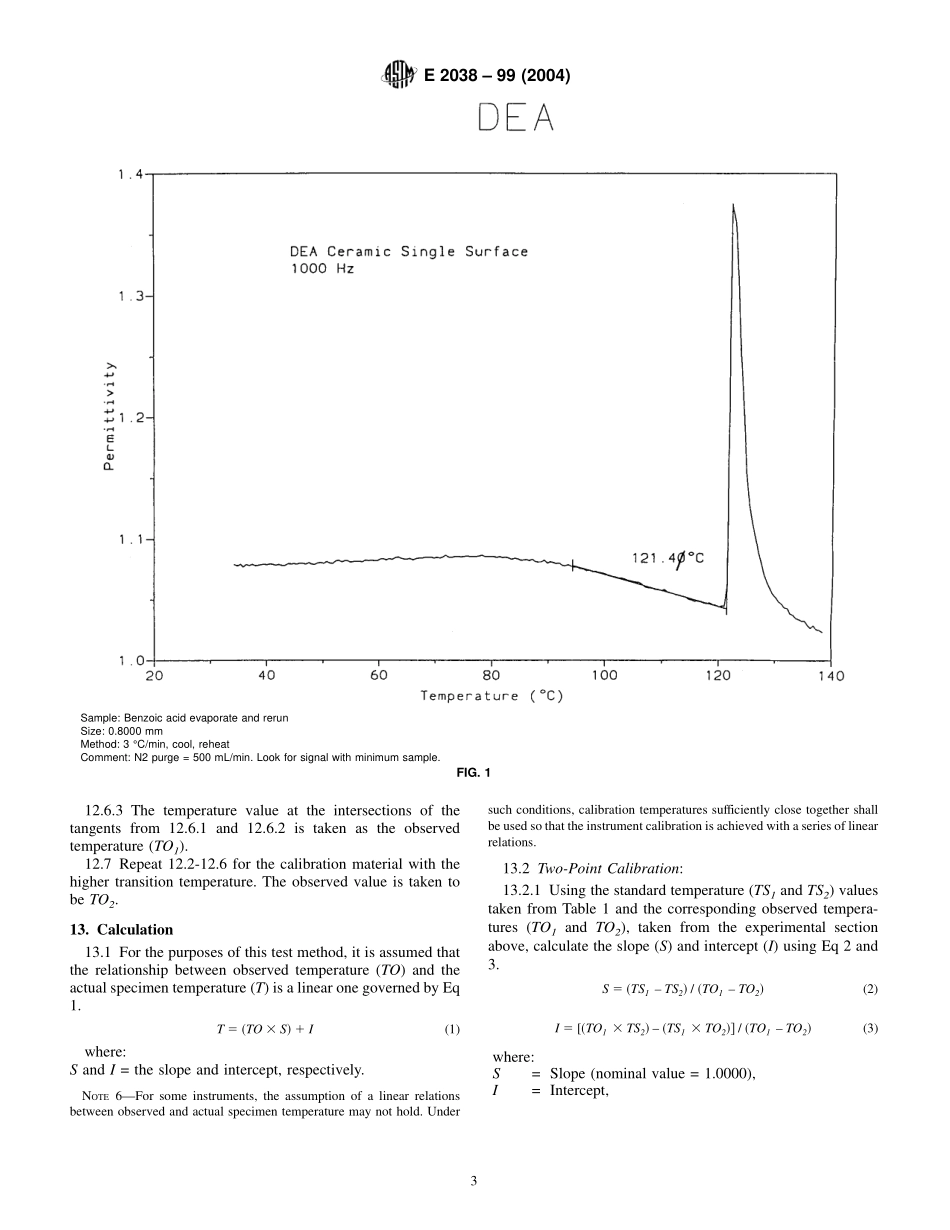

Designation:E2038–99(Reapproved2004)StandardTestMethodforTemperatureCalibrationofDielectricAnalyzers1ThisstandardisissuedunderthefixeddesignationE2038;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethoddescribesthetemperaturecalibrationofdielectricanalyzersoverthetemperaturerangefrom–100to300°Candisapplicabletocommercialandcustom-builtapparatus.Thecalibrationisperformedbyobservingthemeltingtransitionofstandardreferencematerialshavingknowntransitiontemperatureswithinthetemperaturerangeofuse.1.2Electronicinstrumentationorautomateddataanalysisanddatareductionssystemsortreatmentequivalenttothistestmethodmaybeused.1.3ThevaluesstatedinSIunitsaretobereportedasthestandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesandtodeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E473TerminologyRelatingtoThermalAnalysisE1142TerminologyRelatingtoThermophysicalProperties3.Terminology3.1Definitions—SpecifictechnicaltermsusedinthistestmethodaredefinedinaccordancewithTerminologiesE473andE1142.4.SummaryofTestMethod4.1Atestspecimenofknownsolid-solidorsolid-liquid(melting)transitiontemperatureischaracterizedforitsdielec-tricpropertiesinadielectricanalyzerofinterestasafunctionoftemperature.Atthetransition,asharpchangeinthedielectricpropertiesisobserved.Thetemperatureobservedforthetransitionbytheapparatusisrecorded.Usingalinearequation,foroneormoretransitions,thetemperaturescaleorreadoutoftheapparatusiscalibratedbasedupontheknownandobservedtransitiontemperatures.5.SignificanceandUse5.1Thistestmethodpermitsinterlaboratorycomparisonandintralaboratorycorrelationofinstrumentaltemperature...