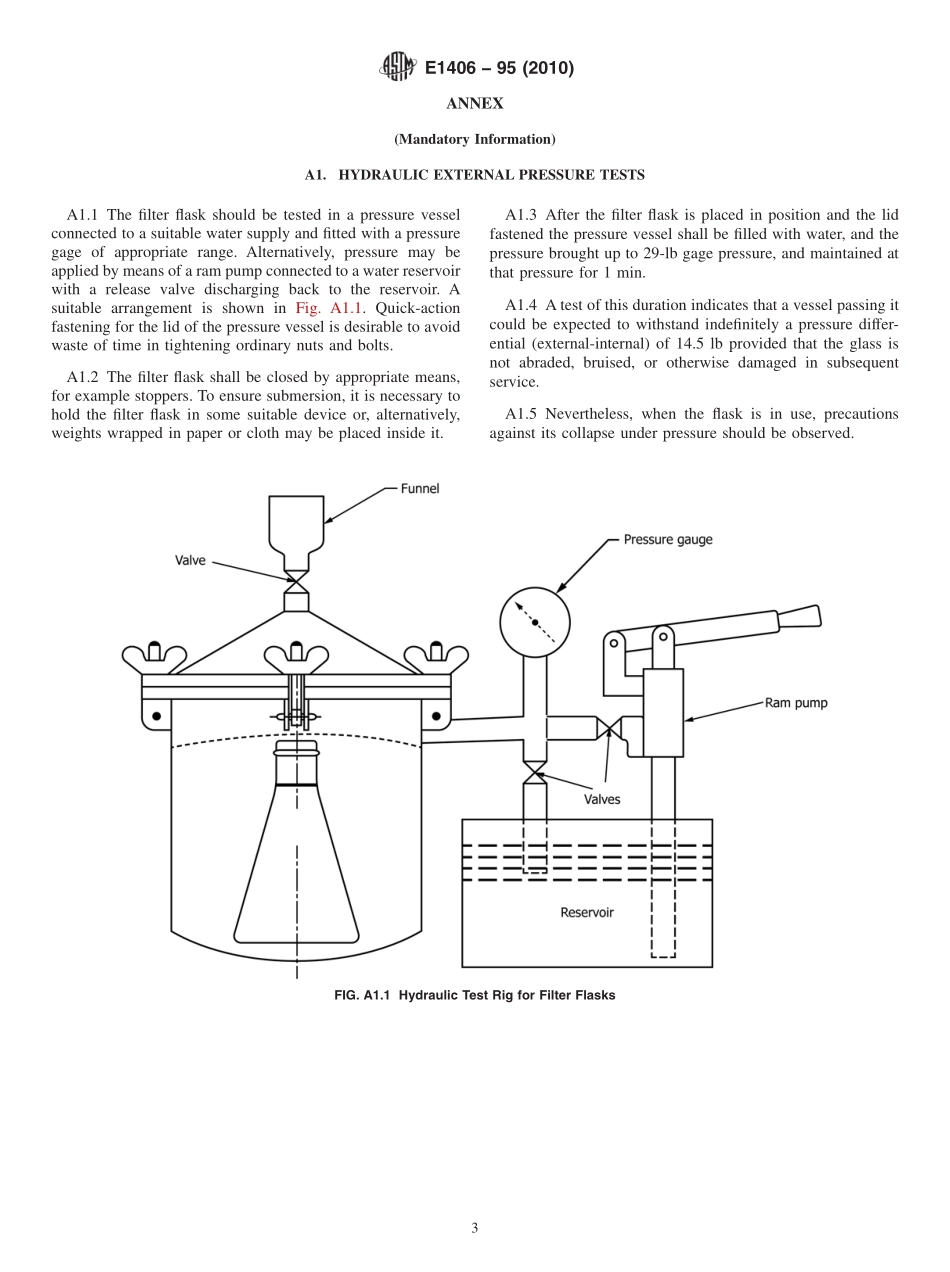

Designation:E1406−95(Reapproved2010)StandardSpecificationforLaboratoryGlassFilterFlasks1ThisstandardisissuedunderthefixeddesignationE1406;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationprovidesstandarddimensionalre-quirementsforglassfilteringflaskssuitableforgenerallabo-ratoryuse.2.ReferencedDocuments2.1ASTMStandards:2E438SpecificationforGlassesinLaboratoryApparatusE671SpecificationforMaximumPermissibleThermalRe-sidualStressinAnnealedGlassLaboratoryApparatusE676SpecificationforInterchangeableTaper-GroundJointsE920SpecificationforCommerciallyPackagedLaboratoryApparatusE921SpecificationforExportPackagedLaboratoryAppa-ratusE1133PracticeforPerformanceTestingofPackagedLabo-ratoryApparatusforUnitedStatesGovernmentProcure-mentsE1157SpecificationforSamplingandTestingofReusableLaboratoryGlassware3.Classification3.1Filteringflasksshallbeinthefollowingtypesandcapacities:3.1.1TypeI—Plain,heavywall,incapacitiesof250,500,1000,2000,or4000mL.3.1.2TypeII—Withintegralside-arm.3.1.2.1Class1—Withgroovedorbarbedside-arminca-pacitiesof25,50,125,250,500,1000,2000,and4000mL.3.1.2.2Class2—Withthreadedside-armincapacitiesof125,250,500,1000,2000,and4000mL.3.1.3TypeIII—Withreplaceableside-arm.3.1.3.1Class1—Straightstyle,incapacitiesof250,500,1000,2000,and4000mL.3.1.3.2Class2—45%angleside-arm,incapacitiesof125,250,500,1000,2000,and4000mL.3.1.3.3Class3—Two45%angleside-arm,incapacitiesof500,1000,and2000mL.NOTE1—Thetermmillilitre(mL)iscommonlyusedasaspecialnameforthecubiccentimetre(cm3)andsimilarlytheliter(L)for1000cubiccentimetres,inaccordancewiththeInternationalSystemofUnits(SI).4.MaterialandManufacturing4.1FlasksshallbemadeofborosilicateglassconformingtotherequirementofTypeI,ClassAofSpecificationE438.4.2Maximumresidualthermalstressshallbesuchastocon...