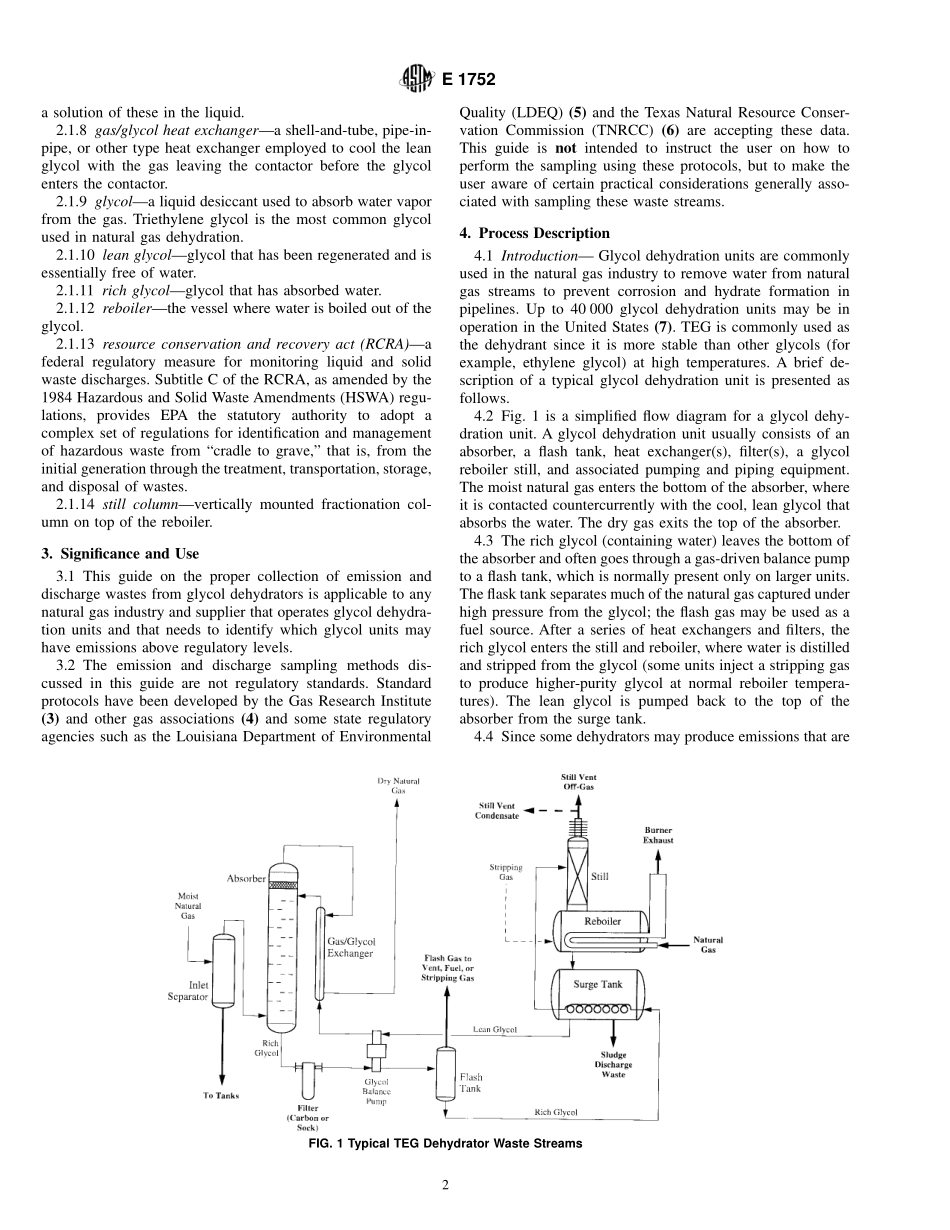

Designation:E1752–95(Reapproved2000)e1StandardGuideforCollectionofMulti-MediaFieldEmissionandDischargeDataAssociatedwithGlycolDehydrationUnits1ThisstandardisissuedunderthefixeddesignationE1752;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.e1NOTE—Subsections6.3.4and7.2.5werecorrectededitoriallyinNovember2000.1.Scope1.1Purpose—Thisguidecoversthepropercollectionoffieldemissionanddischargedataassociatedwithglycoldehydrationunitsusedinthenaturalgasproduction,process-ing,transmission,storage,anddistributionindustries.1.2Background:1.2.1Increasingregulatorypressurehasmadeemissionsofbenzene,toluene,ethylbenzene,andxyleneisomers(collec-tivelyknownasBTEX)andvolatileorganiccompounds(VOCs)fromthestillventofglycoldehydrationunitsamajorconcernofthenaturalgasindustry.TheCleanAirActAmendments(CAAA)of1990havebeentheimpetusforairtoxicsregulations,andseveralstatesareregulatingorareconsideringregulatingemissionsfromglycolunits(1).2LiquidandsolidwastedischargesareexemptfromSubtitleC(haz-ardouswaste)regulationundertheResourceConservationandRecoveryAct(RCRA),butmayberegulatedinthefuture(2).1.2.2Measurementofthewastestreamsfromdehydratorsisimportanttodeterminewhichunitsmayhaveemissionsabovelevelsofregulatoryconcern.MeasurementsofairemissionsfromglycoldehydrationunitshavebeenmadefromavarietyofsamplingpointsusingdifferentsamplingprotocolsandanalyticaltechniquessincenostandardmethodshavebeendevelopedbytheUnitedStatesEnvironmentalProtectionAgency(USEPA)orstateregulatoryagencies.Standardsam-plingmethodsdonotexistfortheliquidandsolidwastestreamssincetheyareexemptfromRCRASubtitleC.Thelackofstandardprotocolshasmeantthatvariationsofthisapproachcanresultinverydifferentemissionsmeasurements(3).1.2.3Providingguidanceonthecollectionoffieldemissionanddischargedatawillallowthenaturalgasindust...