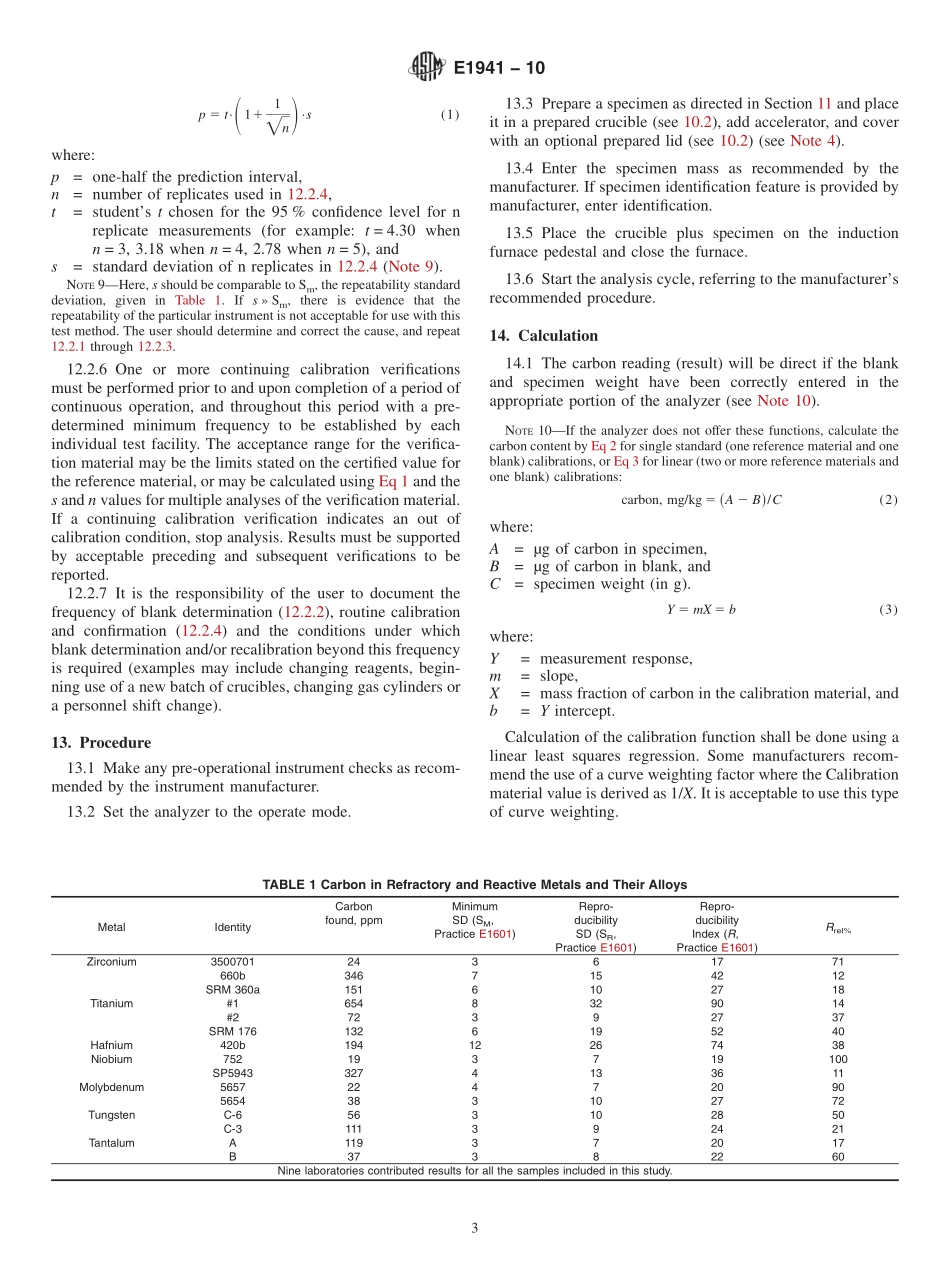

Designation:E1941−10StandardTestMethodforDeterminationofCarboninRefractoryandReactiveMetalsandTheirAlloysbyCombustionAnalysis1ThisstandardisissuedunderthefixeddesignationE1941;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodappliestothedeterminationofcarboninrefractoryandreactivemetalsandtheiralloysinquantitiesfrom20µgto500µg.Thiscorrespondstomassfractionsrangingfrom0.004wt%to0.100wt%fora0.5gsample(seeNote1).NOTE1—Actualquantitativerangemightvaryfrommanufacturertomanufacturerandaccordingtosamplemass.Samplesofhighermassmayallowforproportionallylowerdetectionlimitsprovidedcompletecom-bustionofthesampleisassured.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Specificprecau-tionarystatementsaregiveninSection9.2.ReferencedDocuments2.1ASTMStandards:2E50PracticesforApparatus,Reagents,andSafetyConsid-erationsforChemicalAnalysisofMetals,Ores,andRelatedMaterialsE135TerminologyRelatingtoAnalyticalChemistryforMetals,Ores,andRelatedMaterialsE1601PracticeforConductinganInterlaboratoryStudytoEvaluatethePerformanceofanAnalyticalMethod3.Terminology3.1Definitions—Fordefinitionsoftermsusedinthistestmethod,seeTerminologyE135.4.SummaryofTestMethod4.1Themetalspecimen,containedinasingle-useceramiccrucible,isignited(combusted)inanoxygenatmosphereinaninductionfurnace.Thecarboninthespecimenisoxidizedtocarbondioxideorcarbonmonoxide,orboth,andiseventuallycarriedtotheanalyzer/detector.Theamountofcarbonpresentiselectronicallyprocessedandisdisplayedbytheanalyzerreadout.4.2Thistestmethodiswrittenforusewithcommerciallyavailableanalyzersequippedtocarryouttheaboveoperation...